crystal clear transparent lcd display free sample

I saw a really cool video of a PC case called "Snowblind", that had a transparent LCD Screen as a side panel. I was amazed over how cool it was. The only problem was that it was really expensive. Therefore, I tried making my own! In this instructables I will go through how I made it, and how you could make your own. The best of all, since it was made from an old monitor that was thrown away, it was basically free! I just added some LED strips on the inside of the case to get better contrast on the screen. You could probably re-use the monitors backlight, but it"s safer and easier to just get some cheap LED strips.

First, remove the frame of the panel. It is fixed with clips, so just bend the frame a little and lift the frame up. Next, separate the front LCD from the backlight. For the next step, you will have to be careful. This step involves removing the anti glare film. It is glued to the panel, and therefore it"s easy to break the LCD when trying to remove it.

Then you are done modding the LCD! Now, you can hook it up to the panel and test it. Just be careful with the ribbon cables going from the LCD PCB to the panel.

The side panel of this case fits the LCD perfectly. Just line it up to the side facing the back, and to the top, and use some tape to tape it to the glass. Then, use some vinyl on the outside where the LCD is not covering the glass.

It"s really important to have lots of lights inside the case, to make it easier to see the LCD. Therefore, try to fill the case with even more LED strips.

You can now power up the computer, open the screen settings and set it up for dual screens. You might have to flip the display 180 degrees too. When you have done that, open Wallpaper Engine and set a wallpaper of choice!

Hey I have a little question, I also have a Dell 1905FP, but I think it"s an older model because I don"t have a ribbon cable but a normal cable with a plug. My problem is that I have peeled off one film but it still looks like there is a second film on the back because it is still a little blurry. But I"m afraid that if I try to pull them off, my LCD display will break. Maybe you have an idea. Thanks in advance

Terrific job! May I ask why you would need to remove the front polarizer? If my understanding is correct, both the front and back polarizers are needed in order for the LCD to work properly (i.e., the light gets polarized by the back polarizer first, and then passes through the front polarizer)? You comments will be appreciated!

I think you should have more pics and info about the re- mounting the LCD. After all if you don"t do it right all that work is for nothing. While I understand your wiring diagram, I think that it should be explained and a larger part of this Instructible...for example to get white lite your are powering all 3 lanes (red,green,blue) on the RGB tape.

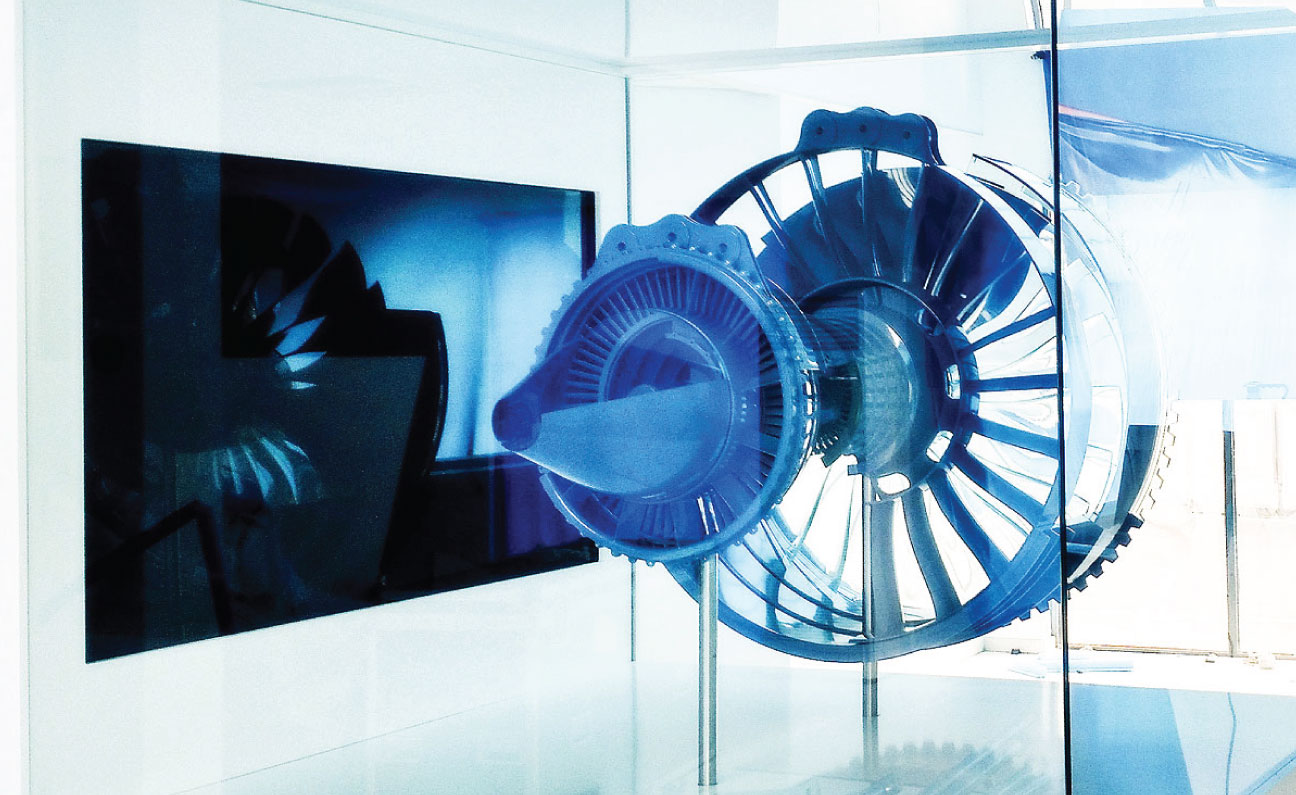

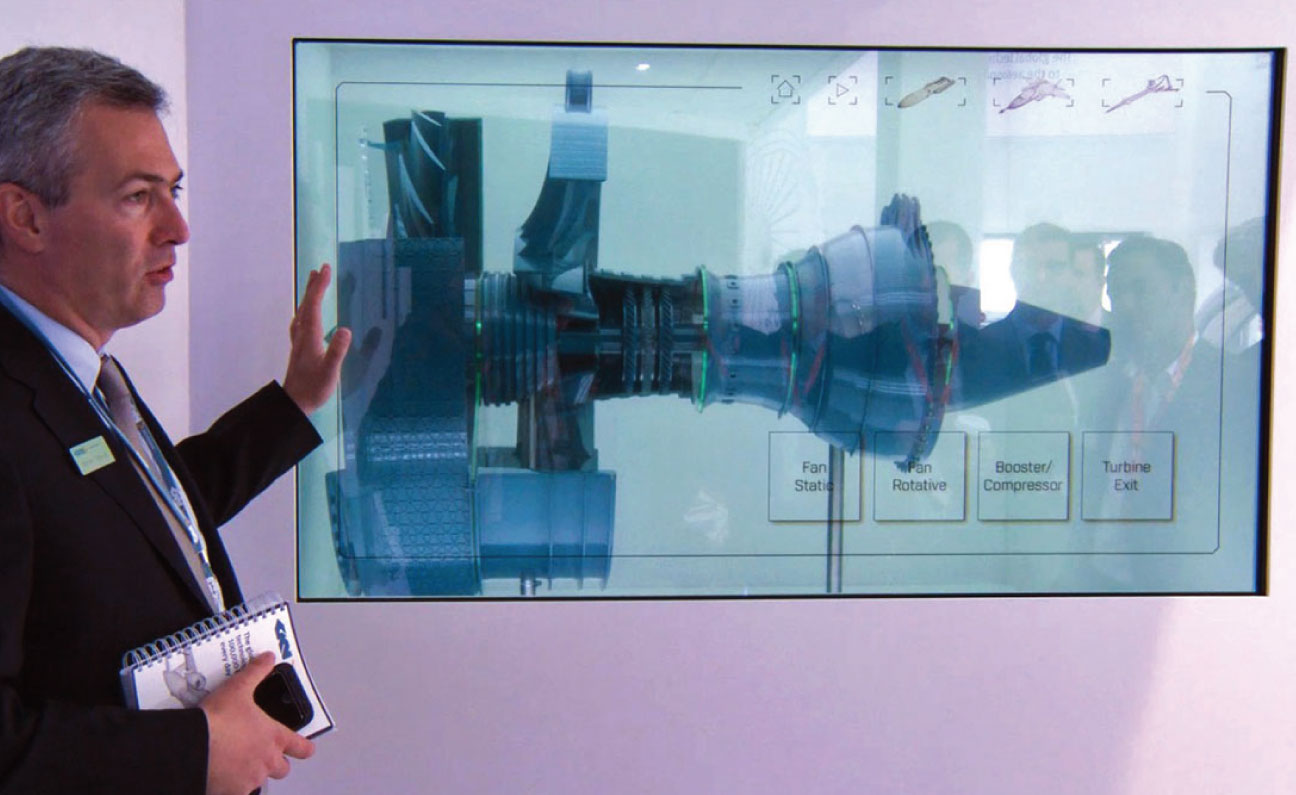

Transparent LCD’s provide an innovative display solution opening up new ways for brands to promote their products and services. Examples include retail stores looking to advertise a new fashion clothing or accessory, museums securely housing a precious artifact with information displayed on screen or brands looking to launch a new product at a live event or show. The opportunities are endless!

Our Transparent LCD Displays include a Grade A LCD panel with metal bezel protecting the edges / electronics and a media board supporting HDMI or VGA inputs from your PC, Laptop or Media Player.

Transparent screen technology offers intriguing ways to deliver visual information to your audience, being used to reveal or conceal products, objects or artefacts behind the screen.

The combination of HD LCD technology (4K on our 65″, 86″, 98″ version) with a transparent screen substrate opens up creative avenues that were previously closed with traditional LCD displays. Solid black pixels on a transparent background can be used in intriguing ways to hide (and gradually reveal) whatever is behind the screen.

Our Transparent LCD monitors are designed for integration into the customers own furniture housing or display case while our Transparent LCD showcases offer a complete solution including the display, housing and backlight with white or black options available on request. We can also offer custom freestanding options for POP / POS displays. Transparent LCD’s are predominantly fully housed however we’ve recently developed an innovative housing method using a high brightness LED panel which allows the display case sides to remain transparent for improved visibly into the display case.

Using their original design as a starting point, we worked closely with the team at Nike to adapt to the mechanical aspects of the design, the result was a sleek and minimalist set of nine Transparent LCD Display Screens, custom built to suit the applications requirements, bringing Nike’s original concept ideas to life.

Retail windows, interactive booths, display cases, interactive games, vending machines, drinks coolers… the uses for this amazing technology are limited only by your creativity.

Transparent LCD’s comprise of an LCD panel without the backlight with white pixels appearing as transparent. In order to display an image, the Transparent LCD needs to be integrated into a housing with a high bright LED backlight.

We can also offer more complete solutions like our Transparent LCD Showcase that comes fully contained and ready to use with a powerful backlighting system to guarantee the best picture quality.

Yes in order to display an image Transparent LCD’s need to have a strong backlight. Notoriously Transparent LCD’s have also needed some form of housing to achieve optimum image quality, however, Nike’s House of Innovation paired our Transparent LCD’s with powerful, oversized backlights that allowed the screens to be mounted with no surround but still producing a high-quality image.

Transparent LCD’s are arguably the most popular transparent screens but are hindered by their need for a backlight to operate. For applications looking for a similar effect without the backlighting, Transparent OLEDs require no housing or surround but are only currently available in a 55″ screen size with HD quality. For larger transparent screen applications, Transparent LED’s are recommended with external and internal solutions usually installed to glass facades for the impact of an led screen without compromising the view from inside the building.

We also offer transparent projection technologies including our Clearview Rear Projection Film featured in Guardians of the Galaxy as well as at the 83rd Oscars celebration and MTV EMA awards.

Transparent LCD’s are a great way to combine physical and digital displays in one central place making them a popular choice for museums and exhibitions. Our transparent screens can also be integrated into display furniture and appliances & vending machines like freezer doors for supermarkets. Other uses include POS displays, store window displays, trade shows and product launches.

We manufacture in Britain and ship worldwide – if you need further information, a pricing quote, or want to discuss ideas for using our Transparent LCD Display click the link below to contact us, email us via info@prodisplay.com or call us on +44 (0)1226 361 306.

Christmas magic glass dome with a sequined christmas tree blank template festive new year realistic 3d design christmas crystal ball red background vector illustration

Awesome little transparent OLED display. Its a 128x56 pixels and 1.51 inch diagonal. Super-bright, monochrome (light blue). We powered it up with a Seeeduino for this demonstration.

A large transparent liquid crystal display (LCD) prototype with ultrahigh transmittance and good see-through property is demonstrated in this paper. The transmittance reaches more than 20% by introducing the RGBW pixel arrangement, a thin color filter process, a large aperture ratio design, as well as antireflective polarizer film. The see-through image quality is also greatly improved by suppressing the blurring by using domain reduction pixel design. All these approaches are applicable for large LCD panel products, and we expect broad applications of large transparent LCDs in the near future.

LCD Transparent Displays, transparent screens, transparent monitors, see through screens, transparent touch screen technology, and kits from CDS as we have our own range of transparent screens / displays and transparent video screens manufactured for us, and as we control the manufacturing, we can not only offer more sizes than anyone else in the world, but also guarantee stable supply, long term availability LCDs with amazing quality. We have replaced the Samsung Transparent Displays / see through Displays and LG Transparent OLEDs that are no longer available!

CDS has increased the use of these see through screens / see through displays / see through computer screens / clear monitors across the world including touchscreen computer screens combined with the transparent LCD touch screens and Transparent OLED displays.

VarTech’s high bright sunlight readable LCD monitors and touchscreen displays give users crystal clear images and video in direct sunlight and outdoor applications.

Our high bright sunlight readable LCD monitors and touchscreen displays have brightness levels ranging from 1000 nits to 1600 nits. These brightness levels far exceed consumer-grade monitors which typically produce 150 to 350 nits brightness. VarTech’s high bright sunlight readable LCD technology ensures crisp, highly viewable videos and images in direct sunlight and high ambient light work environments.

VarTech’s high bright sunlight readable displays use industrial-grade enhanced LED backlights to increase luminance without increasing heat. Proprietary Enhanced Light Transmission Technology (ELTT) gives our screens exceptional clarity, wide viewing angles, and maximum light reflection. Optical bonding reduces light reflection and increases ruggedness by providing a solid transparent bond between the thin-film-transfer (TFT) LCD screen and the front face of the monitor or touchscreen display.

These light enhancements along with VarTech’s quality construction and rugged mechanical design make our industrial grade high bright sunlight readable display products a superior high bright solution for applications that require clarity, intensity, brilliance, and reliable performance from your monitor or computer.

/img/iea/LBGR1VDEO2/youtube-duo-build-see-through-lcd-computer-screen-like-its-the-year-3020.jpg)

Quite a feat of technology, transparent displays become more widely available and affordable each year. If you are unsure whether to invest in them, we point out the advantages and usages they offer to outdoor advertising below to shed more light on the continually growing potential of transparent displays which might sway you in their direction!

Not all transparent displays are the same—that’s the first thing to know. It’s important to establish which variant of transparent displays suits your needs best. Now, if you’re looking to find out what the best transparent display type is and be done with it, we’re sorry to disappoint you. Some are better than others for certain circumstances. We start off by covering two of the most important types.

Just like standard LCD displays, transparent LCD displays need a light in the back of the screen to produce a visible image. The pixels on an LCD screen do not emit light but instead rely on the backlight to provide it, then block out the output of the blacklight to display appropriate colors. This makes them very good to use in well-illuminated areas, especially outdoors.

When it comes to their weaknesses, as LCD displays need the backlight to produce images, they’re not the best at producing a pure black color. Furthermore, their brightness is limited and the viewing angle can impact the vibrancy of colors and picture quality.

While LCD displays block light, each pixel in any OLED display emits its own light. Not requiring backlight illumination makes OLED displays particularly powerful in darker areas and indoors. We find a good example for this in LGs transparent OLEDs used assubway windows. There are several other benefits unique to OLEDs such as colors staying vibrant from all viewing angles. The absence of backlights physically installed in the display allows for thinner and lighter displays.

OLED displays, however, are more sensitive to moisture and discoloration if exposed to direct sunlight and heat, making them a questionable choice for outdoors. They are also more expensive to manufacture. Keep in mind, though, that OLED displays are likely to become cheaper in the future. If you’re not prepared to invest in them just yet, they’re definitely worth keeping an eye on!

Initially you might think a transparent display of any kind is limited in interactive features, but know that interactivity is not at all a challenge. It is in fact highly recommended you implement interactivity with transparent displays if suiting your needs. Even though a transparent display is not brand new technology, it’s still very likely to engage people to interact.

A good example for the potential of interactivity came during theCOVID-19 pandemic. With clear physical barriers becoming more prominent, it offers more opportunities for transparent displays. Even if we take interactivity out of the equation, a transparent display can fill in that awkward barrier that divides us and make it appear as more of a luxurious convenience rather than yet another reminder of the pandemic we all know quite well by now.

Even though they’ve been available for a little while, transparent displays haven’t reached their peak diffusion just yet. The beauty of this for anyone getting them now is that they still draw attention and excitement to them.

Transparent LCD displays are great for featuring products on display behind, inviting the viewer to take a closer look. For example, place them in the store front to highlight specific features for certain products.

On OLED displays you can rely as powerful tools for transmitting a message to your audience in a sleek and visually appealing fashion. Their stand-alone no-backlight-required appearance gives off a very futuristic feel. They can pack a punch as a visual component in the more luxurious ends of industries such as retail, hospitality, and beauty.

The aspect of transparency is pretty cool for any viewer observing the display from the front. Even if that transparency doesn’t enhance the message in any way, it provides a visual kick. However, the back of the display makes no attempt to be appealing. As Dave would say, the view from the back essentially looks like looking at the rear of a TV.

When investing in larger transparent displays, keep this in mind. If your transparent displays are going to be mid-air, they’ll naturally need additional support. In this case, perhaps it would be better to avoid hanging displays, or find a better location where very few people will be able to see the display from the back.

When it comes to the content you’ll display in campaigns, images are an important component. Here a different kind of transparency comes into play, but one which might interest you as well but have not found information on elsewhere.

Images in png format are ideal for transparency. Digital signage software makes it a breeze to combine a variety of images and videos with transparent backgrounds by overlapping them. Naturally, you can use this feature even if you don’t have a transparent display. Use the transparency attribute tocombine different visual components seamlessly. Here’s an example of how you could overlay a logo over the principal content in your campaigns without much trouble.

This content creation characteristic will come in handy for transparent displays and is only one of the many OnSign TV offers. You can check out all of them right now and see which ones suit you best after you sign up forOnSign TV for free!

1. Details: length 120mm, width 80mm, thickness 3mm, black color frame with a semi-transparent window for screen (which makes the panel looks totally like a black panel when the screen light is off), silver printed buttons, clear surface, well-polished straight flat edge with chamfer 0.5mm. Welcome to custom your design.

2. Processing: From cutting raw material – glass sheet into little pieces to making physical/heat tempering treatment, the processing procedures are done in our factory. And so is the screen printing step. The production volume reaches 2k – 3k per day. For customized request, that coating anti-fingerprint on the clear surface is workable, this keeps it dirt resistant and fingerprint resistant.

3. Better performance than acrylic glass (acrylic, actually a kind of plastic panel) in yellow resistance ability. The glass panel has a shiny crystal look. Adding a panel of glass to your light switch is just like adding an elegant design to your product, to create the more popular item in market.

The present invention relates generally to refrigerated display cases and refrigerator doors and, more particularly, to a refrigerator door with a transparent LCD panel. BACKGROUND OF THE INVENTION

The invention described herein includes the use of a transparent LCD glass panel as one of the panes in a three-pane unit, such as one used in an insulated glass refrigerator/freezer door.

One of the issues with such a door is supplying power, data and/or communications to the components within the refrigerated display case. Glass refrigerator/freezer doors commonly have a mechanism to supply 120VAC or 240VAC power to the door for anti-sweat heaters. Most stores use a traditional electrical cord. This cord flexes in the cold and suffers from copper conductor fatigue, and insulation cracking. To overcome these weaknesses, solutions have been provided in which the electrical conductors are passed through the hinge pin. By running the conductors concentric with the axis of the hinge pin, flexing and fatigue is minimized, thus improving reliability. The high voltage conductors and associated contacts require appropriate insulation and spacing as dictated by UL and other safety certification organizations. See, for example, U.S. Pat. No. 4,671,582 (referred to herein as the “"582 patent”), issued on Jun. 9, 1987 to Stromquist, et al., the entirety of which is incorporated herein by reference.

Other types of refrigerator/freezer doors also require both power and data. For example, LED light fixtures mounted to the swinging door, LED illuminated marquee signs mounted inside the insulated glass assembly of the door, LCD displays mounted on the door handle, and transparent LCD glass panels with advertising all require both power and data. Most of these products require UL Class 2 low voltage (<60VDC), and many require a data supply, e.g. LCD displays with advertising pictures or videos requiring TCP/IP type data communications.

Generally, the invention is to use a transparent LCD glass panel as one of the panes in a three-pane unit, such as one used in an insulated glass refrigerator/freezer door. With the transparent LCD panel, a consumer can see the media shown on the LCD panel, but can also see inside the display case/refrigerator to view the contents therein. For example, transparent LCD panels are commercially available from Samsung. In a preferred embodiment, the LCD glass panel is used as the center panel. It is within the scope of the present invention to use the LCD glass panel as the inner or outer pane or to add the LCD glass panel as an additional pane. However, in a preferred embodiment, the LCD glass panel needs to be protected from impact and/or moisture damage. Mounting the panel externally may decrease visible transmittance and would also subject the panel to impact by shopping carts. Also, if the store ambient temperature and humidity are not properly controlled, the door can be subject to condensation which may damage the LCD panel or associated electronics. Mounting the panel inside the freezer (adjacent to the food) may cause condensation when the door is opened. Housing the LCD panel inside the hermetically sealed glass unit protects the panel from condensation damage. The associated electronics can also optionally be mounted inside the hermetically sealed glass assembly to protect them from condensation damage. In another embodiment, the electronics can be mounted outside the hermetically sealed glass assembly, such as in the rail of the door.

The door preferably includes the following distinctive features: (1) transparent LCD panel functioning as the center insulating pane of a three-pane low-temp glass freezer door to maximize visible transmittance while maintaining thermal insulating performance; (2) transparent LCD panel mounted between an inner and outer pane of glass to it protect from impact damage; (3) transparent LCD panel mounted inside the hermetically sealed glass unit to protect from moisture damage; (4) mounting the associated electronics, wires, and media player inside the sealed glass unit to protect it from moisture damage or inside the rail of the door; (5) using selectively decorated opaque areas (e.g. screen printing, dot matrix decorating, roller printing, ink jet printing, painting or the like) of the outer or inner pane of glass to hide the circuit boards around the LCD panel perimeter, the wires, and media player hardware of the door assembly, allowing the complete system to be conveniently housed inside the door. The “LCD door” can be used for advertising merchandise, nutritional value, pricing, etc.

In accordance with a first aspect of the present invention there is provided a door assembly that includes a single glass unit having at least first, second and third panels, a front surface, a rear surface, and an outside edge. At least one of the first, second or third panels is a transparent LCD panel on which media can be displayed. The single glass unit also includes a frame that at least partially surrounds the outside edge of the single glass unit, and electronic components in electrical communication with the LCD panel. In a preferred embodiment, the second panel comprises the transparent LCD panel and is positioned between the first and third panels and the first panel is spaced from the second panel by a first spacer and the third panel is spaced from the second panel by a second spacer. The first, second and third panels each have an outside edge and a length and a width. The length and the width of the second panel is smaller than the length and the width of the first and third panels, thereby defining a margin between the outer edge of the second panel and the outer edges of the first and third panels. The first panel is spaced from the third panel by a third spacer that is positioned within the margin.

In a preferred embodiment, the single glass unit includes insulation disposed within the margin and between the first and third panels and the second panel is hermetically sealed between the first and third panels. Furthermore, the first panel includes an outer opaque section and an inner transparent section through which the second panel is visible. In one embodiment, the electronic components for running the LCD panel are disposed between the first and third panels. In another embodiment, the electronic components are positioned in the rail and the rail includes a removable cover for accessing the electronic components. In an embodiment, one of the panels includes an electro-conductive film thereon that is generally clear, wherein when a voltage is applied across a portion of the film, the film becomes opaque. In an embodiment, the electronic components are powered by 24V DC. BRIEF DESCRIPTION OF THE DRAWINGS

FIG. 1 is a perspective view of a series of refrigerated display cases that each include a door assembly with single glass unit having a center LCD panel;

FIG. 2 is a front elevational view of one of the single glass unit having a center LCD panel of FIG. 1 with a portion of the front outer pane cut away to show the electronic components;

FIG. 1 shows a series of refrigerated display case doors 100 that include a three-pane unit, single glass unit or package 10 with a transparent LCD panel 16 associated therewith. FIGS. 2-4 show the single glass unit 10 with front/outer pane 12, rear/inner pane 14 and center transparent LCD panel 16. It will be understood that in FIGS. 2-4 and 8, the outer perimeter or frame 102 of the door 100 is not shown. In a preferred embodiment, the panes are glass. However, any transparent material, such as plastic, can be used.

As shown in FIG. 3, in a preferred embodiment, the single glass unit 10 includes front and rear panes 12 and 14, LCD panel 16, electronic components 18, spacers 20 a, 20 b, 20 c,and insulation 22. In a preferred embodiment, the front and rear panes 12 and 14 include an opaque section 24 that obscures or hides components inside the unit 10. For example, by providing the opaque section 24 (preferably done by screen printing or some other type of coating) on selected areas of one or more of the panes 12 and/or 14, the spacers 20 a, 20 b, 20 cinsulation 22, electronic components 18 and other components can be housed inside the unit 10 (and the door 100) and hidden from view. Thermal insulation 22 may be added in certain areas to maintain the overall thermal performance of the door.

Each panel 12, 14 and 16, has a front and rear surface, For ease of description, these are described herein and depicted in FIG. 4 as surfaces 121, 122, 123, 124, 125 and 126. It will be appreciated by those skilled in the art that in use surface 121 faces the customer and surface 126 faces the interior space of the display case.

In a preferred embodiment, the opaque section 24 on the front and rear panes 12 and 14 (or dot matrix decorating, etc.) is placed on surfaces 122 and 125 to hide the components therein and the margin of the LCD panel, etc. However, this is not a limitation and the opaque section(s) can be placed on any desired surface.

It will be understood that the LCD panel may include a number of different layers or panes of glass/plexiglass or the like laminated to one another. Accordingly, as used herein, the LCD panel can be a single layer or multi-layer panel that includes an LCD screen for playing media. For example, the LCD screen may include a layer of glass adhered thereto to improve strength and reduce flex when the door is slammed. This can add strength to the LCD panel by essentially making it a double laminated panel. In a preferred embodiment, the LCD panel 16 has an aluminum rail therearound.

In a preferred embodiment, as shown in FIG. 3, unit 10 includes at least three different spacers 20 a, 20 band 20 c.Spacer 20 aspans the space between the front and rear panels 12 and 14, spacer 20 bspans the space between the front panel 12 and the LCD panel 16, and spacer 20 cspans the space between the rear panel 14 and the LCD panel 16, as is shown in FIG. 4. It will be understood that the spacers 20 a, 20 band 20 care adhered to a surface of the panel 12, 14 or 16. For example, spacer 20 ais adhered to the inner surfaces of front panel 12 and rear panel 14. In a preferred embodiment, the spacers 20 a, 20 band 20 care made of an elastomeric material. However, this is not a limitation on the present invention. The spacers can be made of other materials, such as a polymer, a metal such as aluminum, etc. The elastomeric material or spacers 20 band 20 csupports and suspends the LCD panel 16 inside the door and between the front and rear panels 12 and 14, thus helping prevent damage from shock and vibration when the door 100 closes. In another embodiment, the spacers 20 a, 20 band 20 ccan be formed as a unit, as shown in FIG. 8 and as shown in U.S. Pat. No. 6,148,563, the entirety of which is incorporated herein by reference. In this embodiment, the front and rear panels 12 and 14 are spaced from the center panel by spacers 20 band 20 c,but they are also connected by spacer 20 a.This essentially forms a single spacer with a detent in the middle for receiving the LCD panel 16.

When incorporating a single glass unit 10 with a transparent LCD panel 16, the door includes components 18 for operation of the LCD screen. As shown in FIGS. 2 and 4, in a preferred embodiment, the LCD panel 16 is smaller (length and width dimensions) than the outer panes 12 and 14. This provides space or a margin 25 around the perimeter of the LCD panel 16 for housing the components 18. For example, the unit 10 or door 100 can include circuit board(s) 26 (labeled A-D board in FIG. 2), wires or cables 28, a media player 30 (that includes a hard drive with memory and appropriate software) and associated connectors and such for providing media and/or power to the LCD panel 16. In another embodiment, the unit 10 can include one or more speakers 29, as shown in FIG. 7. In a preferred embodiment, components 18 are positioned within the margin 25 under the LCD panel 16. However, this is not a limitation on the present invention and the components 18 can be positioned as desired. See, for example, FIG. 7, where the components are positioned in the rail of the door, which is described more fully below.

It will be understood that the single glass unit 10 can be modified as necessary to fit within any type of door to be used in a refrigerated display case or the like. FIG. 5, shows the unit 10 within an exemplary door assembly 100. The door preferably includes a handle 104 to open or close and alternately seal or unseal the interior space of the display case. Typical display cases include numerous other structures for attaching the door(s) to the display case, as well as features for housing wiring, mullions, gaskets and other associated brackets and components that are typically included in refrigerated display cases. These features are well known in the art and will not be discussed in detail herein. An example of such components are discussed in U.S. Pat. Nos. 6,606,832, and 6,606,833 the disclosures of which are incorporated by reference herein in their entireties.

As discussed above, in a preferred embodiment, unit 10 includes a media player 30 for controlling and playing media on the LCD panel 16. Data can be provided to the media player 30 via wires or cables or wirelessly, e.g., Wi-Fi, 802.11:x, etc., as desired (with the appropriate transmitter and/or receiver). In a preferred embodiment, the media player 30 includes a solid-state drive to prevent a spinning hard drive from failing when the door is slammed. However, this is not a limitation on the present invention and a spinning hard drive or other type of drive can also be used. Wireless (or wired) communications with the media player 30 can be used to deliver desired content to be played on the LCD panel 16, e.g, advertising content, nutritional content, special offers, etc. For example, the invention can implement IP addressable communications so an advertiser can remotely feed new data over the Internet. Furthermore, this allows remote monitoring of the health of the hard drive of the media player and associated electronic components.

In a preferred embodiment, the case into which the door 100 is mounted is pre-wired with low-voltage DC power supply, e.g. 12V, 24V, UL Class 2, etc. so that it accepts a transparent LCD door 100 with power through the hinge pin 31, or wired cords near the rotating hinge pin. However, this is not a limitation on the present invention. For example, a high-voltage option can also be implemented. As shown in FIG. 5, insulated electrical conductors and/or wired communications (for the media player 30 and associated components) can be directed through the hinge pin 31 (e.g., via TCP/IP-type Internet communications).

One feature of a preferred embodiment of the invention is to provide an electrical hinge pin 31, similar to the "582 patent hinge pin, but replacing the AC conductors of the "582 patent with low-voltage DC conductors and a data cable. The elimination of the high voltage AC conductors makes more space available in the hinge pin 31 for both the low-voltage DC antisweat heat and powering the electronics, and a data cable, e.g. Cat 5 with TCP/IP type communications. The low voltage conductors (e.g., 24V DC) can be used to power all electronic components, such as the components 18 for the LCD panel 16, heated glass, anti-sweat perimeter heating, etc. In another embodiment, the electrical hinge pin can be omitted and a regular hinge pin can be used. For example, in an outside mount embodiment of the door, the electronic components can be powered by (and data communicated therewith) a cord that does not run through the hinge pin. This type of door may be used, for example, on a self serve case at the end of a check out aisle in a store.

In a preferred embodiment, (and preferably in low-temp applications), an insulating gas, such as argon, xenon or other insulating gas can be used to fill the inner and/or outer cavities 32 between the LCD panel 16 and the front and rear panes 12 and 14, as shown in FIG. 4 (and other voids or cavities within the unit 10). In a preferred embodiment, the gas-filled inner cavities 32 are hermetically sealed (see seal 33 in FIG. 4) to keep from contaminating the transparent LCD panel 16 with dust, residue or outgassing from the outer insulated cavity containing insulation and electronics.

The thickness of the unit 10 can be different for different applications. However, in an exemplary embodiment, the overall thickness of the unit 10 is preferably about 0.125″, with the front and rear panes 12 and 14 being about 0.125″ thick and the center LCD pane 16 being about 0.125″ thick. These dimensions are not a limitation on the present invention.

In a preferred embodiment, panes 12, 14 and 16 are preferably designed to maximize visible light transmission from inside the case to the customer, thereby improving the ability of customers to view display items. However, it is also desirable to minimize the transmission of non-visible light (i.e., ultraviolet and infrared light) through glass unit 10 from outside to inside the case in order to improve thermal performance and to protect items therein. Coolers are a type of refrigerated display case which operate at a temperature of approximately 38° F. Freezers are another type of refrigerated display case which operate below 0° F. When the glass unit 10 of such display cases comes into contact with ambient air, the relatively colder glass unit 10 can cause moisture in the air to condense on the surfaces of the glass unit. Thus, besides the use of the electro-conductive coating described above, it is desirable to use the non-visible wavelengths of light to heat the glass panels, thus reducing or preventing condensation. In a preferred embodiment, the panes 12, 14 and 16 can also include a UV inhibitor, which can help increase the shelf life of products inside. Also, panes 12, 14 and 16 may include low-emissivity heat-reflective coatings to improve overall thermal resistance and/or prevent external condensation. In an embodiment where reflection is an issue, an anti-reflective coating can be applied to any of the panes the glass unit 10.

In a preferred embodiment, the unit 10 includes motion sensor technology, such as a visual recognition camera 36, as shown in FIG. 6. In this embodiment, the media player 30 only plays content on the LCD panel 16, when a person walks by or in front of the unit 10. In an exemplary embodiment, the unit 10 can include software that allows the camera 36, and/or the components thereof, to recognize if a man or a woman is standing in front of the door 100. Therefore, the advertisement or other media played on the LCD panel 16 can be tailored to the specific gender of the person standing in front of the door 100.

In another preferred embodiment, two or more smaller screens can be combined in a matrix to increase the visible display area. For example a 46″ 16:9 standard TV size in a 30″×67″ door leaves a large opaque margin top and bottom. Two smaller adjacent panels would leave more space for visible transmittance. Another way to increase the visible area is to cut down the long side of a larger 16:9 LCD panel such that it better fits the typical 67″ or 75″ vertical height but would otherwise exceed the standard 30″ width.

In another embodiment, a series of doors can be synchronized to display one images or related images on each of the doors, similar to a JumboTron that displays an image or images on a series of synched screens. In this embodiment, a central control unit that is in electrical communication (wired or wirelessly) with electrical components within each door can be used.

Furthermore, the LCD panel does not have to be the center panel. In other embodiments, the LCD panel can be the inside or outside panel. For example, a transparent LCD screen can be adhered or laminated to the outside panel or the inside panel of a triple pane refrigerator door. In another embodiment, the unit 10 can include more than three panels or panes. For example, the LCD panel 16 can be inserted between the first and second or second and third panels in a triple pane refrigerator door.

In a preferred embodiment, a separate pocket is created in the margin of the door outside the hermetic seal of the insulated glass, that would allow access to the media player and related electronic components 18 for service or upgrade. This can be implemented by using an “offset” insulated glass package/unit (e.g. pane number three is smaller than pane number one) to create the pocket to contain the media player or other electronics to allow service. However, the glass package/unit does not have to be offset. In another embodiment, as shown in FIG. 7, the pocket 38 is created or defined in the hollow area made by the rail 106. As shown, the rail 106 can include a cover 40 that is removably attached to the rail 106 by threaded fasteners or the like. The cover 40 can be removed to allow access to the pocket 38 and the electronic components 18 therein, thus allowing repair, upgrade, replacement, etc. In FIG. 7, the pocket 38, cover 40 and components 18 are shown in the top rail 106 of the door 100. However, the pocket 38, cover 40 and components 18 (such as speaker 29) can be mounted in any rail or portion of the frame. In another embodiment, the electronic components for running the LCD panel can be mounted in the display case or refrigerator.

In another preferred embodiment, the unit 10 includes a switchable film or glass 42 disposed or laminated on at least one of the surfaces of the front or rear panels 12 and/or 14, as shown in FIGS. 6 and 8. In a preferred embodiment, the film is disposed on surface five, which is the front surface of the rear panel 14. The panel with the switchable film 42 can be formed by laminating a liquid crystal switchable film thereon or the film can be directly mounted on the panel with a double sided tape, optical glue or the like. In use, a voltage is selectively applied to the film to make it either clear or opaque as desired. In a preferred embodiment, if a voltage is applied to the film, it goes clear and if no voltage is applied it is opaque or frosted. Therefore, in use, if no voltage is applied, images on the clear LCD panel look like a regular television, which helps accentuate the images on the transparent LCD panel and eliminate the distracting contrast of the product in the display case. Then when a voltage is applied, the film goes clear and the product in the case is easier to see. In another embodiment, the film 42 is disposed on the front or center panels. In another embodiment, the film 42 is disposed on another panel, such as a fourth panel. In another embodiment, the single glass unit includes only two panels, one of which is the LCD panel and the other includes the switchable film 42. This type of unit can be used in non-door applications, such as in department store windows, etc. where the window is desirable to be transparent at times and opaque at other times to better see the media on the LCD panel. As will be appreciated by those skilled in the art, appropriate wiring and the like can be associated with the film 42 to supply the voltage. In a preferred embodiment, switchable film 42 is backlit with the display case lighting.

In an embodiment, the door 100 can include a light guide plate (made of glass, plexiglass or the like) that helps illuminate (preferably via LED lighting) the images on the LCD panel. Other types of lighting for LCD panel are also within the scope of the invention.

In another embodiment of the invention, the glass unit may be a laminated glass unit without any space between the panes, as is shown in U.S. Patent Publication No. 2010/0043293, the entirety of which is incorporated herein by reference. Also, the display case may or may not be refrigerated.

Unless the context clearly requires otherwise, throughout the description and the claims, the words “comprise,” “comprising,” and the like are to be construed in an inclusive sense, as opposed to an exclusive or exhaustive sense; that is to say, in the sense of “including, but not limited to.” As used herein, the terms “connected,” “coupled,” or any variant thereof, means any connection or coupling, either direct or indirect, between two or more elements; the coupling of connection between the elements can be physical, logical, or a combination thereof. Additionally, the words “herein,” “above,” “below,” and words of similar import, when used in this application, shall refer to this application as a whole and not to any particular portions of this application. Where the context permits, words in the above Detailed Description of the Preferred Embodiments using the singular or plural number may also include the plural or singular number respectively. The word “or” in reference to a list of two or more items, covers all of the following interpretations of the word: any of the items in the list, all of the items in the list, and any combination of the items in the list.

LCD panelscan be categorized as flat-panel displays. What makes them distinct from other display technologies is the layer of liquid crystal material within. In this thin layer, liquid crystal molecules are aligned between two glass substrates. On the inner surfaces of each of those substrates lie electrodes that control charge carriers like electrons that then interact with the liquid crystals, creating an electric field that runs through them; this, in turn, can change the alignment of the crystals, also changing the overall behavior of the molecules. On the opposite sides of the substrate, polarizers are used to control the levels of light passage, affecting the overall image of the display.

Unlike CRT monitors, LCD monitors cannot illuminate themselves, and so they require a light source: the backlight. This backlight is most frequently made of the well-known LEDs which stand for light-emitting diodes. Sourced from the backlight, light is moved through the back polarizer and back substrate, into the liquid crystals. Now, the light waves can behave in a variety of ways. Backlight used in LCD displays can be LED (Light Emitting Diode) backlight or CCFL (Cold Cathode Fluorescent Lamp) backlight. LED backlights use less power which becomes more popular, while CCFL is lower cost for large size LCD displays such as large LCD TV. Recently, quantum dots technology is used to increase the LCD contrast.

Electrodes are the controlling factors of the liquid crystal behavior, and thus also the light behavior. By conducting or not conducting a current into the crystal layer, the light may or may not be able to pass through the liquid crystals in a manner that will allow passage through the polarizer. Because of this role, electrodes in LCDs are often made of indium tin oxide (ITO). ITO has good conducting properties and can also make for a transparent electrode which is essential to the appearance of displays today.

How the electrodes affect the liquid crystal alignment can vary depending on the method of alignment used (twistednematic,multi-domain,in-planeswitching). For example, twisted nematic liquid crystals are oriented in a twist when no electric field is present which then polarizes the light passing through the layer; when the electrodes apply the field in full, the twist will straighten out, no longer polarizing the light, and so no light passes. In each of these alignment types, the electrodes are placed differently within the structure, altering the properties of the display, such as width of viewing angle, power consumption, and response time. Despite these different alignment methods, the liquid crystal layer’s purpose remains the same: to polarize the light so that the polarized light passes through to the surface of the display. By polarizing the light transmitted from the backlight, the liquid crystal molecules play a role in how much of the light passes through the polarizing filters, whether it be all, none, or a partial amount.

Because of its transparency and thinness, it can be incorporated into LCD module, such as between liquid crystal and backlight, and between touch panel and liquid crystal.

Whether supplying the heater film alone or as part of the module including the laminated cover glass, touch sensor and LCD display Nissha can support. Our project and QA management experience for film touch sensor programs seamlessly extends to the inclusion of optically clear film heater from development through to mass production.

Recently, ‘Liquid crystal display (LCD) vs. organic light-emitting diode (OLED) display: who wins?’ has become a topic of heated debate. In this review, we perform a systematic and comparative study of these two flat panel display technologies. First, we review recent advances in LCDs and OLEDs, including material development, device configuration and system integration. Next we analyze and compare their performances by six key display metrics: response time, contrast ratio, color gamut, lifetime, power efficiency, and panel flexibility. In this section, we focus on two key parameters: motion picture response time (MPRT) and ambient contrast ratio (ACR), which dramatically affect image quality in practical application scenarios. MPRT determines the image blur of a moving picture, and ACR governs the perceived image contrast under ambient lighting conditions. It is intriguing that LCD can achieve comparable or even slightly better MPRT and ACR than OLED, although its response time and contrast ratio are generally perceived to be much inferior to those of OLED. Finally, three future trends are highlighted, including high dynamic range, virtual reality/augmented reality and smart displays with versatile functions.

Display technology has gradually but profoundly shaped the lifestyle of human beings, which is widely recognized as an indispensable part of the modern world

In this review paper, we present recent progress on LCDs and OLEDs regarding materials, device structures to final panel performances. First, in Section II, we briefly describe the device configurations and operation principles of these two technologies. Then, in Section III, we choose six key metrics: response time, contrast ratio, color gamut, lifetime, power efficiency, and panel flexibility, to evaluate LCDs and OLEDs. Their future perspectives are discussed in Section IV, including high dynamic range (HDR), virtual reality/augmented reality (VR/AR) and smart displays with versatile functions.

Liquid crystal (LC) materials do not emit light; therefore, a backlight unit is usually needed (except in reflective displays) to illuminate the display panel. Figure 1 depicts an edge-lit TFT-LCD. The incident LED passes through the light-guide plate and multiple films and is then modulated by the LC layer sandwiched between two crossed polarizers

As summarized in Table 1, these four LCD modes have their own unique features and are used for different applications. For example, TN has the advantages of low cost and high optical efficiency; thus, it is mostly used in wristwatches, signage and laptop computers, for which a wide view is not absolutely necessary. MVA mode is particularly attractive for large TVs because a fast response time, high CR and wide viewing angle are required to display motion pictures. On the other hand, IPS and FFS modes are used in mobile displays, where low power consumption for a long battery life and pressure resistance for touch screens are critical.

Abbreviations: FFS, fringe-field switching; IPS, in-plane switching; LCD, liquid crystal display; MVA, multi-domain vertical alignment; TN, twisted nematic; TV, television.

The basic structure of an OLED display, proposed by Tang and VanSlykeFigure 3a. Electrons and holes are injected from electrodes to organic layers for recombination and light emission; hence, an OLED display is an emissive display, unlike an LCD. Currently, multi-layer structures in OLEDs with different functional materials are commonly used, as shown in Figure 3b. The emitting layer (EML), which is used for light emission, consists of dopant and host materials with high quantum efficiency and high carrier mobility. Hole-transporting layer (HTL) and electron-transporting layer (ETL) between the EML and electrodes bring carriers into the EML for recombination. Hole- and electron-injection layers (HIL and EIL) are inserted between the electrodes and the HTL and ETL interface to facilitate carrier injection from the conductors to the organic layers. When applying voltage to the OLED, electrons and holes supplied from the cathode and anode, respectively, transport to the EML for recombination to give light.

Generally, each layer in an OLED is quite thin, and the total thickness of the whole device is <1 μm (substrates are not included). Thus the OLED is a perfect candidate for flexible displays. For an intrinsic organic material, its carrier mobility (<0.1 cm2 Vs−1) and free carrier concentration (1010 cm−3) are fairly low, limiting the device efficiency. Thus doping technology is commonly used

To evaluate the performance of display devices, several metrics are commonly used, such as response time, CR, color gamut, panel flexibility, viewing angle, resolution density, peak brightness, lifetime, among others. Here we compare LCD and OLED devices based on these metrics one by one.

The last finding is somehow counter to the intuition that a LCD should have a more severe motion picture image blur, as its response time is approximately 1000 × slower than that of an OLED (ms vs. μs). To validate this prediction, Chen et al.

If we want to further suppress image blur to an unnoticeable level (MPRT<2 ms), decreasing the duty ratio (for LCDs, this is the on-time ratio of the backlight, called scanning backlight or blinking backlight) is mostly adopted

As Figure 6 depicts, there are two types of surface reflections. The first one is from a direct light source, i.e., the sun or a light bulb, denoted as A1. Its reflection is fairly specular, and in practice, we can avoid this reflection (i.e., strong glare from direct sun) by simply adjusting the display position or viewing direction. However, the second reflection, denoted as A2, is quite difficult to avoid. It comes from an extended background light source, such as a clear sky or scattered ceiling light. In our analysis, we mainly focus on the second reflection (A2).

To investigate the ACR, we have to clarify the reflectance first. A large TV is often operated by remote control, so touchscreen functionality is not required. As a result, an anti-reflection coating is commonly adopted. Let us assume that the reflectance is 1.2% for both LCD and OLED TVs. For the peak brightness and CR, different TV makers have their own specifications. Here, without losing generality, let us use the following brands as examples for comparison: LCD peak brightness=1200 nits, LCD CR=5000:1 (Sony 75″ X940E LCD TV); OLED peak brightness=600 nits, and OLED CR=infinity (Sony 77″ A1E OLED TV). The obtained ACR for both LCD and OLED TVs is plotted in Figure 7a. As expected, OLEDs have a much higher ACR in the low illuminance region (dark room) but drop sharply as ambient light gets brighter. At 63 lux, OLEDs have the same ACR as LCDs. Beyond 63 lux, LCDs take over. In many countries, 60 lux is the typical lighting condition in a family living room. This implies that LCDs have a higher ACR when the ambient light is brighter than 60 lux, such as in office lighting (320–500 lux) and a living room with the window shades or curtain open. Please note that, in our simulation, we used the real peak brightness of LCDs (1200 nits) and OLEDs (600 nits). In most cases, the displayed contents could vary from black to white. If we consider a typical 50% average picture level (i.e., 600 nits for LCDs vs. 300 nits for OLEDs), then the crossover point drops to 31 lux (not shown here), and LCDs are even more favorable. This is because the on-state brightness plays an important role to the ACR, as Equation (2) shows.

Calculated ACR as a function of different ambient light conditions for LCD and OLED TVs. Here we assume that the LCD peak brightness is 1200 nits and OLED peak brightness is 600 nits, with a surface reflectance of 1.2% for both the LCD and OLED. (a) LCD CR: 5000:1, OLED CR: infinity; (b) LCD CR: 20 000:1, OLED CR: infinity.

Recently, an LCD panel with an in-cell polarizer was proposed to decouple the depolarization effect of the LC layer and color filtersFigure 7b. Now, the crossover point takes place at 16 lux, which continues to favor LCDs.

For mobile displays, such as smartphones, touch functionality is required. Thus the outer surface is often subject to fingerprints, grease and other contaminants. Therefore, only a simple grade AR coating is used, and the total surface reflectance amounts to ~4.4%. Let us use the FFS LCD as an example for comparison with an OLED. The following parameters are used in our simulations: the LCD peak brightness is 600 nits and CR is 2000:1, while the OLED peak brightness is 500 nits and CR is infinity. Figure 8a depicts the calculated results, where the intersection occurs at 107 lux, which corresponds to a very dark overcast day. If the newly proposed structure with an in-cell polarizer is used, the FFS LCD could attain a 3000:1 CRFigure 8b), corresponding to an office building hallway or restroom lighting. For reference, a typical office light is in the range of 320–500 luxFigure 8 depicts, OLEDs have a superior ACR under dark ambient conditions, but this advantage gradually diminishes as the ambient light increases. This was indeed experimentally confirmed by LG Display

Calculated ACR as a function of different ambient light conditions for LCD and OLED smartphones. Reflectance is assumed to be 4.4% for both LCD and OLED. (a) LCD CR: 2000:1, OLED CR: infinity; (b) LCD CR: 3000:1, OLED CR: infinity. (LCD peak brightness: 600 nits; OLED peak brightness: 500 nits).

For conventional LCDs employing a WLED backlight, the yellow spectrum generated by YAG (yttrium aluminum garnet) phosphor is too broad to become highly saturated RGB primary colors, as shown in Figure 9aTable 2. The first choice is the RG-phosphor-converted WLEDFigure 9b, the red and green emission spectra are well separated; still, the green spectrum (generated by β-sialon:Eu2+ phosphor) is fairly broad and red spectrum (generated by K2SiF6:Mn4+ (potassium silicofluoride, KSF) phosphor) is not deep enough, leading to 70%–80% Rec. 2020, depending on the color filters used.

Recently, a new LED technology, called the Vivid Color LED, was demonstratedFigure 9d), which leads to an unprecedented color gamut (~98% Rec. 2020) together with specially designed color filters. Such a color gamut is comparable to that of laser-lit displays but without laser speckles. Moreover, the Vivid Color LED is heavy-metal free and shows good thermal stability. If the efficiency and cost can be further improved, it would be a perfect candidate for an LCD backlight.

As mentioned earlier, TFT LCDs are a fairly mature technology. They can be operated for >10 years without noticeable performance degradation. However, OLEDs are more sensitive to moisture and oxygen than LCDs. Thus their lifetime, especially for blue OLEDs, is still an issue. For mobile displays, this is not a critical issue because the expected usage of a smartphone is approximately 2–3 years. However, for large TVs, a lifetime of >30 000 h (>10 years) has become the normal expectation for consumers.

Here we focus on two types of lifetime: storage and operational. To enable a 10-year storage lifetime, according to the analysis−6 g (m2-day)−1 and 1 × 10−5 cm3 (m2-day)−1, respectively. To achieve these values, organic and/or inorganic thin films have been developed to effectively protect the OLED and lengthen its storage lifetime. Meanwhile, it is compatible to flexible substrates and favors a thinner display profile

Power consumption is equally important as other metrics. For LCDs, power consumption consists of two parts: the backlight and driving electronics. The ratio between these two depends on the display size and resolution density. For a 55″ 4K LCD TV, the backlight occupies approximately 90% of the total power consumption. To make full use of the backlight, a dual brightness enhancement film is commonly embedded to recycle mismatched polarized light

The power efficiency of an OLED is generally limited by the extraction efficiency (ηext~20%). To improve the power efficiency, multiple approaches can be used, such as a microlens array, a corrugated structure with a high refractive index substrateFigure 11 shows the power efficiencies of white, green, red and blue phosphorescent as well as blue fluorescent/TTF OLEDs over time. For OLEDs with fluorescent emitters in the 1980s and 1990s, the power efficiency was limited by the IQE, typically <10 lm W−1(Refs. 41, 114, 115, 116, 117, 118). With the incorporation of phosphorescent emitters in the ~2000 s, the power efficiency was significantly improved owing to the materials and device engineering−1 was demonstrated in 2011 (Ref. 127), which showed a >100 × improvement compared with that of the basic two-layer device proposed in 1987 (1.5 lm W−1 in Ref. 41). A white OLED with a power efficiency >100 lm W−1 was also demonstrated, which was comparable to the power efficiency of a LCD backlight. For red and blue OLEDs, their power efficiencies are generally lower than that of the green OLED due to their lower photopic sensitivity function, and there is a tradeoff between color saturation and power efficiency. Note, we separated the performances of blue phosphorescent and fluorescent/TTF OLEDs. For the blue phosphorescent OLEDs, although the power efficiency can be as high as ~80 lm W−1, the operation lifetime is short and color is sky-blue. For display applications, the blue TTF OLED is the favored choice, with an acceptable lifetime and color but a much lower power efficiency (16 lm W−1) than its phosphorescent counterpartFigure 11 shows.

To compare the power consumption of LCDs and OLEDs with the same resolution density, the displayed contents should be considered as well. In general, OLEDs are more efficient than LCDs for displaying dark images because black pixels consume little power for an emissive display, while LCDs are more efficient than OLEDs at displaying bright images. Currently, a ~65% average picture level is the intersection point between RGB OLEDs and LCDs

Flexible displays have a long history and have been attempted by many companies, but this technology has only recently begun to see commercial implementations for consumer electronics

In addition to the aforementioned six display metrics, other parameters are equally important. For example, high-resolution density has become a standard for all high-end display devices. Currently, LCD is taking the lead in consumer electronic products. Eight-hundred ppi or even >1000 ppi LCDs have already been demonstrated and commercialized, such as in the Sony 5.5″ 4k Smartphone Xperia Z5 Premium. The resolution of RGB OLEDs is limited by the physical dimension of the fine-pitch shadow mask. To compete with LCDs, most OLED displays use the PenTile RGB subpixel matrix scheme

The viewing angle is another important property that defines the viewing experience at large oblique angles, which is quite critical for multi-viewer applications. OLEDs are self-emissive and have an angular distribution that is much broader than that of LCDs. For instance, at a 30° viewing angle, the OLED brightness only decreases by 30%, whereas the LCD brightness decrease exceeds 50%. To widen an LCD’s viewing angle, three options can be used. (1) Remove the brightness-enhancement film in the backlight system. The tradeoff is decreased on-axis brightness

In addition to brightness, color, grayscale and the CR also vary with the viewing angle, known as color shift and gamma shift. In these aspects, LCDs and OLEDs have different mechanisms. For LCDs, they are induced by the anisotropic property of the LC material, which could be compensated for with uniaxial or biaxial films

Cost is another key factor for consumers. LCDs have been the topic of extensive investigation and investment, whereas OLED technology is emerging and its fabrication yield and capability are still far behind LCDs. As a result, the price of OLEDs is about twice as high as that of LCDs, especially for large displays. As more investment is made in OLEDs and more advanced fabrication technology is developed, such as ink-jet printing

Currently, both LCDs and OLEDs are commercialized and compete with each other in almost every display segment. They are basically two different technologies (non-emissive vs. emissive), but as a display, they share quite similar perspectives in the near future. Here we will focus on three aspects: HDR, VR/AR and smart displays with versatile functions.

Both LCD and OLED are HDR-compatib

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey