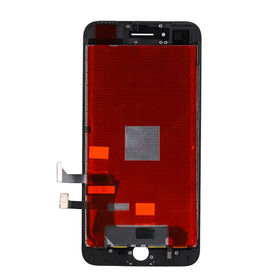

pantalla pls tft lcd factory

Thanks for the display technology development, we have a lot of display choices for our smartphones, media players, TVs, laptops, tablets, digital cameras, and other such gadgets. The most display technologies we hear are LCD, TFT, OLED, LED, QLED, QNED, MicroLED, Mini LED etc. The following, we will focus on two of the most popular display technologies in the market: TFT Displays and Super AMOLED Displays.

TFT means Thin-Film Transistor. TFT is the variant of Liquid Crystal Displays (LCDs). There are several types of TFT displays: TN (Twisted Nematic) based TFT display, IPS (In-Plane Switching) displays. As the former can’t compete with Super AMOLED in display quality, we will mainly focus on using IPS TFT displays.

OLED means Organic Light-Emitting Diode. There are also several types of OLED, PMOLED (Passive Matrix Organic Light-Emitting Diode) and AMOLED (Active Matrix Organic Light-Emitting Diode). It is the same reason that PMOLED can’t compete with IPS TFT displays. We pick the best in OLED displays: Super AMOLED to compete with the LCD best: IPS TFT Display.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

The transmittance of a pixel of an LCD panel typically does not change linearly with the applied voltage,sRGB standard for computer monitors requires a specific nonlinear dependence of the amount of emitted light as a function of the RGB value.

Less expensive PVA panels often use dithering and FRC, whereas super-PVA (S-PVA) panels all use at least 8 bits per color component and do not use color simulation methods.BRAVIA LCD TVs offer 10-bit and xvYCC color support, for example, the Bravia X4500 series. S-PVA also offers fast response times using modern RTC technologies.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

IPS (in-plane switching) is a screen technology for liquid-crystal displays (LCDs). In IPS, a layer of liquid crystals is sandwiched between two glass surfaces. The liquid crystal molecules are aligned parallel to those surfaces in predetermined directions (in-plane). The molecules are reoriented by an applied electric field, whilst remaining essentially parallel to the surfaces to produce an image. It was designed to solve the strong viewing angle dependence and low-quality color reproduction of the twisted nematic field effect (TN) matrix LCDs prevalent in the late 1980s.

The TN method was the only viable technology for active matrix TFT LCDs in the late 1980s and early 1990s. Early panels showed grayscale inversion from up to down,Vertical Alignment (VA)—that could resolve these weaknesses and were applied to large computer monitor panels.

Shortly thereafter, Hitachi of Japan filed patents to improve this technology. A leader in this field was Katsumi Kondo, who worked at the Hitachi Research Center.thin-film transistor array as a matrix and to avoid undesirable stray fields in between pixels.Super IPS). NEC and Hitachi became early manufacturers of active-matrix addressed LCDs based on the IPS technology. This is a milestone for implementing large-screen LCDs having acceptable visual performance for flat-panel computer monitors and television screens. In 1996, Samsung developed the optical patterning technique that enables multi-domain LCD. Multi-domain and in-plane switching subsequently remain the dominant LCD designs through 2006.

In this case, both linear polarizing filters P and A have their axes of transmission in the same direction. To obtain the 90 degree twisted nematic structure of the LC layer between the two glass plates without an applied electric field (OFF state), the inner surfaces of the glass plates are treated to align the bordering LC molecules at a right angle. This molecular structure is practically the same as in TN LCDs. However, the arrangement of the electrodes e1 and e2 is different. Because they are in the same plane and on a single glass plate, they generate an electric field essentially parallel to this plate. The diagram is not to scale: the LC layer is only a few micrometers thick and so is very small compared with the distance between the electrodes.

Toward the end of 2010 Samsung Electronics introduced Super PLS (Plane-to-Line Switching) with the intent of providing an alternative to the popular IPS technology which is primarily manufactured by LG Display. It is an "IPS-type" panel technology, and is very similar in performance features, specs and characteristics to LG Display"s offering. Samsung adopted PLS panels instead of AMOLED panels, because in the past AMOLED panels had difficulties in realizing full HD resolution on mobile devices. PLS technology was Samsung"s wide-viewing angle LCD technology, similar to LG Display"s IPS technology.

In 2012 AU Optronics began investment in their own IPS-type technology, dubbed AHVA. This should not be confused with their long standing AMVA technology (which is a VA-type technology). Performance and specs remained very similar to LG Display"s IPS and Samsung"s PLS offerings. The first 144 Hz compatible IPS-type panels were produced in late 2014 (used first in early 2015) by AUO, beating Samsung and LG Display to providing high refresh rate IPS-type panels.

"TFT Technology: Enhancing the viewing angle". Riverdi (TFT Module Manufacturer). Archived from the original on 23 April 2016. Retrieved 5 November 2016. However, [twisted nematic] suffers from the phenomenon called gray scale inversion. This means that the display has one viewing side in which the image colors suddenly change after exceeding the specified viewing angle. (see image Inversion Effect) External link in |quote= (help)

Baker, Simon (30 April 2011). "Panel Technologies: TN Film, MVA, PVA and IPS Explained". Tftcentral.co.uk. Archived from the original on 29 June 2017. Retrieved 13 January 2012.

"Samsung PLS improves on IPS displays like iPad"s, costs less". electronista.com. Archived from the original on 27 October 2012. Retrieved 30 October 2012.

Cutting edge display technology has been a central feature of flagship smartphones in recent years. The LG V30 arrived late last year with yet another innovation in screen tech: new panel type called P-OLED. With Samsung still marketing its Super AMOLED and Infinity Display technology, and some other manufacturers moving away from the tried and tested IPS LCD, there’s never been more choice for display panel tech in the smartphone market.

P-OLED isn’t exactly the new kid on the block, but the technology is just starting to appear in a number of flagship handsets. We’ve already seen how LG Display’s P-OLED stacks up against Samsung’s AMOLED,but what about the common IPS LCD display technology? That’s what we aim to find out in this P-OLED vs IPS LCD breakdown.

The common LCD stands for Liquid Crystal Display, while IPS stands for “in-plane switching”. The latter controlls the crystal elements in the display’s RGB sub-pixel layout. IPS replaced twisted nematic field effect (TN) as the technology of choice for LCD in the 90s, and is what you’ll find in all LCD-based smartphone panels.

Each sub-pixel is connected up to a thin-film transistor active matrix, which drives the panel’s brightness and color without consuming as much current as an outdated passive matrix display. Using different TFT materials and production techniques can alter the driving properties of the display and alter the transistor sizes, which affects properties such as brightness, viewing angles, and color gamut. Hence why you’ll find a variety of different naming schemes for IPS LCD display, including Super IPS, Super LCD5, and others.

The makeup of the backlight can vary between LCD panels too, as the white light has to be created from another group of colors. The light source can be made up of LEDs or an electroluminescent panel (ELP), among others, each of which can offer a slightly different white tint and varying degrees of even light across their surface.

OLED technology has been the major rival to LCD in the smartphone market for what seems like forever. Samsung’s AMOLED technology has powered generations of the top selling Android flagship. Plastic-OLED (or P-OLED) is simply the latest iteration of this technology, primarily designed to enable new and interesting form factors.

Compared with the numerous layers of an LCD display, P-OLED is considerably less complicated looking. The key component is a Light Emitting Diode (LED). So rather than relying on a universal backlight, each sub-pixel is capable of producing its own red, green, or blue light, or being shut-off completely. The O part in OLED stands for organic, which is the compound type that lights up when current is applied.

To drive this current, the TFT matrix is used in a very similar way to LCD. Although this time the current is used to produce the light rather than twist the polarizing crystals. As this is an active matrix TFT, Samsung chose to call its OLED panels AMOLED. P-OLED shouldn’t be confused with the outdated PMOLED technology, which stands for passive matrix and isn’t used in any modern pieces of high-end display tech.

So where does the plastic element come in? Well it’s simply the material used as the back substrate on which the TFT and OLED components are placed. Historically, this has been made from glass but using a plastic substrate makes the display more malleable and flexible. It’s important to note however, that switching over to a plastic substrate requires new materials for the TFT plane that can withstand the manufacturing temperatures, while still providing sufficient electron mobility and current for the LEDs.

The two display technologies have their own pros and cons in terms of viewing quality, but plastic OLED has a trick up its sleeve that LCD can’t yet match — flexibility.

Although the very top of a smartphone display will likely feature a protective glass layer, such as Gorilla Glass, the underlying plastic substrate layer does offer some additional shock absorption. This means that it’s less likely that the TFT layer will break on dropping, helping to preserve functionality even if the top layer cracks.

It’s worth stating that flexible LCD alternatives are in development. Japan Display showcased its low-cost flexible LCD technology in early 2017 and other companies are working on Organic LCD and similar ideas. However, the trick is still to match flexible OLED for pixel density and resolution, color gamut, and production yield. So it’s likely to be a while before we see competing flexible LCD products.

Unfortunately, there’s no definitive superior technology between IPS LCD and P-OLED. There are too many variables beyond the basic display type that determine the quality of the viewing experience. These include sub-pixel layouts and manufacturing materials.

No two IPS LCD manufacturers are necessarily alike, and even P-OLED will undoubtedly go through generational revisions over the next few years and continue to improve performance. Furthermore, new advances in LCD technology, including Quantum Dot, WRGB, and others, keep reinvigorating the already well-refined technology.

In recent years, smartphone displays have developed far more acronyms than ever before with each different one featuring a different kind of technology. AMOLED, LCD, LED, IPS, TFT, PLS, LTPS, LTPO...the list continues to grow.

There are many display types used in smartphones: LCD, OLED, AMOLED, Super AMOLED, TFT, IPS and a few others that are less frequently found on smartphones nowadays, like TFT-LCD. One of the most frequently found on mid-to-high range phones now is IPS-LCD. But what do these all mean?

LCD means Liquid Crystal Display, and its name refers to the array of liquid crystals illuminated by a backlight, and their ubiquity and relatively low cost make them a popular choice for smartphones and many other devices.

LCDs also tend to perform quite well in direct sunlight, as the entire display is illuminated from behind, but does suffer from potentially less accurate colour representation than displays that don"t require a backlight.

Within smartphones, you have both TFT and IPS displays. TFT stands for Thin Film Transistor, an advanced version of LCD that uses an active matrix (like the AM in AMOLED). Active matrix means that each pixel is attached to a transistor and capacitor individually.

The main advantage of TFT is its relatively low production cost and increased contrast when compared to traditional LCDs. The disadvantage of TFT LCDs is higher energy demands than some other LCDs, less impressive viewing angles and colour reproduction. It"s for these reasons, and falling costs of alternative options, that TFTs are not commonly used in smartphones anymore.Affiliate offer

IPS technology (In-Plane Switching) solves the problem that the first generation of LCD displays experience, which adopts the TN (Twisted Nematic) technique: where colour distortion occurs when you view the display from the side - an effect that continues to crop up on cheaper smartphones and tablets.

The PLS (Plane to Line Switching) standard uses an acronym that is very similar to that of IPS, and is it any wonder that its basic operation is also similar in nature? The technology, developed by Samsung Display, has the same characteristics as IPS displays - good colour reproduction and viewing angles, but a lower contrast level compared to OLED and LCD/VA displays.

According to Samsung Display, PLS panels have a lower production cost, higher brightness rates, and even superior viewing angles when compared to their rival, LG Display"s IPS panels. Ultimately, whether a PLS or IPS panel is used, it boils down to the choice of the component supplier.

This is a very common question after "LED" TVs were launched, with the short answer simply being LCD. The technology used in a LED display is liquid crystal, the difference being LEDs generating the backlight.

One of the highlights from TV makers at the CES 2021 tradeshow, mini-LED technology seemed far removed from mobile devices until Apple announced the 2021 iPad Pro. As the name implies, the technique is based on the miniaturization of the LEDs that form the backlight of the screen — which still uses an LCD panel.

Despite the improvement in terms of contrast (and potentially brightness) over traditional LCD/LED displays, LCD/mini-LEDs still divide the screen into brightness zones — over 2,500 in the case of the iPad and 2021 "QNED" TVs from LG — compared to dozens or hundreds of zones in previous-generation FALD (full-array local dimming) displays, on which the LEDs are behind the LCD panel instead of the edges.

AMOLED stands for Active Matrix Organic Light-Emitting Diode. While this may sound complicated it actually isn"t. We already encountered the active matrix in TFT LCD technology, and OLED is simply a term for another thin-film display technology.

OLED is an organic material that, as the name implies, emits light when a current is passed through it. As opposed to LCD panels, which are back-lit, OLED displays are "always off" unless the individual pixels are electrified.

This means that OLED displays have much purer blacks and consume less energy when black or darker colours are displayed on-screen. However, lighter-coloured themes on AMOLED screens use considerably more power than an LCD using the same theme. OLED screens are also more expensive to produce than LCDs.

Because the black pixels are "off" in an OLED display, the contrast ratios are also higher compared to LCD screens. AMOLED displays have a very fast refresh rate too, but on the downside are not quite as visible in direct sunlight as backlit LCDs. Screen burn-in and diode degradation (because they are organic) are other factors to consider.Affiliate offer

Super AMOLED is the name given by Samsung to its displays that used to only be found in high-end models but have now trickled down to more modestly specced devices. Like IPS LCDs, Super AMOLED improves upon the basic AMOLED premise by integrating the touch response layer into the display itself, rather than as an extra layer on top.

Speaking of pixel density, this was one of Apple"s highlights back in 2010 during the launch of the iPhone 4. The company christened the LCD screen (LED, TFT, and IPS) used in the smartphone as "Retina Display", thanks to the high resolution of the panel used (960 by 640 pixels back then) in its 3.5-inch display.

As a kind of consolation prize for iPhone XR and iPhone 11 buyers, who continued relying on LCD panels, Apple classified the display used in the smartphones with a new term, "Liquid Retina". This was later applied also to the iPad Pro and iPad Air models, with the name defining screens that boast a high range and colour accuracy, at least based on the company"s standards.

TFT(Thin Film Transistor) - a type of LCD display that adopts a thin semiconductor layer deposited on the panel, which allows for active control of the colour intensity in each pixel, featuring a similar concept as that of active-matrix (AM) used in AMOLED displays. It is used in TN, IPS/PLS, VA/PVA/MVA panels, etc.

LTPS(Low Temperature PolySilicon) - a variation of the TFT that offers higher resolutions and lower power consumption compared to traditional TFT screens, based on a-Si (amorphous silicon) technology.

IGZO(Indium Gallium Zinc Oxide) - a semiconductor material used in TFT films, which also allows higher resolutions and lower power consumption, and sees action in different types of LCD screens (TN, IPS, VA) and OLED displays

LTPO(Low Temperature Polycrystaline Oxide) - a technology developed by Apple that can be used in both OLED and LCD displays, as it combines LTPS and IGZO techniques. The result? Lower power consumption. It has been used in the Apple Watch 4 and the Galaxy S21 Ultra.

Among televisions, the long-standing featured technology has always been miniLED - which consists of increasing the number of lighting zones in the backlight while still using an LCD panel. There are whispers going around that smartphones and smartwatches will be looking at incorporating microLED technology in their devices soon, with it being radically different from LCD/LED displays as it sports similar image characteristics to that of OLEDs.

In the case of LCD displays, the main advantage lies in the low manufacturing cost, with dozens of players in the market offering competitive pricing and a high production volume. Some brands have taken advantage of this feature to prioritize certain features - such as a higher refresh rate - instead of adopting an OLED panel, such as the Xiaomi Mi 10T.

This project involves yet another Arduino-compatible display which can be used as an output to display any information in the form of graphics, text or animations. Since this is a 1.3" 240x240 IPS (In-Plane Switching) TFT display module, it does offer a high-resolution colour display with fine graphics, and that is one of the things which I really enjoy about this display. It is also very easy to program, as it runs on the STT789 display, which is helpful to know, as the Adafruit ST7789 library supports this display, and is what we will be using today. The code used below is a fairly complex code at first, which showcases this display"s capabilities and what it can do, in terms of functionality. For the wiring, a 6-pin wiring configuration is used with the SPI interface to the Arduino, which will be shown below. Finally, for this project, here are the components which you will need:1 1.3" 240x240 IPS TFT Display Module

This code may seem slightly intimidating at first, due to its length and much newer functions, but once it is broken down, it isn"t so hard anymore. In the first three lines, we declare libraries for running this display, the graphics used, and for the interface used, which is the SPI interface. In the next three lines, the RST (Reset) and DC (Data/Command) pins are defined, which are connected to A8 (analog pin 8) and A9 (analog pin 9). In the next line, we initialize the Adafruit ST7789 library for use with this display and we follow that by defining the value of pi as a float variable in that next line. We will be using this float variable later on for graphics and calculations needed. Thevoid setupsection is now here where we first start by begining serial communication with a baud rate of 9600 bauds and printing a test message which is "Hello! ST7789 TFT Test!". In regards to the display, we address that our display module is of 240x240 resolution and we set the rotation of our display in the next line. If your display is flipped, removetft.setRotation(2). From there, we print the text "Initialized" as our display is now correctly set up. After that, we count up the seconds from the startup with themillis()function and store it in an unsigned 16-bit integer, namedtime, for use later. We then fill up the TFT screen with a black colour. Since we already started the stopwatch which counts up, we can always reset the stopwatch back to zero by using subtracting thetimefunction with themillis().To end off this section, we set a delay for 500 milliseconds before moving on. This section onwards will only be for the animations, graphics and images displayed on the screen, and we start off by filling the screen with a black background and writing some text with a white colour before a 1-second delay. Proceeding that, we execute a print test which basically is already programmed to print out a set of text in different font colours and sizes. We end this test by setting a delay for 4 seconds. From this point, the rest of the code is responsible for printing out the different graphics, which can be composed of shapes, pixels and text. All the different graphics and its individual code are mentioned at the end of the code so I recommend really going through this program to learn all the commands, which can help you build your own demo code, even with your own personal images being displayed. This project is now done!

This 2.0”LCD display adopts T7789V driver chip and has 320*240 color pixels (RGB565). It uses IPS TFT display and can display 18-bit color(16-bit is basically used). The module performs excellently in displaying color bitmap. Besides, there is an onboard MicroSD card slot for displaying more pictures. There are two connection ways for this module: pin headers and GDI. Only one fpc cable is needed when working with main-cotnrollers with GDI, which greatly reduces the complexity of wiring.

WARNING: BTT does not officially provide MKS TFT hardware support. MKS TFT is maintained by open source contributors and BTT does not bear any risk of MKS TFT hardware using this firmware.

In case your mainboard provides EXP1 and EXP2, you have to connect 2 ribbon cables connecting EXP1 and EXP2 of the mainboard to EXP1 and EXP2 of the TFT. In the Marlin firmware of your mainboard, make sure that ONLY REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER is activated in Configuration.h and that all other controllers are Deactivated (especially CR10_STOCKDISPLAY).

In case you have an "E3" mainboard which provides a single EXP connector, you have to connect 1 ribbon cable connecting EXP of the mainboard to EXP3 of the TFT. In case your TFT does not provide an EXP3 connector but only two 10pin connectors (TFT24 v1.1 for example) you will need a "Y-split" cable with one 10pin connector on one side (for the mainboard) and two 10pin connectors on the other side (for the TFT). In the Marlin firmware of your mainboard, make sure that ONLY CR10_STOCKDISPLAY is activated in Configuration.h and that all other controllers are Deactivated (especially REPRAP_DISCOUNT_FULL_GRAPHIC_SMART_CONTROLLER).

Any binary file for an MKS firmware (e.g. MKS_TFT28_V4.0.27.x.bin) MUST be renamed to MKSTFT*.bin (e.g. MKSTFT28.bin, MKSTFT35.bin etc.) in order it can be recognized and installed by the TFT

A configuration can be uploaded without the need to upload the firmware or the TFT folder again, as long as the firmware and the configuration file are from the same version (see Configuration Update).

Copy the precompiled BIGTREE_TFT*_V*.*.*.bin or your self compiled firmware, plus the TFT* folder of your preferred theme along with config.ini to the root of a blank SD card not greater than 8GB and formatted as FAT32:

Optionally, copy one or more language_*.ini file(s) onto the SD card. Doing so, it will allow you to switch between English and the uploaded language(s) from the Language menu present in the TFT firmware. We recommend to upload the minimum amount of languages to keep the memory usage low. The language_*.ini file can be edited to change the text shown on the TFT:

Place the SD card with BIGTREE_TFT*_V*.*.*.bin, the TFT* folder, config.ini and the optional language_*.ini file(s) into the TFT"s SD card reader and reset your TFT (or optionally - power cycle your printer) to start the update process:

Unless the default hard coded settings have been properly configured (e.g. a self compiled firmware was installed), after an hard reset the TFT typically needs to be reconfigured with the proper config.ini file (see Configuration Update)

When the default hard coded settings are properly configured for a TFT and the TFT"s basic function such as surfing on the menus is working, in case of issues the user can opt to apply only a configuration reset (soft reset) instead of an hard reset.

A BIGTREE_TFT*_V*.*.*.bin file will be generated in the hidden .pio\build\BIGTREE_TFT*_V*_* folder. Follow the update process outlined in the Firmware Update section above to update your TFT to the latest version

TIP: In case there is a problem compiling the TFT firmware try to restart VSC. If this does not help and you are using macOS, delete the packages and platforms folders usually present under the folder /Users/***username***/.platformio/.

In case the TFT needs to be placed with a vertical orientation (e.g. 90°), the firmware needs to be compiled with the portrait mode support and installed following the procedure below:

OctoPrint, ESP3D, Pronterface etc, connected to a TFT"s serial port, can browse files on both the TFT"s and mainboard"s media devices and start a print that will be handled by the host (TFT or mainboard). The following actions and the related triggering G-codes are currently supported by the TFT fw:

OctoPrint, ESP3D, Pronterface etc, connected to a TFT"s or mainboard"s serial port, can host a print (print handled by the host) and optionally can trigger some actions to the TFT sending specific G-codes. The following actions and the related triggering G-codes are currently supported by the TFT fw:

Only on print end or cancel (with triggers print_end or cancel) the TFT Printing menu is finalized (statistics available etc.) and unlocked (the menu can be closed).

With the exception of TFT70, the maximum number of displayable layer count is 999 (there"s no space to display layer number and count if the layer count is above 999)

The most recent version of the standard bigtreetech TFT firmware has built in support for RepRap firmware. The pre-built images have this enabled by default.

The TFT35 E3 V3.0 has 3 cables to connect to the mainboard. Two 10 pin ribbon cables and one 5 pin serial cable. The 2 ribbon cables connect to the EXP1 and the EXP2 connections on both the TFT35 E3 V3.0 and the MKS mainboards.

NOTE: On the MKS mainboards there is an issue that involves at least the MKS GEN_L, MKS SGEN, and MKS SGEN_L models. The EXP1 and EXP2 connections have the socket shell installed wrong way around. The notch that indexes the cable should be facing towards the mainboard. If you get a blank screen on the TFT35 E3 V3.0 touchscreen after connecting the two EXP cables and turning the printer on, turn printer off and disconnect the 10 pin cables from either the touch screen or the mainboard and using small diagonal cutters trim the tab down to be as close to flush as you can get on both cables (and only on one end) and plug them back in with the trimmed tab now facing the mainboard.

In case filament data is not present in the G-code, the filament length data is calculated during print. Length is calculated regardless of using the TFT USB, TFT SD or the onboard media. Calculations are done in both absolute or relative extrusion mode. Filament data takes into account the flow rate also but with a caveat. It has to be the same flow rate during the entire time of the printing, because the end result is calculated based on the flow rate at the time the print has finished. If flow rate changes during the print the results will not be accurate anymore.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey