waterproof lcd arduino quotation

Alibaba.com has a massive stock of durable and proficient arduino tft screen at your disposal that are worth every penny. These spectacular arduino tft screen are available in varied sizes, colors, shapes, screen patterns and models equipped with extraordinary features such as being waterproof, heatproof and much more. These are energy-efficient devices and do not consume loads of electricity. The arduino tft screen you can procure here are equipped with advanced LED chips, dazzling HD quality, and are fully customizable.

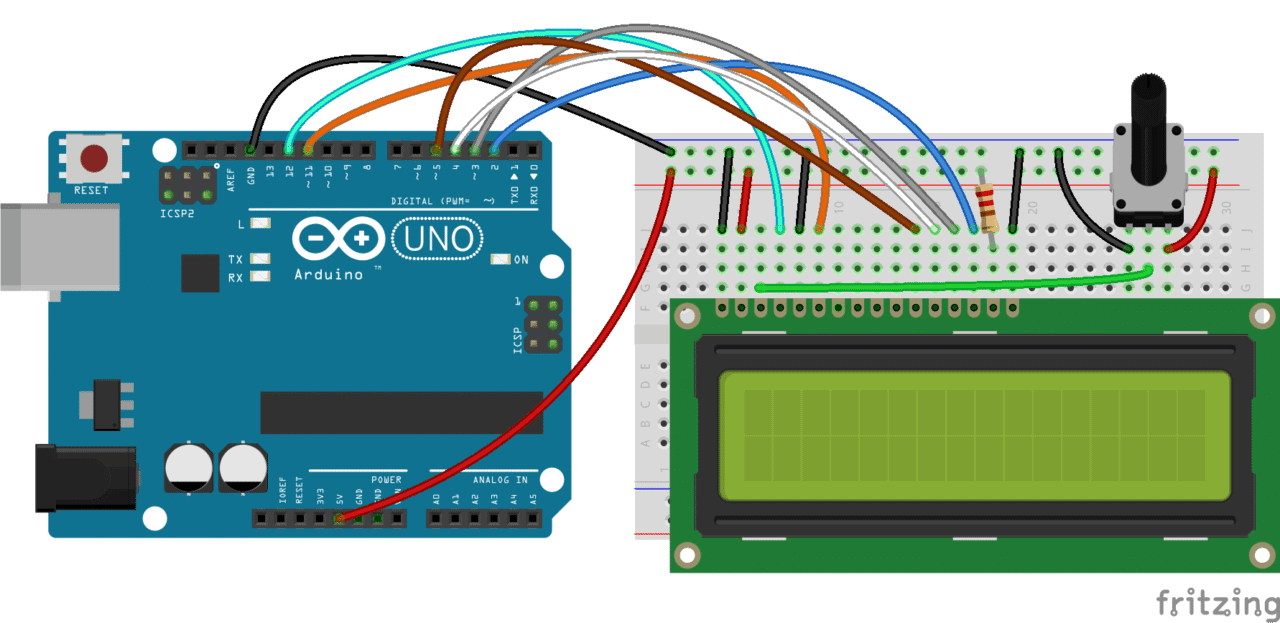

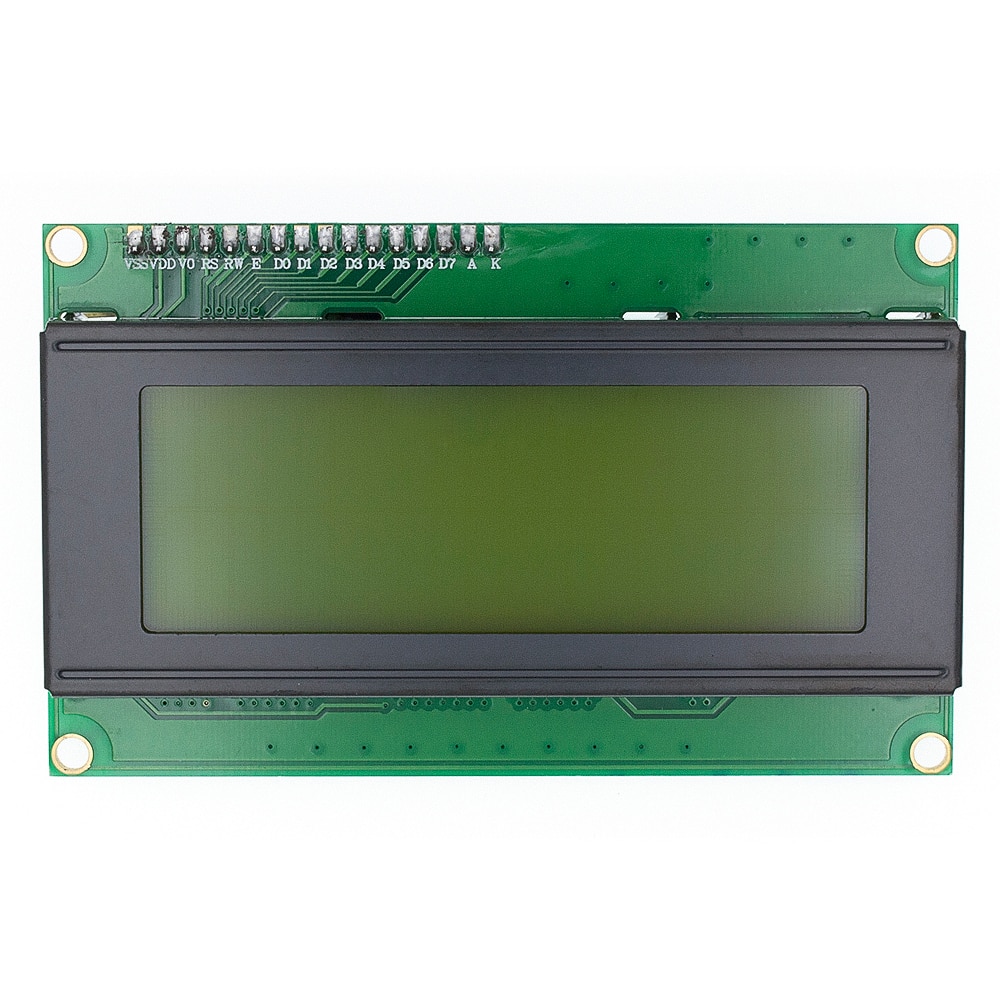

After some more research & experimenting, I’m thinking the best solution is a hybrid panel. What I’ll do is use new 3.375" gauges for the speedometer & tachometer, the bikes’ original LCD for fuel, coolant temp, and gear position, and a 16x4 LCD for oil temp., oil pressure, volts, and air temp. I can use 18B20 sensors for the oil & air temp, I have a 5V oil pressure sensor that outputs volts from .5 to 4.5, and I’ve learned how to construct a voltage monitoring circuit. This avoids the headache of speedometer & odometer programming. Combining all of this into one sketch will be another learning experience.

I will be able to mount the LCD under an aluminum dash panel in a small plastic box with a Plexiglas cover & neoprene gasket to make it waterproof as much as possible. The bike will have a fairing with fuse panel, so I will likely mount the UNO in there out of the elements, maybe 2’ from the LCD. Worst case I could get a larger box & mount both under the dash panel.

I am making a small device that would be fitted on motorcycles. The device"s case will be a 3D printed case which houses a 2.2 inch SPI TFT display and a ESP32 module. I wanted to make the display waterproof so that it will keep working even in slight rain. I would be waterproofing ESP32 with sealing gel or epoxy. I just want a solution for the LCD display.

Look at your LCD display and tell me which side is waterproof. The front side. So, if your LCD is inside the box with only the glass front exposed, how is that NOT water proofed? Perhaps you need a rubber gasket between the glass front and your box.

Degreasing is critical, Tech Spray and others have electronic compatible degreasers. Check the specifications of your parts and make sure what you use is compatible. No LCD I’m aware if can take this unless it’s s specialty type.

Any component that is water sensitive such as LCD’s come with their own problems. Since ones pre-sealed against moisture are outrageously pricey you can build an enclosure just for them and seal that. It’s not hard, just tedious.

These appear to be bare-glass LCDs, so you will still need to drive them. An Arduino can produce the required 5VAC to drive them (DC will ruin an LCD), but if you multiplex the digits you shouldn"t need an obscene number of pins -- even an ATmega328/32u4 like the Uno/Nano/Micro/ProMini might have enough. You need 8 pins for the segments (or 7, if you never want to display the decimal point) plus 1 pin per digit, hopefully leaving just enough for Wifi/Ethernet/Bluetooth to grab the train times with.

It"s inconceivable that someone hasn"t already written an Arduino library for multiplexing bare-glass LCDs, but I didn"t find any with a quick Google?

I successfully built a project using 7 segment LED display, it works perfect! Very happy with the function of the code with LED display - the only problem is it"s not viewable outside where I plan on using it most of the time so after a ton of research it appears LCD 7 segment might be a good option, similar projects use this type of LCD display (if you have a better idea, I"d like to hear it and why it"d work well)

This project only needs to display numbers and the numbers are updated every 1 second. I think the static LCD will be perfect and it"s clearly viewable even in direct sunlight, I only need 3 segments and the LCD"s I currently have are Lumex 3 segment. My goal is to have nice large 3 digit numbers clearly displayed that can be read outside, the numbers will update in the code with millis() every second.

The issue I"m having transferring over my design to use a reflective static LCD - I can"t seem to find any information more than an explanation on the theory of how to correctly drive an LCD since it requires reversing polarity (AC) I have some ideas on how it might work and I"ve seen a proof of concept using XOR for one pin, driving the com pin and flipping the other pin with an XOR, the explanation I found basically ended there and left me with no practical idea where to start, I"m looking everywhere and can"t find anything on driving a static LCD with arduino so I"d appreciate any help pointing me in the right direction, I am completely stuck right now and would appreciate any help.

I have a mid 80’s Honda Sabre motorcycle, and the gauge panel is severely broken. I was able to salvage everything except the speedometer. The parts for it are no longer available, and used parts are sky high in cost when available, plus they’re 25 years old. The bike uses an electronic speedometer & tachometer, along with a digital display that had LCD gear positions (via 7 wires- one for each gear and neutral), fuel level, and water temperature. The bike predates the engine control modules and data bus setups of newer bikes- it’s fairly old school. The wheel speed sensor uses a three wire setup: an 8V input from the dash, sensor ground, and outputs 0~4 to 8V back to the gauge per the shop manual. I’ve looked at late model bike dashes, and many use CAN BUS setups that I’m unfamiliar with. Some older ones still uses similar sensor data as what mine does, so they are a possibility, but I’d have to add-on gauges to monitor all the things I want to monitor. I’ve looked at dashes (via wiring diagrams & shop manuals) from all the Japanese models as well as Aprilia, Buell, Ducati, and Triumph and even a couple of snowmobiles. All are either lacking a feature I want or they cost way too much. What I’d like to do is hijack a later model dash with an LCD panel & make it display the stuff I want… but I digress.

I found some LCDs with built-in serial graphics here. I downloaded the software tool and have been learning how to use it. Of course, I’d need either a waterproof LCD or secure casing for it/them. I have a basic understanding of electronics, and the ability to learn about things- I’ve self-taught myself things such as welding and AC repair.

I’d like to build an Arduino project to drive an LCD (or possibly 2, speed & RPM). What I’m planning to monitor is as follows, along with my comments:

I don’t need fancy displays on the LCD, just numbers & letters. I drew a prototype using some software and have attached a JPG of what I’d like to end up with (single screen).

You could do capacitive buttons, but a large amount of water on the face can cause problems. The advantage is that these too could be mounted to the back of a clear cover just like the LCD, so you"d need to make exactly 0 openings in the face of the enclosure.

Crystalfontz has a wide variety of LCD display products. Including ePaper, OLED, TFT and accessories. Watch our LCD videos below to see our display solutions in action.

This is a quick video showing our new 1.3 inch TFT LCD. This is a small, full-color TFT. It"s controlled via 4-wire SPI. It has a ST7789H2 controller. This display runs off a single 3.3v supply which controls the logic and backlight.

Check out this small, low power transflective LCD display. Available in many options including with and without a backlight, breakout board, or a complete development kit.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey