atmel lcd display manufacturer

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

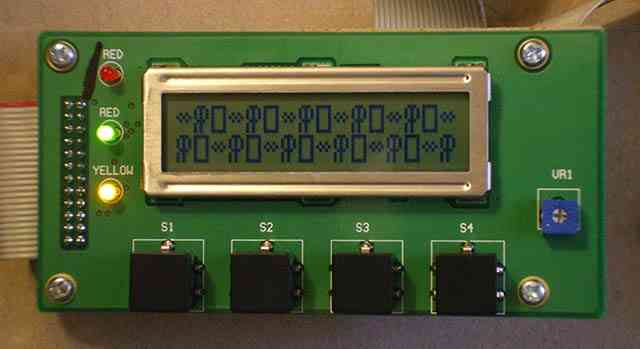

The following is a tutorial on using the ST7920 LCD with the ATmega328 microcontroller using Atmel Studio via the SPI interface. I have used the U8g2 Library, https://github.com/olikraus/u8g2

There are many tutorials on how to control the LCD using an Arduino, but I couldn"t find many on how to use the LCD in Atmel Studio. There was a great one here, https://github.com/olikraus/u8g2/wiki/u8g2as7 which I used to learn how to do this, but several fine details were missing, which made it hard to follow.

I assume that you have the microcontroller working in Atmel Studio. There are plenty of tutorials on how to set up the ATmega328 on a breadboard and get a simple blink program working in Atmel Studio. These are some great ones:

We are using SPI communication, so we select that setup line and paste it into the Atmel main function as shown in the last image. The following line is copied into the main function, replacing the original setup line.

2. If the LCD does not have a potentiometer soldered to the back, attach a resistor with a value of between 200 to 10000 ohms to pin VO as seen above. Adjust the value of the resistor to achieve an optimal contrast. Alternatively, a potentiometer could be used to adjust the contrast.

The following is a tutorial on using the ST7920 LCD with the ATmega328 microcontroller using Atmel Studio via the SPI interface. I have used the U8g2 Library, https://github.com/olikraus/u8g2

There are many tutorials on how to control the LCD using an Arduino, but I couldn"t find many on how to use the LCD in Atmel Studio. There was a great one here, https://github.com/olikraus/u8g2/wiki/u8g2as7 which I used to learn how to do this, but several fine details were missing, which made it hard to follow.

I assume that you have the microcontroller working in Atmel Studio. There are plenty of tutorials on how to set up the ATmega328 on a breadboard and get a simple blink program working in Atmel Studio. These are some great ones:

We are using SPI communication, so we select that setup line and paste it into the Atmel main function as shown in the last image. The following line is copied into the main function, replacing the original setup line.

2. If the LCD does not have a potentiometer soldered to the back, attach a resistor with a value of between 200 to 10000 ohms to pin VO as seen above. Adjust the value of the resistor to achieve an optimal contrast. Alternatively, a potentiometer could be used to adjust the contrast.

An early Arduino boardRS-232 serial interface (upper left) and an Atmel ATmega8 microcontroller chip (black, lower right); the 14 digital I/O pins are at the top, the 6 analog input pins at the lower right, and the power connector at the lower left.

Most Arduino boards consist of an Atmel 8-bit AVR microcontroller (ATmega8,ATmega328, ATmega1280, or ATmega2560) with varying amounts of flash memory, pins, and features.Arduino Due, based on the Atmel SAM3X8E was introduced in 2012.shields. Multiple and possibly stacked shields may be individually addressable via an I2C serial bus. Most boards include a 5 V linear regulator and a 16 MHz crystal oscillator or ceramic resonator. Some designs, such as the LilyPad,

Arduino and Arduino-compatible boards use printed circuit expansion boards called shields, which plug into the normally supplied Arduino pin headers.3D printing and other applications, GNSS (satellite navigation), Ethernet, liquid crystal display (LCD), or breadboarding (prototyping). Several shields can also be made do it yourself (DIY).

A program for Arduino hardware may be written in any programming language with compilers that produce binary machine code for the target processor. Atmel provides a development environment for their 8-bit AVR and 32-bit ARM Cortex-M based microcontrollers: AVR Studio (older) and Atmel Studio (newer).

The graphic display coordinates and the text display coordinates of the 2.2”screen are two different coordinates systems. The origin of the graphic display coordinates begin from the centre point of the screen while that of the later one begins from the top left hand side of the screen.

The following codes are just one part of the API funciotn description. For more information, please refer to ST7687S Library Introduction and Display Library Introduction.

* @The formal parameter size refers to the text size based on the font(6×8). Size is rounded to the integer greater than 0; if size is 1, the pixel points the font occupied will be 6×8. if it is 2, that will be 12×16. The text out of the screen cannot be displayed;

The function of the program: taking the centre point of the 2.2”screen as the starting point(note: the graphic display coordinates and the text display coordinates are two different coordinates, the centre point of the graphic display coordinates is (64, 64) while that of the later one is (0, 0)), display a character string ”fire” with red text background box, white font and the size of the font 2 on the screen. The formal parameter size of the function to set font size tft.setTextSize (uint8_t size) should be greater than 0 and the text out of the screen cannot be displayed.

The function of the program: use the software image2lcd.exe to extract the bitmap of one image and display it on the centre part of the 2.2”screen(note: for the reason of UNO’s internal memory, the following demo cannot be accepted on UNO since the image file is too large, but it can be displayed on ESP32. So you’d better choose small image file if you want to display it on UNO. ) The parameter selection of the software is provided below.

Shenzhen Topway Technology Co.Ltd. has launched theirTOPWAY Smart TFT LCD module, which embeds LCD driver, controller and MCU, in a color LCD module with digital brain. A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display (LCD) that uses thin-film-transistor (TFT) technology to improve image quality such as brightness and contrast.

A TFT LCD is an active matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven LCDs with a few segments. Smart TFT LCD sets engineer free from tedious display programming, so that product engineer can focus on product development. Smart TFT LCD module can help users greatly reduce product’s time-to-market. And the product is more reliable with high EMI tolerance.

Taking over the duty of displaying content and respond to touch event, Topway launched Smart LCD module couple years ago. Smart LCD is a TFT LCD display module embedded with MCU, display engine and touch controller. Simple serial commands are all that is needed to interact with the screen, no more pixel programming.

Smart LCD module is between traditional TFT LCD module and HMI device. HMI device works as a standalone unit with higher cost. Topway Smart TFT LCD provides a cost effective way to quickly implement human – machine interface:

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey