ito lcd panel factory

Important technical improvements of LCD, such as LED backlighting and wide viewing Angle, are directly related to LCD. And account for an LCD display 80% of the cost of the LCD panel, enough to show that the LCD panel is the core part of the entire display, the quality of the LCD panel, can be said to directly determine the quality of an LCD display.

The production of civil LCD displays is just an assembly process. The LCD panel, the main control circuit, shell, and other parts of the main assembly, basically will not have too complex technical problems.

Does this mean that LCDS are low-tech products? In fact, it is not. The production and manufacturing process of the LCD panels is very complicated, requiring at least 300 process processes. The whole process needs to be carried out in a dust-free environment and with precise technology.

The general structure of the LCD panel is not very complex, now the structure of the LCD panel is divided into two parts: the LCD panel and the backlight system.

Due to the LCD does not shine, so you need to use another light source to illuminate, the function of the backlight system is to this, but currently used CCFL lamp or LED backlight, don’t have the characteristics of the surface light source, so you need to guide plate, spreadsheet components, such as linear or point sources of light evenly across the surface, in order to make the entire LCD panel on the differences of luminous intensity is the same, but it is very difficult, to achieve the ideal state can be to try to reduce brightness non-uniformity, the backlight system has a lot to the test of design and workmanship.

In addition, there is a driving IC and printed circuit board beside the LCD panel, which is mainly used to control the rotation of LCD molecules in the LCD panel and the transmission of display signals. The LCD plate is thin and translucent without electricity. It is roughly shaped like a sandwich, with an LCD sandwiched between a layer of TFT glass and a layer of colored filters.

LCD with light refraction properties of solid crystals, with fluid flow characteristics at the same time, under the drive of the electrode, can be arranged in a way that, in accordance with the master want to control the strength of the light through, and then on the color filter, through the red, green, blue three colors of each pixel toning, eventually get the full-screen image.

According to the functional division, the LCD panel can be divided into the LCD panel and the backlight system. However, to produce an LCD panel, it needs to go through three complicated processes, namely, the manufacturing process of the front segment Array,the manufacturing process of the middle segment Cell, and the assembly of the rear segment module. Today we will be here, for you in detail to introduce the production of the LCD panel manufacturing process.

The manufacturing process of the LCD panel Array is mainly composed of four parts: film, yellow light, etch and peel film. If we just look at it in this way, many netizens do not understand the specific meaning of these four steps and why they do so.

First of all, the motion and arrangement of LCD molecules need electrons to drive them. Therefore, on the TFT glass, the carrier of LCD, there must be conductive parts to control the motion of LCD. In this case, we use ITO (Indium Tin Oxide) to do this.ITO is transparent and also acts as a thin-film conductive crystal so that it doesn’t block the backlight.

The different arrangement of LCD molecules and the rapid motion change can ensure that each pixel displays the corresponding color accurately and the image changes accurately and quickly, which requires the precision of LCD molecule control.ITO film needs special treatment, just like printing the circuit on the PCB board, drawing the conductive circuit on the whole LCD board.

First, the ITO film layer needs to be deposited on the TFT glass, so that there is a smooth and uniform ITO film on the whole TFT glass. Then, using ionized water, the ITO glass is cleaned and ready for the next step.

Next, a photoresist is applied to the glass on which ITO film is deposited, and a uniform photoresist layer is formed on the ITO glass. After baking for a period of time, the solvent of the photoresist was partially volatilized to increase the adhesion of the photoresist material to the ITO glass.

Then etch off the ITO film without photoresist covering with appropriate acid etching solution, and only retain the ITO film under the photoresist. ITO glass is conductive glass (In2O3 and SnO2). The ITO film not covered by photoresist is easy to react with acid, while the ITO film covered by photoresist can be retained to obtain the corresponding wire electrode.

Stripping: High concentration of alkali solution (NaOH solution) is used as a stripping solution to peel off the remaining photoresist on the glass so that ITO glass can form ITO graphics exactly consistent with the photolithography mask.

This completes the previous Array process. It is not difficult to see from the whole process that ITO film is deposited, photoresist coated, exposed, developed, and etched on TFT glass, and finally, ITO electrode pattern designed in the early stage is formed on TFT glass to control the movement of LCD molecules on the glass. The general steps of the whole production process are not complicated, but the technical details and precautions are very complicated, so we will not introduce them here. Interested friends can consult relevant materials by themselves.

The glass that the LCD board uses makes a craft also very exquisite. (The manufacturing process flow of the LCD display screen)At present, the world’s largest LCD panel glass, mainly by the United States Corning, Japan Asahi glass manufacturers, located in the upstream of the production of LCD panel, these manufacturers have mastered the glass production technology patents. A few months ago, the earthquake caused a corning glass furnace shutdown incident, which has caused a certain impact on the LCD panel industry, you can see its position in the industry.

As mentioned earlier, the LCD panel is structured like a sandwich, with an LCD sandwiched between the lower TFT glass and the upper color filter. The terminal Cell process in LCD panel manufacturing involves the TFT glass being glued to the top and bottom of a colored filter, but this is not a simple bonding process that requires a lot of technical detail.

As you can see from the figure above, the glass is divided into 6 pieces of the same size. In other words, the LCD made from this glass is finally cut into 6 pieces, and the size of each piece is the final size. When the glass is cast, the specifications and sizes of each glass have been designed in advance.

Then, the organic polymer directional material is coated on the surface of the glass, that is, a uniform directional layer is applied to the appropriate position of ITO glass by the method of selective coating. Meanwhile, the directional layer is cured.

Directional friction:Flannelette material is used to rub the surface of the layer in a specific direction so that the LCD molecules can be arranged along the friction direction of the aligned layer in the future to ensure the consistency of the arrangement of LCD molecules. After the alignment friction, there will be some contaminants such as flannelette thread, which need to be washed away through a special cleaning process.

After the TFT glass substrate is cleaned, a sealant coating is applied to allow the TFT glass substrate to be bonded to the color filter and to prevent LCD outflow.

Finally, the conductive adhesive is applied to the frame in the bonding direction of the glass of the color filter to ensure that external electrons can flow into the LCD layer. Then, according to the bonding mark on the TFT glass substrate and the color filter, two pieces of glass are bonded together, and the bonding material is solidified at high temperatures to make the upper and lower glasses fit statically.

Color filters are very important components of LCD panels. Manufacturers of color filters, like glass substrate manufacturers, are upstream of LCD panel manufacturers. Their oversupply or undersupply can directly affect the production schedule of LCD panels and indirectly affect the end market.

As can be seen from the above figure, each LCD panel is left with two edges after cutting. What is it used for? You can find the answer in the later module process

Finally, a polarizer is placed on both sides of each LCD substrate, with the horizontal polarizer facing outwards and the vertical polarizer facing inwards.

When making LCD panel, must up and down each use one, and presents the alternating direction, when has the electric field and does not have the electric field, causes the light to produce the phase difference and to present the light and dark state, uses in the display subtitle or the pattern.

The rear Module manufacturing process is mainly the integration of the drive IC pressing of the LCD substrate and the printed circuit board. This part can transmit the display signal received from the main control circuit to the drive IC to drive the LCD molecules to rotate and display the image. In addition, the backlight part will be integrated with the LCD substrate at this stage, and the complete LCD panel is completed.

Firstly, the heteroconductive adhesive is pressed on the two edges, which allows external electrons to enter the LCD substrate layer and acts as a bridge for electronic transmission

Next is the drive IC press. The main function of the drive IC is to output the required voltage to each pixel and control the degree of torsion of the LCD molecules. The drive IC is divided into two types. The source drive IC located in the X-axis is responsible for the input of data. It is characterized by high frequency and has an image function. The gate drive IC located in the Y-axis is responsible for the degree and speed of torsion of LCD molecules, which directly affects the response time of the LCD display. However, there are already many LCD panels that only have driving IC in the X-axis direction, perhaps because the Y-axis drive IC function has been integrated and simplified.

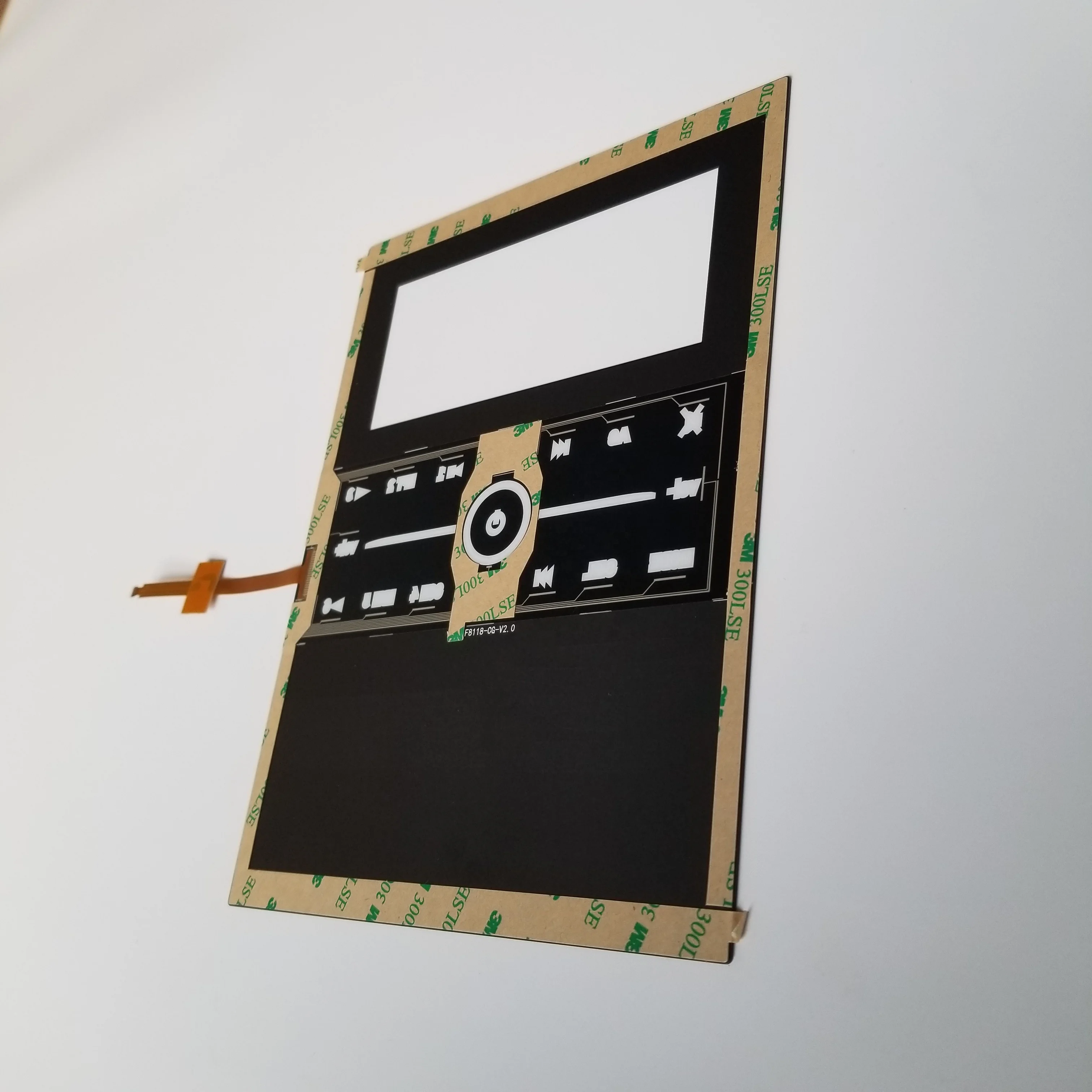

The press of the flexible circuit board can transmit data signals and act as the bridge between the external printed circuit and LCD. It can be bent and thus becomes a flexible or flexible circuit board

The manufacturing process of the LCD substrate still has a lot of details and matters needing attention, for example, rinse with clean, dry, dry, dry, ultrasonic cleaning, exposure, development and so on and so on, all have very strict technical details and requirements, so as to produce qualified eyes panel, interested friends can consult relevant technical information by a search engine.

LCD (LC) is a kind of LCD, which has the properties of light transmission and refraction of solid Crystal, as well as the flow property of Liquid. It is because of this property that it will be applied to the display field.

However, LCD does not emit light autonomously, so the display equipment using LCD as the display medium needs to be equipped with another backlight system.

First, a backplate is needed as the carrier of the light source. The common light source for LCD display equipment is CCFL cold cathode backlight, but it has started to switch to an LED backlight, but either one needs a backplate as the carrier.

CCFL backlight has been with LCD for a long time. Compared with LED backlight, CCFL backlight has many defects. However, it has gradually evolved to save 50% of the lamp and enhance the transmittance of the LCD panel, so as to achieve the purpose of energy-saving.

With the rapid development of LED in the field of lighting, the cost has been greatly reduced.LCD panels have also started to use LED as the backlight on a large scale. Currently, in order to control costs, an LED backlight is placed on the side rather than on the backplate, which can reduce the number of LED grains.

At the top of the diffusion plate, there will be 3~4 diffuser pieces, constantly uniform light to the whole surface, improve the uniformity of light, which is directly related to the LCD panel display effect. Professional LCD in order to better control the brightness uniformity of the screen, panel procurement, the later backlight control circuit, will make great efforts to ensure the quality of the panel.

Since the LCD substrate and the backlight system are not fixed by bonding, a metal or rubber frame is needed to be added to the outer layer to fix the LCD substrate and the backlight system.

After the period of the Module, the process is completed in LCM (LCDModule) factory, the core of this part of the basic does not involve the use of LCD manufacturing technology, mainly is some assembly work, so some machine panel factories such as chi mei, Korea department such as Samsung panel factory, all set with LCM factories in mainland China, Duan Mo group after the LCD panel assembly, so that we can convenient mainland area each big monitor procurement contract with LCD TV manufacturers, can reduce the human in the whole manufacturing and transportation costs.

However, neither Taiwan nor Korea has any intention to set up factories in mainland China for the LCD panel front and middle manufacturing process involving core technologies. Therefore, there is still a long way to go for China to have its own LCD panel industry.

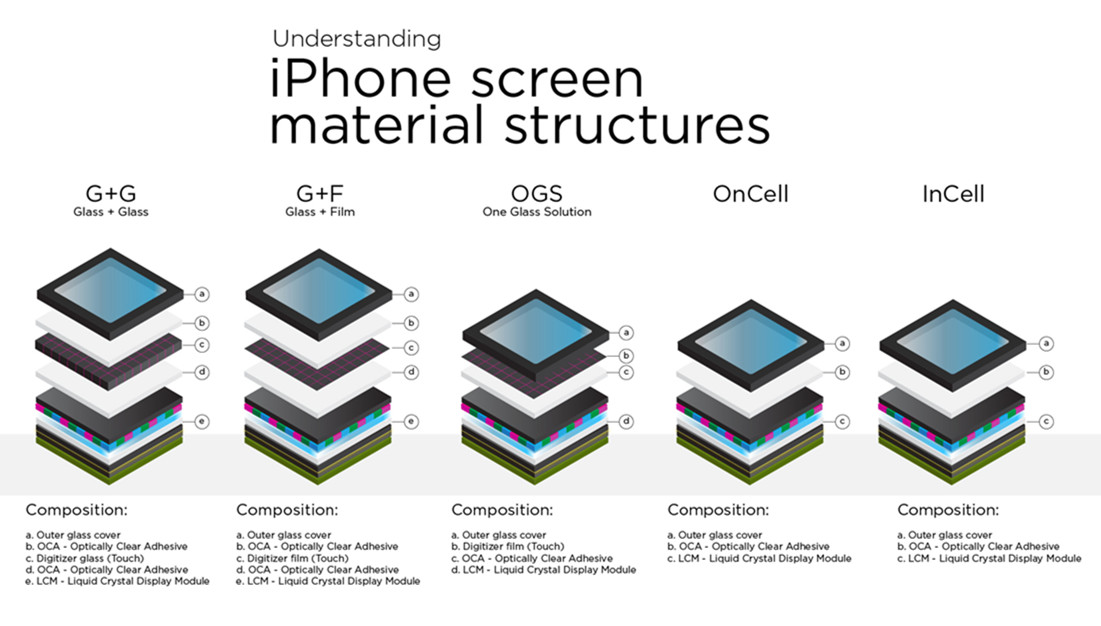

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"TCL"s Panel Manufacturer CSOT Commences Production of High Generation Panel Modules". www.businesswire.com. June 14, 2018. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Many LCD technologies, such as monochrome character, dot matrix and segment displays, make use of ITO glass. Even though ITO glass has been in existence for some time, it is still an important aspect in LCD designs and will be covered in the article below.

The article about ITO glass was written by Barbara Dutra, an exchange engineering student from Brazil, who is currently an intern at Focus Display Solutions. Her current job responsibilities include ISO certification, Test and quality insurance of inbound LCD displays and writing technical articles.

The Indium tin oxide is a material used in modern devices that manipulates ambient light. ITO is a good material, because it has a good response time to conduct electricity and an appropriate transparency for the emission of light.

It is also used in flat panel TVs where each pixel is turned ON or OFF by a pair of transparent electrodes ITO. Touch screen displays are the latest innovations using that material.

The first touchscreen devices were sold with a pen and were manufactured with two layers of ITO glass separated by a small gap. When the resistive screens were touched with a pen, the two layers came into contact, creating a short circuit and allowing a current to pass and be detected by the device.

New devices, implementing newer technology, use the finger to allow the short circuit that identifies the position without the need of a pen. The touch in the screen changes its capacitance at that location and this change is perceived by a single layer of ITO.

The ITO glass is a thin transparent film similar to common glass, but unlike glass, it is a conductor of electricity because it is a kind of transparent conductive oxide (TCO). So it has the property of reflecting electromagnetic radiation in the infrared region (spectrum) and having a low electrical resistivity.

The ITO is the best TCO because it is a good combination of transparency and conductivity. Because of its transparency, ITO glass does not absorb light photons. Absorption occurs when the photon energy corresponds to what is necessary to let the electron in an excited state.

To produce the thin films of ITO glass, it is common to use sputtering techniques with radio frequency assisted by constant magnetic field (RF magnetron sputtering). The sputtering technique involves the transport of molecules or atoms ejected from a source (also called the target) to a substrate.

The ITO glass is an expensive material because of the indium mineral, but this is not the biggest problem. The biggest challenge is the shortage expected to take place in a few years because indium is a rare mineral.

This is bad news because the market of touch screen devices is in an expansion mode and every day the demand increases since bigger and bigger screens are created using a larger amount of ITO.

Some hypotheses are the cadmium oxide, silver nanowires and graphene (carbon nanomaterial). The first is almost as transparent as ITO glass and has a greater capacity of conduct electricity, but it is very unstable and deteriorates quickly (half-life).

One solution to this problem is to apply 20% of ITO in the cadmium oxide just to create a film of protection on the material. Another problem, an environmental one, is that this oxide is more toxic and demands care in the manipulation and disposal of waste. This could be a future environmental problem.

Silver is very similar to high quality ITO, but it is quite flexible. Unfortunately silver nanowires are ten times more expensive to produce than the already expensive ITO and cheaper metals seem to not work.

The graphene can be used for touch screen displays because of the characteristics but is an expensive technology today. In the future the price between ITO glass and carbon nanotubes will be equivalent because of the lack of indium and carbon segment growth cheapening their cost. So, the graphene looks a promising option.

But that does not rule out this option because the processing power is in expansion. Anyway these free indium techniques do not solve a fundamental problem: with or without touch, the electrodes that provide power to the pixels on the LCD screen depend on the ITO glass. This will be solved only with the development of new materials that emulate the highly desirable ability of the ITO glass to combine transparency and conductivity.

It is safe to say that the cost of LCD displays does not look to be decreasing any time soon, if at all. Part of the reason for higher cost displays is not only the potential cost increase due to an ITO shortage. But a labor shortage that is taking place in many LCD manufacturing locations.

With the development of science and technology, LCD screens have become a go-to product for many because they emit no radiation, have large display information, and offer long service life.

ITO glass input: The appropriate ITO glass is selected for the basket, which is dependent on the requirements of the product in question. It is vital that the specification and model of the ITO glass meet the requirements of the product. The ITO layer must be inserted into the basket facing upwards.

Glass cleaning and drying: ITO glass will be washed with cleaning agents and deionized water (DI water). Any impurities and oil stains on the ITO surface will be washed by physical or chemical methods, with the water then removed and the product dried in preparation for the next stage of the process.

Photoresist coating: An even layer of photoresist will be applied to the conductive layer of ITO glass, and the photoresist-coated glass will be pretreated at a certain temperature.

Etching: The ITO film without photoresist is etched away with an acid etching solution, so as to obtain the ITO electrode pattern required. Note: ITO glass is conductive glass (In203 and Sn02), which easily reacts with acid. This is used to etch away excess ITO, so as to obtain the corresponding pull electrode.

Film removal: A high concentration of lye (Naoh solution) is used as a film removal solution to peel off the remaining photoresist on the glass, so as to form ITO graphics that exactly match the photoresist mask on ITO glass.

There are 2 automatic production lines in Panox Display factory, has a capacity of 300K pcs every months. Main OEM products include 1.7icnh, 2.4 inch,2.8 inch, 3.2inch,4.3 inch,4.7inch, 5.0 inch,5.5 inch ,6.0 inch LCD and other sizes, most of them applied in Mobile displays, such as Moto G5,LG ..

Many products demand a custom LCD to meet application specific display requirements, electrical specifications, or mechanical dimensions. For over 10 years Panox Display has specialized in designing and producing custom LCDs and can quickly help you to create the ideal display for your product. Please click here to send your request designing a custom LCD panel.

JiaXing YiFei Photoelectric Technology Co., Ltd. is located in Xiuzhou District, Jiaxing City, Zhejiang Province, with beautiful scenery. It is a professional company engaged in design and manufacture of capacitive touch panel screen module(CTPM), capacitive touch panel (CTP), liquid crystal display (LCD) and drive control board (BOARD).It"s products are mainly used in industrial control, medical equipment control, car navigation, navigation and aviation equipment, Internet of Things control, UnionPay POS, smart home and other industries. The company has comprehensive capacitive touch module design ability. Since it"s opening, the company has been constantly exploring, improving and maintaining the domestic market, and at the same time actively expanding overseas markets, committed to serving global customers!

YUNLEA is is a leading designer and manufacturer of Capacitive Touch Panel, And we have rich experiences in medical & industrial & home automation& products supply.

In this study, indium-tin-oxide (ITO) nanoparticles were simply recovered from the thin film transistor-liquid crystal display (TFT-LCD) panel scraps by means of lift-off method. This can be done by dissolving color filter (CF) layer which is located between ITO layer and glass substrate. In this way the ITO layer was easily lifted off the glass substrate of the panel scrap without panel crushing. Over 90% of the ITO on the TFT-LCD panel was recovered by using this method. After separating, the ITO was obtained as particle form and their characteristics were investigated. The recovered product appeared as aggregates of particles less than 100 nm in size. The weight ratio of In/Sn is very close to 91/9. XRD analysis showed that the ITO nanoparticles have well crystallized structures with (222) preferred orientation even after recovery. The method described in this paper could be applied to the industrial recovery business for large size LCD scraps from TV easily without crushing the glass substrate.

Thin film transistor-liquid crystal display (TFT-LCD) has been used as a most popular flat panel display. As the TFT-LCD market grows, significant amount of rare material of indium (In) has been continuously consumed in the display manufacturing industry. Indium has been widely used for transparent conductive oxides (TCO) in the form of indium tin oxide (ITO), because it has unique high optical transparency and electrical conductivity. The In resource is quite limited, e.g., the world’s reserve is merely 16,000 tons while the current annual consumption is about 1400 tons [1]. Consequently, global In resources are being exhausted due to their fast consumption rate in information displays, solar cells and lighting [2,3]. Therefore, recycling of indium has become a very important issue these days. A lot of research works aimed at the reuse of In materials has been performed and, as an alternative, the recycling of In from old ITO targets has been studied [4]. However, only a few works aimed at the extraction of In from TFT-LCD panel scraps has been performed. Moreover, we could not find any result on recovery of ITO with the optimal composition ratio of In/Sn as 91/9, which is the characteristics composition of the TCO. Several works reported that In can be recovered by crushing TFT-LCD panel scraps followed by selective extraction. Acquisition of ITO from the TFT-LCD scrap with the optimal ratio is very valuable for cost saving by reducing the number of steps in the recovery process. In this study, a new recycling technology was developed to recover ITO nanoparticles from TFT-LCD scraps. It is called lift-off method because ITO layer is simply lifted off the glass substrate of panel scraps by dissolving color filter (CF) layer which is located between them as in Figure 1. Characteristics such as particle size, thermal property, crystal structure, composition ratio, and purity of the recovered ITO product were investigated.

Lift-off method for recovering indium-tin-oxide (ITO) as nanoparticles from glass substrate of thin film transistor-liquid crystal display (TFT-LCD) scraps.

An alkaline solution was received from D. Company (Seoul, Korea) and used as a dissolving agent for the color filter. The solution consists of mainly KOH and NaOH and its pH is about 13.4. Polycarbonate (PC) membrane (Iso pore) having 0.4 μm pore diameter was purchased from Milllipore and used as a filter. Methylene Chloride (extra pure grade, Daejung Chemical and Metals, Korea) was used to dissolve the PC membrane. Deionized (DI) water was used to wash out the sample after each step. ITO was taken from a 7 inch size TFT-LCD panel scraps. Disassembly of the TFT-LCDs was done according to previously published methods [5]. First, the upper and lower portions were separated by cutting the edge of the TFT-LCD panel scraps. After cutting, the two plates were easily separated by removing residual liquid crystal with acetone. The upper plate was dipped into the alkaline solution at 80 °C for 30 min. Then the ITO was separated from the glass substrate automatically and remained in the solution after taking the glass substrate out of the solution. The ITO precipitate in the solution was filtered and washed several times with D.I. water. Filter cake was dried in a convection oven at 60 °C for 1 h. Then the thermal behavior of the filter cake was analyzed by thermogravimetric analysis (TGA) and differential thermal analysis (DTA) were performed by using thermogravimetry/differential thermal analyzer (TG/DTA: Seiko Exstar 6000, Seico Inst., Japan). In this way, the heat-treatment temperature to burn out the organic components was determined. The particle size, crystal structure, composition ratio, and purity of the ITO was analyzed by means of high-resolution transmission electron microscope (HRTEM: 300 kV, JEOL, Japan), field-emission scanning microscope (FESEM: JSM-7000F, JEOL, Japan), X-ray diffractometer (XRD: Rigaku Rotaflex D/MAX System) with monochromatic Cu target (λ = 0.1541 nm), inductively coupled plasma (ICP, ICP Optima 43DV, Perkin Elmer, Waltham, MA, USA), X-ray photoelectron spectroscopy (XPS: VG Microtech ESCA2000), using Al Kα radiation as an exciting source. All binding energies (BE) were referenced to the C 1s peak at 284.6 eV.

Figure 2a shows the cross-sectional SEM image of 7 inch LCD upper plate taken from a car navigator. The thickness of ITO was observed as 170 nm. Figure 2b shows the simple recovery scheme. The upper plate was immersed into the alkaline solution. After 30 min, the colorless alkaline solution was changed to blue color. That means some parts of RGB pigments were dissolved. This solution was filtered with the polycarbonate (PC) membrane (pore size 0.4 µm).

The filter cake appeared as two parts, film shape part and granular part as in Figure 3a. In the part A, many of irregular film pieces were found. According to the energy dispersive spectrometer (EDS) analysis as shown in Figure 3b its major component was indium. Therefore we estimated that these pieces came from ITO. The granular part B was quite different from the part A. The EDS analysis in Figure 3c shows the elemental components of the aggregate part are carbon, nitrogen, oxygen, copper and magnesium etc. indicating this part came from color filter.

The specific analysis of ITO with EDS is very difficult because energy levels of indium and tin are too close to differentiate each other. Therefore, we studied the composition via XPS measurement. The XPS spectra of filter cake are shown in Figure 4. As shown in Figure 4a the peaks located at 444.6, and 452.2 eV corresponding to the In 3d5/2 and In 3d3/2 state, respectively. These are related to In3+ bonding state in the In2O3 [6,7,8,9,10]. Figure 4b shows that Sn 3d5/2 and Sn 3d3/2 peaks located at 486.6, 495.2 eV respectively. These binding energies indicate that the Sn is in the Sn4+ bonding state from SnO2 [7,10]. According to the XPS analysis, the binding energy of filter cake, part A, was in good agreement with a typical ITO. Therefore, it is concluded that the recovered sample was mostly consisted of ITO.

Most of the filter cake was collected by dissolving the filter with the filter cake with methylene chloride. After decanting the methylene chloride away, the residue was washed with same solvent several times. Thermal behavior of the residue was performed by using TG/DTA. As shown in Figure 5a, TG/DTA curves were obtained in the range of ambient temperature to 1000 °C at a heating rate of 10 °C·min−1 in air at atmospheric pressure. The first weight loss was observed in temperature range, i.e., between 200 °C and 400 °C, and DTA curve shows the exothermic reaction showing a peak at around 400 °C. This weight loss maybe due to decomposition of CF pigments in the residue. Composition of the CF materials really depends on the producing company but most of them are based on anthraquinone (red) and phtalocyanine (green or blue) [11]. These materials show the weight loss and exothermic reaction at temperatures lower than 600 °C [12,13,14]. These results indicate that thermal decomposition of the CF pigments could occur at lower than 600 °C. The inset in Figure 5a shows the yellow ITO powder obtained after heat treatment at 600 °C for 1 h in air. The color was similar to that of commercial ITO powder. The morphology of recovered ITO was observed by using HRTEM. The sizes of recovered ITO particles were less than 100 nm in diameter and appeared as aggregate as shown in Figure 5b.

Thermal behavior (a) and high-resolution transmission electron microscope (HRTEM) image (b) of the recovered ITO powder from TFT-LCD panel after heat treatment at 600 °C.

Figure 6 shows the X-ray diffraction pattern of the recovered ITO powder after heat-treatment at 600 °C. This pattern indicates that our sample has quite similar structure compared to a typical ITO crystal structure. The most intensive diffraction peak appeared at 30.5° and other peaks were at 35.5°, 50.9° and 60.7°. This pattern matches well with the diffraction pattern for the (222), (400), (440) and (622) orientations of cubic crystalline ITO [15,16]. Thus, the ITO particles after heat-treatment at 600 °C are well crystallized as cubic structure. However, the splitting of diffraction peak appeared at 30° indicates that the recovered ITO consists of two different layers. According to the reported results [17,18,19], splitting of XRD peak in ITO films was attributed to existence of two differently strained layers, i.e., amorphous and crystalline layer. The diffraction pattern of the recovered material was similar to that of pure ITO. It is supposed that most In atoms are uniformly substituted to Sn atoms in the lattice [20].

We have successfully recovered ITO in the form of nanoparticle from TFT-LCD panel scraps by using a simple lift-off method. This lift-off approach provided us a useful recovery method with high yield of 90%. ITO was easily separated as nanoparticles from glass substrate of TFT-LCD scarp. The size of the ITO nanoparticle was less than 100 nm, and appeared as aggregates. The recovered ITO was well crystallized to a (222) preferred orientation, and the composition ratio of In to Sn of about 91 to 9. The lift-off method described in this paper could be easily applied to the large scale recovery business dealing large size LCD panels from TV and other displays.

1. Global and china ITO sputtering targets industry research report 2013–2016. [(accessed on 26 November 2014)]. Available online: http://www.researchmoz.us/global-and-china-ito-sputtering-targets-industry-report-2013-2016-report.html

4. Yu J.-K., Kang S.-G., Jung K.-C., Han J.-S., Kim D.-H. Fabrication of nano-sized ITO powder from waste ITO target by spray pyrolysis process. Mater. Trans.2007;48:249–257. doi: 10.2320/matertrans.48.249. [CrossRef]

5. Hong S.-J., Kim M.-S., Kim J.-W., Shin M. Characteristics of indium-tin-oxide (ITO) glass re-used from old TFT-LCD panel. Mater. Trans.2012;53:968–972. doi: 10.2320/matertrans.MBW201122. [CrossRef]

9. Pammi S., Chanda A., Seong N.-J., Yoon S.-G. Growth of high-quality ITO thin films at low temperature by tuning the oxygen flow rate using the nano-cluster deposition (NCD) technique. Chem. Phys. Lett.2010;490:234–237. doi: 10.1016/j.cplett.2010.03.035. [CrossRef]

10. Choi D., Kim Y.S., Son Y. Recovery of indium tin oxide (ITO) and glass plate from discarded TFT-LCD panels using an electrochemical method and acid treatment. RSC Adv.2014;4:50975–50980. doi: 10.1039/C4RA11085D. [CrossRef]

11. Kopacek B. ReLCD recycling and re-use of LCD panels; Proceedings of the 19th Waste Management Conference of the IWMSA (WasteCon2008); Durban, South Africa. 6–10 October 2008; pp. 6–10.

20. Nadaud N., Lequeux N., Nanot M., Jove J., Roisnel T. Structural studies of tin-doped indium oxide (ITO) and In4Sn3O12. J. Solid State Chem.1998;135:140–148. doi: 10.1006/jssc.1997.7613. [CrossRef]

With the development of science and technology, LCD screens have become a go-to product for many because they emit no radiation, have large display information, and offer long service life.

ITO glass input: The appropriate ITO glass is selected for the basket, which is dependent on the requirements of the product in question. It is vital that the specification and model of the ITO glass meet the requirements of the product. The ITO layer must be inserted into the basket facing upwards.

Glass cleaning and drying: ITO glass will be washed with cleaning agents and deionized water (DI water). Any impurities and oil stains on the ITO surface will be washed by physical or chemical methods, with the water then removed and the product dried in preparation for the next stage of the process.

Photoresist coating: An even layer of photoresist will be applied to the conductive layer of ITO glass, and the photoresist-coated glass will be pretreated at a certain temperature.

Etching: The ITO film without photoresist is etched away with an acid etching solution, so as to obtain the ITO electrode pattern required. Note: ITO glass is conductive glass (In203 and Sn02), which easily reacts with acid. This is used to etch away excess ITO, so as to obtain the corresponding pull electrode.

Film removal: A high concentration of lye (Naoh solution) is used as a film removal solution to peel off the remaining photoresist on the glass, so as to form ITO graphics that exactly match the photoresist mask on ITO glass.

There are 2 automatic production lines in Panox Display factory, has a capacity of 300K pcs every months. Main OEM products include 1.7icnh, 2.4 inch,2.8 inch, 3.2inch,4.3 inch,4.7inch, 5.0 inch,5.5 inch ,6.0 inch LCD and other sizes, most of them applied in Mobile displays, such as Moto G5,LG ..

Many products demand a custom LCD to meet application specific display requirements, electrical specifications, or mechanical dimensions. For over 10 years Panox Display has specialized in designing and producing custom LCDs and can quickly help you to create the ideal display for your product. Please click here to send your request designing a custom LCD panel.

In both LCD and OLED displays, producing these cells – which are highly complex – is by far the most difficult element of the production process. Indeed, the complexity of these cells, combined with the levels of investment needed to achieve expertise in their production, explains why there are less than 30 companies in the whole world that can produce them. China, for instance, has invested more than 300 billion yuan (approximately $45 billion USD) in just one of these companies – BOE – over the past 14 years.

Panox Display has been involved in the display industry for many years and has built strong and long-term partner relationships with many of the biggest OLED and LCD panel manufacturers. As a result, we are able to offer our clients guaranteed access to display products from the biggest manufacturers.

LG Display was, until 2021, the No. 1 display panel manufacturer in the world. Owned by LG Group and headquartered in Seoul, South Korea, it has R&D, production, and trade institutions in China, Japan, South Korea, the United States, and Europe.

Founded in 2001, AUO – or AU Optronics – is the world’s leading TFT-LCD panel manufacturer (with a 16% market share) that designs, develops, and manufactures the world’s top three liquid crystal displays. With panels ranging from as small as 1.5 inches to 46 inches, it boasts one of the world"s few large-, medium -and small-sized product lines.

AUO offers advanced display integration solutions with innovative technologies, including 4K2K ultra-high resolution, 3D, ultra-thin, narrow bezel, transparent display, LTPS, OLED, and touch solutions. AOU has the most complete generation production line, ranging from 3.5G to 8.5G, offering panel products for a variety of LCD applications in a range of sizes, from as small as 1.2 inches to 71 inches.

Now Sharp is still top 10 TV brands all over the world. Just like BOE, Sharp produce LCDs in all kinds of size. Including small LCD (3.5 inch~9.1 inch), medium LCD (10.1 ~27 inch), large LCD (31.5~110 inch). Sharp LCD has been used on Iphone series for a long time.

Beside those current LCDs, the industrial LCD of Sharp is also excellent and widely used in public facilities, factories, and vehicles. The Sharp industrial LCD, just means solid, high brightness, super long working time, highest stability.

Since its establishment, Truly Semiconductors has focused on researching, developing, and manufacturing liquid crystal flat panel displays. Now, after twenty years of development, it is the biggest small- and medium-sized flat panel display manufacturer in China.

Truly’s factory in Shanwei City is enormous, covering an area of 1 million square meters, with a net housing area of more than 100,000 square meters. It includes five LCD production lines, one OLED production line, three touch screen production lines, and several COG, LCM, MDS, CCM, TAB, and SMT production lines.

Its world-class production lines produce LCD displays, liquid crystal display modules (LCMs), OLED displays, resistive and capacitive touch screens (touch panels), micro camera modules (CCMs), and GPS receiving modules, with such products widely used in the smartphone, automobile, and medical industries. The LCD products it offers include TFT, TN, Color TN with Black Mark (TN type LCD display for onboard machines), STN, FSTN, 65K color, and 262K color or above CSTN, COG, COF, and TAB modules.

In its early days, Innolux attached great importance to researching and developing new products. Mobile phones, portable and mounted DVD players, digital cameras, games consoles, PDA LCDs, and other star products were put into mass production and quickly captured the market, winning the company considerable market share.

Looking forward to the future, the group of photoelectric will continue to deep LCD display field, is committed to the development of plane display core technology, make good use of global operations mechanism and depth of division of labor, promise customers high-quality products and services, become the world"s top display system suppliers, in 2006 in the global mobile phone color display market leader, become "Foxconn technology" future sustained rapid growth of the engine.

Founded in June 1998, Hannstar specializes in producing thin-film transistor liquid crystal display panels, mainly for use in monitors, notebook displays and televisions. It was the first company in Taiwan to adopt the world’s top ultra-wide perspective technology (AS-IPS).

The company has three LCD factories and one LCM factory. It has acquired state-of-the-art TFT-LCD manufacturing technology, which enables it to achieve the highest efficiency in the mass production of thin-film transistor liquid crystal display production technology. Its customers include many of the biggest and most well-known electronics companies and computer manufacturers in Taiwan and overseas.

TCL CSOT – short for TCL China Star Optoelectronics Technology (TCL CSOT) – was founded in 2009 and is an innovative technology enterprise that focuses on the production of semiconductor displays. As one of the global leaders in semiconductor display market, it has bases in Shenzhen, Wuhan, Huizhou, Suzhou, Guangzhou, and India, with nine panel production lines and five large modules bases.

TCL CSOT actively produces Mini LED, Micro LED, flexible OLED, printing OLED, and other new display technologies. Its product range is vast – including large, medium, and small panels and touch modules, electronic whiteboards, splicing walls, automotive displays, gaming monitors, and other high-end display application fields – which has enabled it to become a leading player in the global panel industry.

In the first quarter of 2022, TCL CSOT’s TV panels ranked second in the market, 55 inches, 65 " and 75 inches second, 8K, 120Hz first, the first, interactive whiteboard and digital sign plate; LTPS flat panel, the second, LTPS and flexible OLED fourth.

EDO (also known as EverDisplay Optonics) was founded in October 2012 and focuses on the production of small- and medium-sized high-resolution AMOLED semiconductor display panels.

Tianma Microelectronics was founded in 1983 and listed on the Shenzhen Stock Exchange in 1995. It is a high-tech enterprise specializing in the production of liquid crystal displays (LCD) and liquid crystal display modules (LCM).

After more than 30 years of development, it has grown into a large publicly listed company integrating LCD research and development, design, production, sales, and servicing. Over the years, it has expanded by investing in the construction of STN-LCD, CSTN-LCD, TFT-LCD and CF production lines and module factories across China (with locations in Shenzhen, Shanghai, Chengdu, Wuhan and Xiamen), as well R&D centers and offices in Europe, Japan, South Korea and the United States.

JDI (Japan Display Inc.) was established on November 15, 2011, as a joint venture between the Industrial Innovation Corporation, Sony, Hitachi, and Toshiba. It is dedicated to the production and development of small-sized displays. It mainly produces small- and medium-sized LCD display panels for use in the automotive, medical, and industrial fields, as well as personal devices including smartphones, tablets, and wearables.

Although Sony’s TVs use display panels from TCL CSOT (VA panel), Samsung. Sony still produces the world’s best micro-OLED display panels. Sony has many micro OLED model such as 0.23 inch, 0.39 inch, 0.5 inch, 0.64 inch, 0.68 inch, 0.71 inch. Panox Display used to test and sell many of them, compare to other micro OLED manufacuturers, Sony`s micro OLEDs are with the best image quality and highest brightness (3000 nits max).

In recent time, China domestic companies like BOE have overtaken LCD manufacturers from Korea and Japan. For the first three quarters of 2020, China LCD companies shipped 97.01 million square meters TFT LCD. And China"s LCD display manufacturers expect to grab 70% global LCD panel shipments very soon.

BOE started LCD manufacturing in 1994, and has grown into the largest LCD manufacturers in the world. Who has the 1st generation 10.5 TFT LCD production line. BOE"s LCD products are widely used in areas like TV, monitor, mobile phone, laptop computer etc.

TianMa Microelectronics is a professional LCD and LCM manufacturer. The company owns generation 4.5 TFT LCD production lines, mainly focuses on making medium to small size LCD product. TianMa works on consult, design and manufacturing of LCD display. Its LCDs are used in medical, instrument, telecommunication and auto industries.

TCL CSOT (TCL China Star Optoelectronics Technology Co., Ltd), established in November, 2009. TCL has six LCD panel production lines commissioned, providing panels and modules for TV and mobile products. The products range from large, small & medium display panel and touch modules.

Established in 1996, Topway is a high-tech enterprise specializing in the design and manufacturing of industrial LCD module. Topway"s TFT LCD displays are known worldwide for their flexible use, reliable quality and reliable support. More than 20 years expertise coupled with longevity of LCD modules make Topway a trustworthy partner for decades. CMRC (market research institution belonged to Statistics China before) named Topway one of the top 10 LCD manufactures in China.

The Company engages in the R&D, manufacturing, and sale of LCD panels. It offers LCD panels for notebook computers, desktop computer monitors, LCD TV sets, vehicle-mounted IPC, consumer electronics products, mobile devices, tablet PCs, desktop PCs, and industrial displays.

JiaXing YiFei Photoelectric Technology Co., Ltd. is located in Xiuzhou District, Jiaxing City, Zhejiang Province, with beautiful scenery. It is a professional company engaged in design and manufacture of capacitive touch panel screen module(CTPM), capacitive touch panel (CTP), liquid crystal display (LCD) and drive control board (BOARD).It"s products are mainly used in industrial control, medical equipment control, car navigation, navigation and aviation equipment, Internet of Things control, UnionPay POS, smart home and other industries. The company has comprehensive capacitive touch module design ability. Since it"s opening, the company has been constantly exploring, improving and maintaining the domestic market, and at the same time actively expanding overseas markets, committed to serving global customers!

YUNLEA is is a leading designer and manufacturer of Capacitive Touch Panel, And we have rich experiences in medical & industrial & home automation& products supply.

Beijing time on October 26th news, China touch screen network news, touch screen technology was born in the 1970s US military. In recent years, iPod music players and later iPhones have become the driving force behind the development of touch screens. With the popularity of these two new applications, the development of touch screens has been greatly promoted. iSuppli has predicted that the global shipment of major touch screen technology will increase from $2.4 billion in 2006 to $4.4 billion in 2012. Faced with such rapid growth, touch screen technology and industry are also rapidly changing and developing. Due to the expansion of production by major manufacturers, the number of ITO film suppliers used in the two main types of touch screen technologies, namely resistive and capacitive touch screens, has been limited, resulting in the shortage of ITO (Indium Tin Oxide) film supply in the touch screen market in the past two years. .

Jiangnan Securities analysis believes that the demand for touch screens increased significantly in 2007, while the growth rate of upstream ITO conductive film production lags behind, resulting in tight supply, and the relevant manufacturers have obtained higher interest rates. Jiangnan Securities analysts believe that after the PDA market bubble in 2002, touch screen material suppliers have not expanded their products for a long time.

According to Displaybank, the global total production of ITO conductive film in 2007 increased by only 13.4% year-on-year. In 2007, touch screen manufacturers were constrained by the upstream ITO conductive film supply restrictions, and capacity expansion was blocked. In 2008, the total output of ITO conductive film increased by 71.2%, especially the leading manufacturer, Nitto Denko, which began to expand production capacity in April 2008.

In 2008, the supply of ITO conductive film shifted from the supply shortage in 2007 to the balance between supply and demand. Hong Jinwei, president of Suzhou Haorui Microelectronics Co., Ltd., said in an interview with China Electronics News that the current supply of ITO film tends to be normal. Now the high-end membrane production technology is mainly in the hands of Japanese manufacturers, such as Nitto Denko, Oike Industrial, etc., other materials such as conductive polymers, carbon nanotubes, ATO (AntimonyTinOxide) and other materials manufacturers in the future. If you can solve the problem of transparency and square resistance well, you have a chance. Similarly, domestic ITO manufacturers have the opportunity to participate in market competition if they can solve these technical problems.

After more than 20 years of development, China"s ITO industry has entered a mature stage, but due to the rapid development of its downstream display industry, the ITO industry continues to have new opportunities and new developments. The ITO film has two trends in the future. One is that the LCD panel manufacturer has completed it by itself, and no need to supply the coating product in the external factory. The other one is the accessory factory. The currently seen application is the touch screen, and the touch screen changes from resistance to capacitance. Coating products offer new development opportunities.

Due to the abundant production capacity of low-end and mid-end ITO products, high-end products such as ITO conductive glass for touch screens are becoming a new hot spot for domestic ITO manufacturers. Domestic manufacturers are striving to improve R&D level and product quality to cope with new business opportunities. The relevant person in charge of Leybold said in an interview with the reporter of China Electronics News that at present, there are many domestic ITO manufacturers. In order to avoid price wars, differentiated competition is the way for enterprises to go. The touch screen is a new application area that Leybold is very concerned about.

The relevant person in charge of CSG said in an interview with the reporter of China Electronics News that CSG is currently a relatively large glass production group in China. In the ITO conductive glass business, CSG is mainly positioned at the high end, mainly STN and touch screen related products. . "At present, the overall application market growth of ITO glass is not obvious. Now it is necessary to find new applications. The touch screen is a new direction." The person in charge said.

They can be divided into two categories, one requires ITO, such as the first three touch screens; the other type does not require ITO, such as the latter screens. Currently, resistive touch screens and capacitive touch screens using ITO materials are the most widely used on the market.

In 2007, Nitto Denko, a high-end film manufacturer of touch screens, invested 1.8 billion yen to increase the production of electrode films for touch screens. It is understood that the company"s electrode film consists of two layers of polyethylene terephthalate (PET) and a transparent electrode ITO layer (indium tin oxide). By turning PET into two layers, durability and input are improved, and input can be achieved with a tap. In April 2008, the company increased its production capacity by three times.

From the current point of view, China"s ITO manufacturers still have a long way to go if they really want to enter the touch screen field. From the history of touch screen development, the touch screen exhibits periodic development characteristics. Objectively speaking, the growth of the current touch screen market has brought a rare opportunity for domestic manufacturers to develop and transform. In the STN/CSTN era, domestically-developed manufacturers, which have been greatly developed in the STN/CSTN era, have been suppressed by TFTs and their business growth has been hindered. Driven by the development of the current touch screen market, many of the original coating technologies have achieved a gorgeous turn, ushered in a new high-speed business growth.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey