passive matrix lcd panel quotation

Alibaba.com offers 536 passive matrix lcd products. About 9% % of these are lcd modules, 1%% are digital signage and displays, and 1%% are mobile phone lcds.

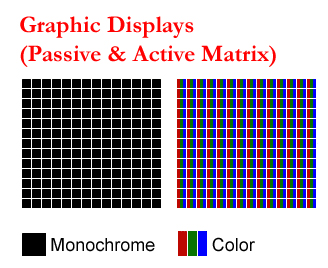

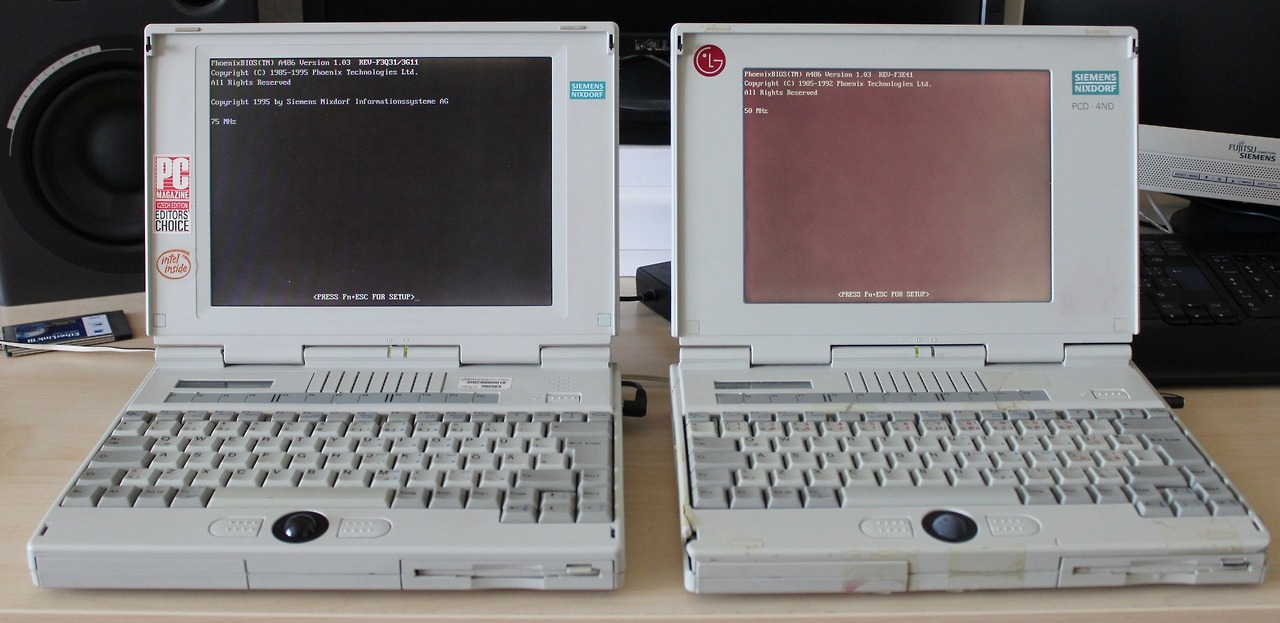

A passive LCD is a low cost option when a display is needed for an application that doesn’t require a high performance display. The difference between a passive-matrix and an active-matrix LCD is that the passive matrix has a grid of horizontal and vertical wires and at the intersection there is an LCD element that makes a single pixel. The active-matrix LCD has a transistor on each pixel, which allows for more contrast, higher resolution and faster response time.

It uses thin film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location.

OLEDs are made from organic light-emitting materials that emit light when electricity is applied. OLED displays are emissive. That is the reason that OLED displays do not require backlight or filtering that are used in LCDs. As a result, OLEDs can be made flexible and transparent while providing the best images and great contrast and view angles.

Similar to LCD displays having two types: Passive Matrix LCD and Active-Matrix LCD, OLED displays also has two types: PMOLED and AMOLED. The difference is in the driving electronics – it can be either Passive Matrix (PM) or Active Matrix (AM).

Similar to passive matrix LCD, a PMOLED display uses a simple control scheme in which you control each row (or line) in the display sequentially (one at a time). PMOLED electronics do not contain a storage capacitor and so the pixels in each line are actually off most of the time. Because of this ,more voltage is needed to make PMOLED brighter. If you have 10 lines, for example, you have to make the one line that is on 10 times as bright (the real number is less than 10, but that’s the general idea).

A.R. Conner and T.J. Scheffer, “Pulse-Height Modulation (PHM) Gray Shading Methods for Passive Matrix LCDs,” Proceedings of Japan Display ’92, pp. 69–72, 1992.

H. Hirai, S. Kondo, A. Murayama, and H. Hatoh, “A New Driving Method for Crosstalk Compensation in Simple-Matrix LCDS,” Proceeding of Japan Display ’92, pp. 499–502, 1992.

Y. Hirai, A. Nakazawa, K. Kawaguchi, H. Motegi, H. Koh, T. Kuwata, Y. Nakagawa, T. Ohbiki, M. Noguchi, and H. Araki, “A Color STN-LCD for Video Display Using Amplitude-Modulation MLS Technology,” SID Digest, pp. 339–342, 1995.

H. Kawakami, Y. Nagae, and E. Kaneko, “Matrix Addressing Technology Of Twisted Nematic Liquid Crystal Display,” Proceedings of Biennial Display Conference, pp. 50–53, 1976.

P. Maltese, “Cross-Modulation and Disuniformity Reduction in the Addressing of Passive Matrix Display,” Proceedings of Euro Display ’84, pp. 15–20, 1984.

H. Mano, S. Nishitani, K. Kondo, J. Taguchi, and H. Kawakami, “An Eight-Gray-Level Drive Method for Fast-Responding STN-LCDs,” SID Digest, pp. 93–96, 1993.

J. Nehring and A.K. Kmetz, “Ultimate Limits for Matrix Addressing of RMS Responding Liquid Crystal Displays,” IEEE Transactions on Electron Devices, Vol. 26, No. 5, pp.795–802, 1979.

A. Nakazawa, K.Tamai, M. Nagai, M. Kitamura, Y. Hirai, S. Matsuoka, and Y. Soda, “Ultra-Low-Power STN-LCDs Using Multiple-Line Addressing for Mobile Telecommunication Applications,” Journal of the SID, Vol. 7, No. 4, pp. 277–280, 1999.

K.G. Panikumar and T.N. Ruckmongathan, “An Addressing Technique for Displaying Restricted Pattern in RMS-Responding LCD’s by Selecting a Few Rows at a Time,” Journal of the SID, Vol. 8, No. 2, pp. 155–162, 2000.

T.N. Ruckmongathan, “A Generalized Addressing Technique for RMS Responding Matrix LCDs,” Proceedings of International Display Research Conference, pp. 80–85, 1988.

T.N. Ruckmongathan, “Novel Addressing Methods For Fast Responding LCDs,” Reports of the Research Laboratory, Asahi Glass Company Ltd., Vol. 43, pp. 65–87, 1993.

S. Smorfa, M. Olivieri, R. Mancuso, and M. Lienhard, “A Physical-Level LCD Driver Model and Simulator with Application to Pixel Crosstalk Suppression,” IEEE Transactions on Consumer Electronics, Vol. 52, No. 3, pp. 1027–1034, 2006.

N. Sako, H. Sasama, H. Kitayama, and H. Fukasawa, “Single-chip Driver for 65k Color STN-LCD with Half Column Voltages in a MLA Drive System,” SID Digest, Vol. 34, No. 1, pp. 324–327, 2003.

I. Washizuka and A. Sakamoto, “Driving Method to Reduce Shadowing for STN-LCD Module,” Proceedings of International Display Workshop, pp. 297–300, 1997.

Passive-matrix is an LCD technology that uses a grid of vertical and horizontal wires to display an image on the screen. Each pixel is controlled by an intersection of two wires in the grid. By altering the electrical charge at a given intersection, the color and brightness of the corresponding pixel can be changed.

While passive-matrix displays are relatively simple and inexpensive to produce, they have a few drawbacks. Since the charge of two wires (both vertical and horizontal) must be altered in order to change a single pixel, the response time of passive-matrix displays is relatively slow. This means fast movement on a passive-matrix display may appear blurry or faded, since the electrical charges cannot keep up with the motion. On some passive-matrix displays, you may experience "ghosting" if you move the cursor quickly across the screen.

Since passive-matrix monitors do not display fast motion well, most modern flat screen displays use active-matrix technology. Instead of managing pixels through intersections of wires, active-matrix displays control each pixel using individual capacitors. This allows pixels to change brightness and color states much more rapidly. While most of today"s computer monitors and flat screen televisions have active-matrix screens, passive-matrix displays are still used in some smaller devices, since they are less expensive to produce.

1. Passive Matrix LCD: It uses a grid of vertical and horizontal conductors comprised of Indium Tin Oxide to create an image. Each pixel is controlled by an intersection of two conductors. It represents the off state of LCD i.e the pixel is OFF.

2. Active Matrix LCD: It uses thin-film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location. The active pixel is called so because it has the ability to control the individual pixels and switch them quickly. thin-filmwhich

Difference between Active Matrix LCD and Passive Matrix LCD:Active Matrix LCDPassive Matrix LCDIt uses thin film transistors that are arranged in a matrix on a glass surface. To control the voltage tiny switching transistors and capacitors are used at each pixel location.It uses grid of vertical and horizontal conductors such that the intersection of two of those conductors allows for controlling a single pixel.

Active matrix LCDs are used in full-color LCD TVs monitors, cell phones etc.They are used in calculators display or a digital wrist watches where the display contains a limited number of segment and does not require full color. They are often created for custom applications.

On an elaborative note, passive and active displays also have several types which run down their very own category. For example, passive LCDs may be of the following types:Monochrome TN (Twisted Nematic) – here the liquid crystal cells do not require any current to flow past them and automatically work with lower voltages provided by the batteries.

LCD connected to this controller will adjust itself to the memory map of this DDRAM controller; each location on the LCD will take 1 DDRAM address on the controller. Because we use 2 × 16 type LCD, the first line of the LCD will take the location of the 00H-0FH addresses and the second line will take the 40H-4FH addresses of the controller DDRAM; so neither the addresses of the 10H-27H on the first line or the addresses of the 50H-67H on the second line on DDRAM is used.

To be able to display a character on the first line of the LCD, we must provide written instructions (80h + DDRAM address where our character is to be displayed on the first line) in the Instruction Register-IR and then followed by writing the ASCII code of the character or address of the character stored on the CGROM or CGRAM on the LCD controller data register, as well as to display characters in the second row we must provide written instructions (C0H + DDRAM address where our character to be displayed on the second line) in the Instructions Register-IR and then followed by writing the ASCII code or address of the character on CGROM or CGRAM on the LCD controller data register.

As mentioned above, to display a character (ASCII) you want to show on the LCD, you need to send the ASCII code to the LCD controller data register-DR. For characters from CGROM and CGRAM we only need to send the address of the character where the character is stored; unlike the character of the ASCII code, we must write the ASCII code of the character we want to display on the LCD controller data register to display it. For special characters stored on CGRAM, one must first save the special character at the CGRAM address (prepared 64 addresses, namely addresses 0–63); A special character with a size of 5 × 8 (5 columns × 8 lines) requires eight consecutive addresses to store it, so the total special characters that can be saved or stored on the CGRAM addresses are only eight (8) characters. To be able to save a special character at the first CGRAM address we must send or write 40H instruction to the Instruction Register-IR followed by writing eight consecutive bytes of the data in the Data Register-DR to save the pattern/image of a special character that you want to display on the LCD [9, 10].

We can easily connect this LCD module (LCD + controller) with MCS51, and we do not need any additional electronic equipment as the interface between MCS51 and it; This is because this LCD works with the TTL logic level voltage—Transistor-Transistor Logic.

Pins 7–14 (8 Pins) of the display function as a channel to transmit either data or instruction with a channel width of 1 byte (D0-D7) between the display and MCS51. In Figure 6, it can be seen that each Pin connected to the data bus (D0-D7) of MCS51 in this case P0 (80h); P0.0-P0.7 MCS-51 connected to D0-D7 of the LCD.

Pins 4–6 are used to control the performance of the display. Pin 4 (Register Select-RS) is in charge of selecting one of the 2 display registers. If RS is given logic 0 then the selected register is the Instruction Register-IR, otherwise, if RS is given logic 1 then the selected register is the Data Register-DR. The implication of this selection is the meaning of the signal sent down through the data bus (D0-D7), if RS = 0, then the signal sent from the MCS-51 to the LCD is an instruction; usually used to configure the LCD, otherwise if RS = 1 then the data sent from the MCS-51 to the LCD (D0-D7) is the data (object or character) you want to display on the LCD. From Figure 6 Pin 4 (RS) is connected to Pin 16 (P3.6/W¯) of MCS-51 with the address (B6H).

Pin 5 (R/W¯)) of the LCD does not appear in Figure 6 is used for read/write operations. If Pin 5 is given logic 1, the operation is a read operation; reading the data from the LCD. Data will be copied from the LCD data register to MCS-51 via the data bus (D0-D7), namely Pins 7–14 of the LCD. Conversely, if Pin 5 is given a voltage with logical 0 then the operation is a write operation; the signal will be sent from the MCS51 to LCD through the LCD Pins (Pins 7–14); The signal sent can be in the form of data or instructions depending on the logic level input to the Register Select-RS Pin, as described above before if RS = 0 then the signal sent is an instruction, vice versa if the RS = 1 then the signal sent/written is the data you want to display. Usually, Pin 5 of the LCD is connected with the power supply GND, because we will never read data from the LCD data register, but only send instructions for the LCD work configuration or the data you want to display on the LCD.

Pin 6 of the LCD (EN¯) is a Pin used to enable the LCD. The LCD will be enabled with the entry of changes in the signal level from high (1) to low (0) on Pin 6. If Pin 6 gets the voltage of logic level either 1 or 0 then the LCD will be disabled; it will only be enabled when there is a change of the voltage level in Pin 6 from high logic level to low logic level for more than 1000 microseconds (1 millisecond), and we can send either instruction or data to processed during that enable time of Pin 6.

Pin 3 and Pin 15 are used to regulate the brightness of the BPL (Back Plane Light). As mentioned above before the LCD operates on the principle of continuing or inhibiting the light passing through it; instead of producing light by itself. The light source comes from LED behind this LCD called BPL. Light brightness from BPL can be set by using a potentiometer or a trimpot. From Figure 6 Pin 3 (VEE) is used to regulate the brightness of BPL (by changing the current that enters BPL by using a potentiometers/a trimpot). While Pin 15 (BPL) is a Pin used for the sink of BPL LED.

4RSRegister selector on the LCD, if RS = 0 then the selected register is an instruction register (the operation to be performed is a write operation/LCD configuration if Pin 5 (R/W¯) is given a logic 0), if RS = 1 then the selected register is a data register; if (R/W¯) = 0 then the operation performed is a data write operation to the LCD, otherwise if (R/W¯) = 1 then the operation performed is a read operation (data will be sent from the LCD to μC (microcontroller); it is usually used to read the busy bit/Busy Flag- BF of the LCD (bit 7/D7).

5(R/W¯)Sets the operating mode, logic 1 for reading operations and logic 0 for write operations, the information read from the LCD to μC is data, while information written to the LCD from μC can be data to be displayed or instructions used to configure the LCD. Usually, this Pin is connected to the GND of the power supply because we will never read data from the LCD but only write instructions to configure it or write data to the LCD register to be displayed.

6Enable¯The LCD is not active when Enable Pin is either 1 or 0 logic. The LCD will be active if there is a change from logic 1 to logic 0; information can be read or written at the time the change occurs.

There are many different display technologies such as LCD, OLED, EPD, and ECD. They are all based on fundamentally different technologies with various driving requirements. That being said, all of them share some basic ideas of how to drive them. In this article, I will explain some fundamentals in display driving. This information is relevant whether you are a professional engineer designing display applications, a hacker exploring seven segment displays for your Arduino projects, or simply if you are just interested in this topic.

These display types can be driven by multiple methods with different degrees of complexity. A general guideline is that more pixels come with a higher driving complexity. There are two main types of driving, direct drive suitable for a low pixel count or matrix drive that can handle millions of pixels.

Direct drive is a common driving method for segmented displays such as seven segment displays. It is a very simple option where each display segment is connected to a pin. A segment is addressed simply by setting a voltage to the targeted segment. In some cases, this type of display can be driven directly from many microcontrollers, eliminating the need for a dedicated display driver. This, in turn, reduces the cost of the overall system. This is the case for the Rdot display which can be connected to practically any MCU with accurate driving voltage. An advantage with direct drive is the possibility to address all the pixels at the same time. For LCDs, direct drive is the driving method that offers the highest contrast.

The drawback with direct drive is the high pin count for a display with lots of segments. For a display with more than 100 segments direct drive is not recommended. From 30 to 100 segments, direct drive could be a good option. Below 30 segments a direct drive is very often the best choice. In the figure below I"m comparing direct drive and matrix drive in terms of electrodes required for different segment count.

In a passive matrix display, pixels are addressed row by row, this is called time multiplexing. That means that all pixels on row 1 are updated first, then all pixels on row 2, etc.. meaning that for a display with three rows, each row is only addressed ⅓ of the total time. On retro displays, it is sometimes possible to see this effect as a continuous sweeping across the screen. For LCDs, this reduces the contrast of the display which, in turn, limits the total number of rows possible. This method is often called multiplex driving for segmented displays. Passive matrix drive is a cost-effective method to drive displays as it doesn"t require any additional hardware. However, just a few display technologies have the characteristics required for passive matrix drive.

The Rdot display technology has great potential to become the best passive matrix technology. This is because the technology is bistable (can maintain its state even when it is not addressed). This means that when one row is updated the driver can continue and update the other rows without losing the contrast on the first row. Passive matrix Rdot display is still under development but is planned to reach market during 2019. This display will be revolutionary to the display industry as it will be the first passive matrix display in high resolution and the first fully printed passive matrix display. In addition, it will still keep the low price point and maintain the bendability. If you want to follow the development, sign up for our newsletter!

The sophisticated display, that you most likely are looking at right now, is based on active matrix technology. In an active matrix, each pixel contains at least one transistor. More often, there are multiple transistors and capacitors. In an OLED for example, each pixel contains a quite sophisticated circuit with 5-10 transistors.

By adding transistors to the pixel, it can more easily be controlled. This is partly because transistors offer a threshold voltage which is an important feature for a display matrix to function properly. A capacitor, on the other hand, functions as an energy storage when the pixel is not addressed. In this way, all pixels can maintain their state even for a large number of rows. The Apple iMac display, for example, can in this way achieve 2880 rows without a problem. The drawback with active matrix is the high price point since the fabrication requires expensive deposition processes. For that reason, active matrix is mainly suitable for high-end displays.

There are two main display types; segmented and graphical. Direct drive is not suitable for graphical displays due to the high number of interconnections between the display and the controller. Matrix drive solves this problem with time multiplexing. There are two types of matrix drive; passive or active. Active drive is only suitable for high-end displays as it is an expensive technology. Passive matrix is a very inexpensive technology, but so far no high-resolution displays based on passive matrix have been demonstrated. Rdot will revolutionize the display industry during 2019 by introducing a passive matrix display that is both flexible and low-cost.

If you will have people looking over your shoulder, item 2 is critical since the angle that they have to the screen will almost certainly be non-optimal for a passive

matrix screen. So if you frequently want someone else to look at your screen (say if you"re doing a sales demo without a projection device), you absolutely need the

active matrix. On a positive note, the passive matrix pretty much makes people sitting next to you in meetings unable to decipher what you are typing without being

a Passive screen, because of the slow response time, the pixels that compose an image of the cursor never get a chance to get black before they"re told to go back

The largest number of simultaneous colors that most passive matrix displays can handle is 256. On an active matrix display, up to 16.7 million colors can be

Finally, since the passive screen is slower, the screen is physically divided into two pieces which are scanned simultaneously. This results in a faint line across the

Active matrix is a lot more expensive, and because of manufacturing issues, is also typically in short supply (so you may have to wait for a while to get a machine

There are some other issues. Active matrix displays may occasionally lose pixels (permanently). So you may have a tiny green (or other colored dot) show up

someplace on your display. Most manufacturers will replace the screen if more than a certain number of pixels fail. This happens more rarely with passive matrix

As the key component behind liquid crystal displays (LCD), these materials change light polarization to create vibrant, high-resolution images on digital screens. The growth of LCD technology has helped propel the larger display panel market enormously, with industry valuation projected to reach $178.20 billion by 2026.

A prolific variety of LCD types has been developed to best meet their exact use-cases and end-environments. Displays may be optimized for power consumption, contrast ratio, color reproduction, optimal viewing angle, temperature range, cost, and more.

Passive Matrix LCDs are addressed with common and segment electrodes. A pixel or an icon is formed at the intersection where a common and a segment electrode overlap. Common electrodes are addressed one-at-a-time in a sequence. Segment electrodes are addressed simultaneously with the information corresponding to all pixels or icons connected to the current common electrode. This method is referred to as multiplexing.

Passive Matrix LCDs offer a cost advantage (both parts and tooling) and are highly customizable. The counterpart to Passive Matrix displays are Active Matrix displays.

Active-Matrix LCDs were developed to overcome some of the limitations of Passive Matrix LCDs – namely resolution, color, and size. Within an Active-Matrix LCD, an “active element” is added to each pixel location (the intersection between a horizontal row and vertical column electrode). These active elements, which can be diodes or transistors, create a threshold and allow control of the optical response of the liquid crystal structure to the applied voltage. Transistors are used as switches to charge a capacitor, which then provides the voltage to the pixel. Whenever a row is turned on, one at a time, all transistor switches in that row are closed and all pixel capacitors are charged with the appropriate voltage. The capacitor then keeps the voltage applied to the pixel after the row is switched off until the next refresh cycle.

Furthermore, the processes used for manufacturing Active-Matrix LCDs can create much finer details on the electrode structure. This allows splitting each pixel in three sub-pixels with different color. This together with the better voltage control allows full color displays.

The transistor switches used in Active Matrix Displays must not protrude significantly above the surface of the display substrates lest they might interfere with a uniform liquid crystal layer thickness. They must be implemented in thin films of suitable materials. Hence, the name Thin Film Transistors (TFT). While AM and TFT have a different meaning, they are often used interchangeably to indicate a higher performance display.

Currently the most common Electronics Display Technology on the market is LCD technology and among LCD technologies, TFT display technology is the most widely used across consumer applications (laptops, tablets, TVs, Mobile phones, etc.) as well as many industrial, automotive, and medical applications.

As the first commercially successful LCD technology, Passive Matrix Twisted Nematic (TN) LCDs use a 90° twist of the nematic LC fluid between two polarizers to display information. The twist of the LC fluid either blocks light from passing through the LCD cell or allows light to pass, depending on the applied voltage. The applied voltage changes the twisted nematic orientation into an orientation that does not change the polarization of tight. This is called the TN effect.

Initially, Passive TN LCDs were used in segmented, icon, or character displays where an image element was turned “on” and “off” depending on how the fluid was driven. Improvements were made along the way to address the limited viewing angle of TN technology, which can suffer from contrast loss or even inversion at shallow angles.

The numbers of rows or icons that can be addressed in a TN display without Active Matrix addressing is very limited. This is related to how strongly the liquid crystal responds to the applied voltage. Twisting the LC nematic fluid more than 180 degrees (typically between 210 and 270 degrees) causes the display to require a much smaller voltage difference between on and off pixels. This in turn allows addressing of many more rows without an active matrix. Displays with a twist between 210 and 270 degrees are called Super Twisted Nematic displays.

The advantage of these technologies is a much wider and more symmetrical viewing angle along with the elimination of the contrast inversion (or color shift) seen in TN TFT LCDs when viewed from various angles. IPS and FFS displays also are less sensitive to pressure, which is a big advantage in touchscreen displays.

Legacy LCDs normally have the driver ICs (integrated circuit) mounted on a printed circuit board (PCBA) which consists of a flat sheet of insulating material used to mount and connect the driver IC and electronic periphery to the LCD. PCBs can be a single-sided, double-sided or multi-layer.

New Vision Display (NVD) has decades of experience designing and manufacturing custom display and touch panel assemblies for some of the world’s largest original equipment manufacturers (OEMs) in the automotive, medical, industrial, and consumer markets.

TFT is an acronym for Thin Film Transistor, and it is a technology used in Liquid Crystal Display screens. It came about as an improvement to passive-matrix LCDs because it introduced a tiny, separate transistor for each pixel. The result? Such displays could keep up with quick-moving images, which passive-matrix LCDs could not do.

The technology improved on the TN (Twisted Nematic) LCD monitor because the shifting pattern of the parallel, horizontal liquid crystals gives wide viewing angles. Therefore, IPS delivers color accuracy and consistency when viewed at different angles.

Both TFT and IPS monitors are active-matrix displays and utilize liquid crystals to paint the images. Technically, the two are intertwined because IPS is a type of TFT LCD. IPS is an improvement of the old TFT model (Twisted Nematic) and was a product of Hitachi displays, which introduced the technology in 1990.

Impressive Display Effect: TFT displays use flat glass plates that create an effect of flat right angles. Combine this with the ability of LCDs to achieve high resolutions on small screen types, and you get a refreshing display quality.

Liquid Crystal Display (LCD) is a front panel display that utilizes liquid crystals held between two layers of polarized glass to adjust the amount of blocked light. The technology does not produce light on its own, so it needs fluorescent lamps or white LEDs.

As explained earlier, TFT improved on the passive-matrix LCD design because it introduces a thin film transistor for each pixel. The technology reducescrosstalkbetween the pixels because each one is independent and does not affect the adjacent pixels.

LED screens are like the new kids on the block in the display market, and they operate very differently from LCDs. Instead of blocking light, LEDs emit light and are thinner, provide a faster response rate, and are more energy-efficient.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey