lcd panel auto-touch factory

If your car or truck factory radio LCD with touchscreen monitor needs replaced then we provide some of the best replacement car touch LCD screen replacement parts available on the market today. As is Factory Radio Parts standard: all of our car touchscreen repair kits are developed for both ease of use and functionality – so you can get your tunes blasting again in no time!

Automotive onboard panel display due to high technical specifications, good profit, has always been the LCD panel display suppliers-related manufacturers of a competitive place. In the first half of 2020, the global auto industry was in a depressed market due to coVID-19, lockdowns, and factory shutdowns. However, as economic activity gradually restarts and auto factories resume production, the industry is very positive about the recovery of the automotive panel display market in 2021. Among them, the trend of electric vehicle growth is more concerned.

At present, Taiwan LCD panel display manufacturers, including Au, Qunchuang, and Caijing, have set up the automotive panel market, and cooperate with the first-line big manufacturers to continuously and stably deliver products. Tpk-ky, a big manufacturer of touch panels, is the supplier of Tesla, a big manufacturer of electric cars. Gs-ky has also been working in the Japanese and European car markets for many years.

On the panel component manufacturers’ side, polarized light-sheet da chang MMG is currently focusing on the electric vehicle battery three-layer isolation film (PP/PE/PP). In addition to having started shipping to Chinese customers last year, it has also recently made gains in the Japanese market. Dachang Ruiyi in recent years began to put into the vehicle panel backlight module, this year also entered the Supply chain in Europe and the United States.

Au has cultivated the automotive panel market for many years, and its TFT-LCD panel has entered into the supply chain of many European brands and also introduced products into electric locomotives. According to statistics, AU has accounted for 13%-15% of the global automotive panel market this year.

At present, the company is more active in the research and development of Micro LED display technology. It is optimistic that Micro LED has such characteristics as high brightness, high reliability, fast response time, and no need for a backlight, which can replace a large number of LCD screens in the future and become the mainstream of vehicle display technology.

Following the launch of au’s first 12.1-inch full-color active Micro LED panel in 2019, au will add two new production lines of automotive panel modules in the second quarter of 2020. It is reported that the European and American automobile manufacturers have been contacted so far, and it is expected that Micro LED panel screens will be adopted by automobile manufacturers in 2022 at the earliest.

Qunchuang also spared no effort in the layout of the automotive panel market. At present, its main customers include first-tier European car manufacturers and Tesla, a major ELECTRIC car manufacturer in the United States. According to statistics, it accounts for about 10% of the global automotive panel market this year.

In addition to the original TFT LCD technology, the company has also started to introduce Mini LED technology into vehicle panels in recent two years. It is reported that the company has obtained orders from European and American automobile manufacturers, and is also expected to ship in large quantities in 2022.

At the same time, the group of the vehicle and continued toward the larger screen product development, has announced the introduction of corning laser automatic large size glass laser cutting system of science and technology, main is to be used in manufacturing advanced automotive touch panel, providing customers with high design flexibility, high precision cutting, process more optimized for the touch panel.

Having previously focused on small and medium-sized mobile devices, especially mobile phones, the company has recently accelerated its shift to niche applications such as industrial controls, medical care, and automotive applications. Among them, vehicle panels have been successfully produced in the past two years. Currently, vehicle panels account for about 30% of its revenue.

In the beginning, there were many customers in the supply chain of Chinese automobile manufacturers. Later, it gradually entered the supply chain of Japanese automobile manufacturers and other international automobile manufacturers. Affected by the us-China trade conflict, Caijing moved a vehicle panel module production line from China’s Nanjing plant back to Taiwan’s Nanke Plant in 2019.

Ling Ju’s largest shareholder is Japanese topographies with a stake of nearly 35 percent. Its main production lines are located in Taoyuan, Miaoli, Hsinchu, and Kunshan. In recent years, the company has also focused on the development of niche application panels for automotive, industrial control, medical, home appliances, etc.

Among them, automotive panels now account for about 30% of the revenue. The existing product line includes instrument panels, temperature control panels, head-up displays, etc., and it continues to launch the sample submission certification of new products. It is expected to see new product benefits as soon as 2021.

Tpk-ky, a major touch panel manufacturer, has cooperated with Tesla, a major American electric vehicle manufacturer, for many years. Although the orders for pen and mobile device applications are large and the proportion of touch panels in TPK-KY’s revenue is low so far, the company is still quite optimistic about the future development of electric vehicles.

Gis-ky cultivates the automotive touch panel market with many years of experience. A few years ago, it launched the automotive curved touch panel products with 3D fully fitting technology. However, due to the large orders of other product lines such as mobile devices, and the addition of on-screen fingerprint identification and LAPTOP LCD module NB LCM products recently, the proportion of vehicle touch panel revenue has been low so far.

At present, GS-KY’s application of vehicle touch panel products includes the center console, indoor light, instrument panel, driver’s seatback control, etc., promising the future development of the vehicle touch screen. In recent years, it has expanded the business of customers in Japan and Europe simultaneously.

Ruiyi used to focus on IT application panel backlight module products. In recent years, due to the increasing penetration of OLED panels in the mobile phone screen market, the company has strengthened its layout in other application fields such as automotive and regards automotive panel backlight module products as one of the business priorities in the next few years.

Due to the successive certification of panel customers and first-tier automobile manufacturers, it is estimated that Ruiyi’s vehicle product shipments in 2020 are expected to grow significantly compared with 2019, and even have the opportunity to challenge double, and the revenue contribution of vehicle products in the future is also expected to gradually increase.

Despite the recent strong rebound in large LCD panel prices, it is estimated that large LCD panel display manufacturers could return to profit as soon as the end of this year. But consumer applications, with their short life cycles and demand that often come and go quickly, remain wary.

For automobile LCD display panel suppliers and display groups related vendors, including industrial control, medical treatment, public displays, automotive displays, and so on niche products, while customers certification for a long time, but due to long product life cycle, high technology content, good profits relative also is still the major panel factory and monitor the supply chain manufacturer Mohican.

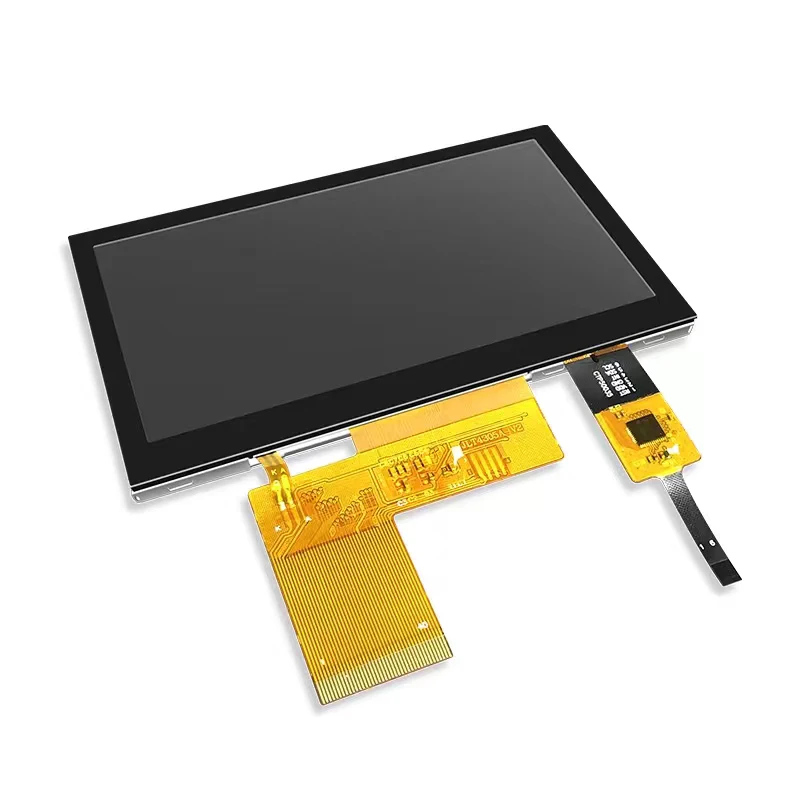

Founded in 2008, Shenzhen Feixin Intelligent Co., Ltd. is a comprehensive private high-tech enterprise specializing in LED display modules, touch screens, complete machines, R&D, production and sales. Quality control team. At present, the parts developed and produced are widely used in automotive electronics, liquid crystal displays, mobile phones, PDA display panels, various meters and other digital cameras, camcorders and other products have been successfully sold to North America, Europe, South Korea, Taiwan, Hong Kong and other countries and regions except China Outside mainland customers.

In the LCD module industry, it is the largest production plant in Shenzhen. We have a larger and more advanced factory than Foxconn, and a dust-free workshop with a thousand people. Our four major factories are located in Shenzhen, Hunan, Anshan and Huizhou, with production capacity up to 100K/day. Provide you with productivity advantages

Founded in 2008, Shenzhen Feixin Intelligent Co., Ltd. is a comprehensive private high-tech enterprise specializing in LED display modules, touch screens, complete machines, R&D, production and sales. Quality control team. At present, the parts developed and produced are widely used in automotive electronics, liquid crystal displays, mobile phones, PDA display panels, various meters and other digital cameras, camcorders and other products have been successfully sold to North America, Europe, South Korea, Taiwan, Hong Kong and other countries and regions except China Outside mainland customers.

In the LCD module industry, it is the largest production plant in Shenzhen. We have a larger and more advanced factory than Foxconn, and a dust-free workshop with a thousand people. Our four major factories are located in Shenzhen, Hunan, Anshan and Huizhou, with production capacity up to 100K/day. Provide you with productivity advantages

LCD displays in cars have been flat, rectangular and low resolution since the beginning. However, as the cockpit becomes a smart mobile digital assistant, there is increased need for bigger, higher-resolution, more immersive displays. Next-generation cockpit displays are curved and offer high resolution at much larger sizes than current displays. Visteon is one of the largest suppliers of automotive displays to the industry and has multiple years of experience in critical aspects of automotive use cases, such as head impact safety, long life, extreme temperatures, vibrations and reflectivity.

The ACD-110D has been designed to provide the best performance for many applications. Its compact and slim profile is well suited in working locations where space is at a premium. Complying with the power management regulations of VESA DPMS, the LCD monitor is extremely energy efficient and power saving while displaying sharper, more brilliant, crisper and flicker-free images. Other features include low radiation and near zero electromagnetic fields emissions.

Fully compatible with a PC, the LCD monitor supports DDC1/DDC2B-compliant “Plug & Play” specification, making installation a breeze. The On-screen Display menu provides user a user-friendly interface to make right adjustment for most optimal display.

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

Good quality comes to start with; service is foremost; organization is cooperation" is our enterprise philosophy which is regularly observed and pursued by our firm for Industrial Tft-Lcd Panel, Multi Touch Display, Sunlight Readable Lcd Module, Industrial Touch Displays,Tft Clear Screen. We, with fantastic passion and faithfulness, are willing to offer you with best services and striding forward with you to make a bright foreseeable future. The product will supply to all over the world, such as Europe, America, Australia,Bogota, The Swiss,Salt Lake City, UK.Our mission is "Provide Goods with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Although in Android, the process may vary from device to device, the rule of thumb is to open the overview panel, either by pressing the overview button on the bottom right. If you have gesture navigation on, you can either swipe up from the bottom of your screen, hold and then release. If you have a two-button navigation you simply swipe up from the middle of your screen. After that, depending on your device, you either swipe up or press the "Close all" button.

You could, of course, pay a third-party repair shop to reseat your screen in the connectors for you to see if it fixes the problem, which would be cheaper than a whole new panel.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey