anet a8 lcd screen made in china

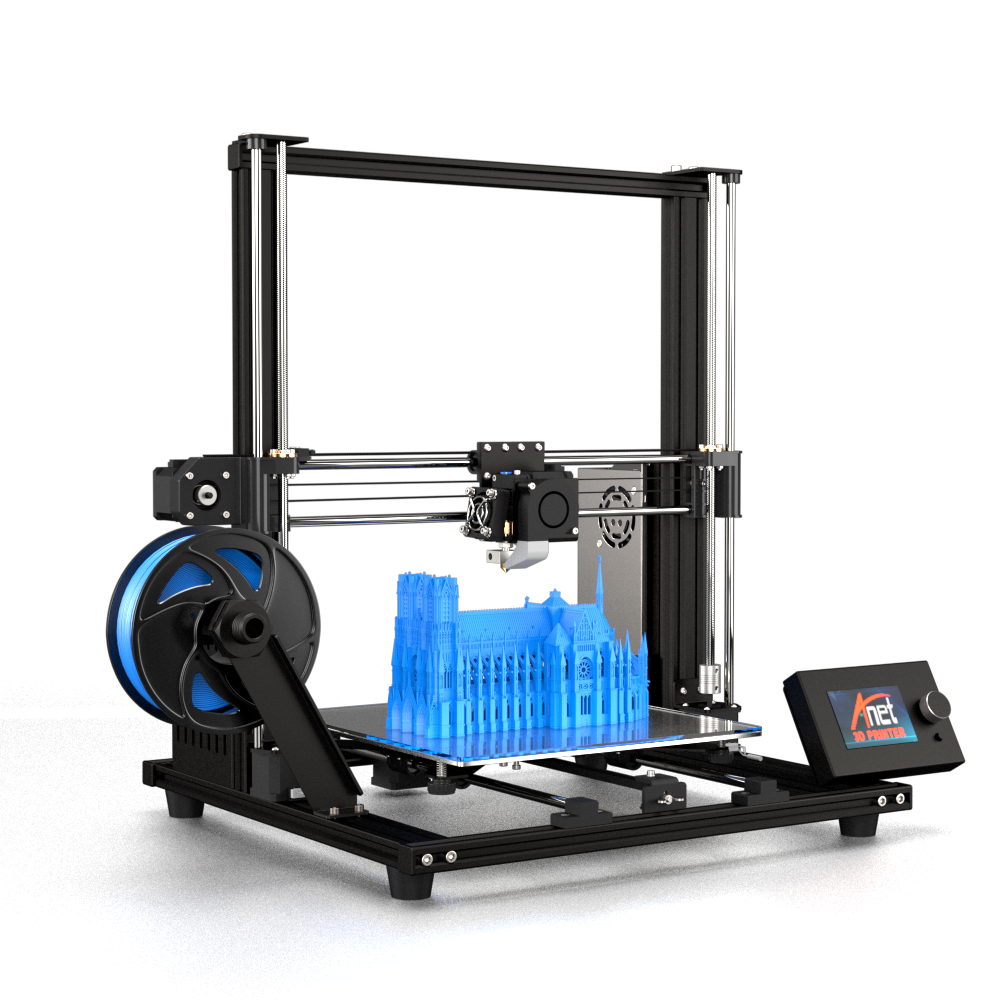

The Anet A8 3D printer was very popular with the community. 2.5 years ago a 3D printer was still something “really new” and the price was right. With the Anet A6 a fine update followed, but then it became relatively quiet around Anet. The competition, especially Creality3D, simply produced better models. Now the 3D printer series returns with the Anet A8 Plus. Does the Anet A8 Plus manage to continue the success of its predecessor?

On the paper there are some big upgrades and the screws were screwed where the predecessor often had something to complain about. The acrylic frame has been abandoned for some time and aluminium profiles are used ( since the Anet E10). The Direct Drive extruder is probably a small unique selling point – it is rather rare in China 3D printers.

The LCD screen is attached to the holder by magnets and is removable, so to speak – no idea what this is good for. I would rather prefer a firmly screwed on display. Why? Because despite the magnets, the display still has plenty of room to move. It wobbles, sits crooked with time and vibrates during printing. Annoying.

The Anet A8 Plus definitely can’t build on the success of its older brothers. The attempt to eradicate old weaknesses and “inspire” the competition was not successful. Instead of following in the footsteps of the competition, they rely on components of inferior quality. The Anet A8 Plus is a 3D printer that is simply not up to date. Due to the pre-programmed cable clutter, the construction is particularly nerve-racking for beginners.

Despite the aluminium frame, it also feels very rickety, which is also noticeable during printing – and the print image also suffers as a result. In my opinion, the wrong corners and ends were saved here and instead extras were used that are nice, but not necessary (see detachable LCD screen).

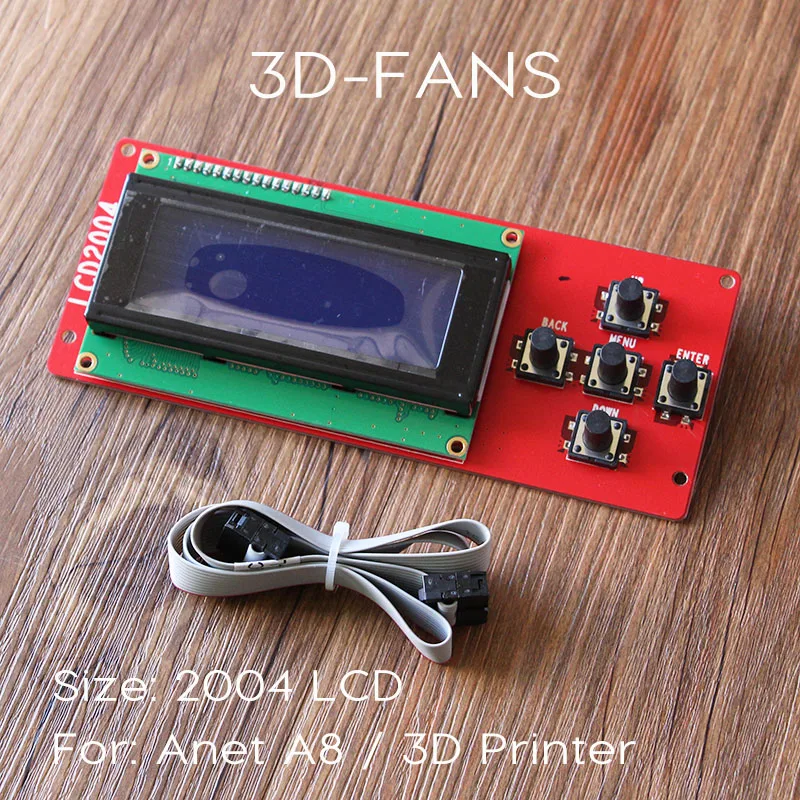

The problem is that the Anet A8 display of the A8 (5 button 2004 LCD) uses analog signals for the buttons (and it has no SD card reader). This means that there is no way to connect the LCD to the EXP connectors (they only have digital connections) as the buttons would not work. The question is where the AUX2 port is located on your board. Once you find that, you can connect the display through that header. The alternative is not using the buttons and only connect the LCD. But the most easy solution for you would be to spend another few bucks and buy a proper Discount Full Graphic Smart Controller](https://reprap.org/wiki/RepRapDiscount_Full_Graphic_Smart_Controller), these are available on those typical auction sites and Chinese suppliers under 10 $, and as a bonus you get an SD card reader.

This time, we will tell you about Anet, one of the leading Chinese manufacturers of popular inexpensive 3D printers used by both beginners and advanced makers — by sophisticated users and those who are only getting familiar with 3D printing. Find out the history of the company and its products in the given article.

Founded in 2015 in China, Shenzhen Anet Technology is a high-tech enterprise that designs, manufactures and markets 3D printers and accessories. Anet primarily produces desktop printers using FDM and DLP technologies, which are employed for domestic and training purposes. The production volume is 300–500 thousand units per year. Anet products are represented in more than 80 countries, there being customer service centers in addition to stores themselves.

At the annual MEI 2017 Awards in Guangzhou (Manufacturing Excellence & Innovation), Shenzhen Anet Technology"s nominee for Easy DIY 3D Printer Kit (E10 and E12 printers) was recognized as a leader in the 3D printer industry.

The MEI Summit, hosted by Made-in-China.com, aims to support innovations in local production and take the Chinese quality standards to a new level. Anet products were selected and nominated for a prize out of 4,309 applications.

The company also takes part in international exhibitions of high technologies. In 2019, the Chinese manufacturer introduced its Anet N4 DLP printer and Anet A10 delta printer at the 31st exhibition of information and communication technologies "Svyaz" in Moscow.

As we mentioned above, the main focus of Anet production is printers based on FDM technology. Such devices print with melted plastic, which forms layers superimposed on one another.

Many Anet A8 owners recommend installing a MOS transistor (metal oxide semiconductor) on the motherboard. In addition to improving fire safety, the transistor makes it possible to install a second power supply unit (PSU), which significantly reduces the time required to heat the bed.

This model is similar in characteristics to the Anet A8 printer. The latter has a bigger design, but their print area is approximately the same. The A6 also features a horizontal extruder position and a more vibration-resistant frame, which contributes to more stable printing. To learn more about the differences between these models, watch the video:

Another type of photopolymer printing is the use of LCD technology, with the light from the array of diodes passing through the LCD panel, which forms the projection of a layer.

Tomas Aceytuno, an owner of the Anet A8 printer, is directly involved in his wife’s new hobby — customization of Blythe dolls and making clothes for them. She needs small parts that Tomas prints with his 3D printer.

With the help of A8, Tomas printed a number of spare accessories such as a hinge enabling to rotate the doll’s head, doll stands, mannequins for clothes, hangers, shoe soles, clothing buttons, earrings, and so on.

The Australian decorator Luke Towan has printed a miniature version of his house by means of the Anet N4 3D printer. To do this, Luke made accurate measurements of the objects using a tape measure. The scale of the 3D model of the house is 1:87.

As already mentioned, the popular Anet A8 can be modified. Tomas Aceytuno, for example, installed a laser module on the printer. To do this, he needed a support and one cable, with which he connected the module to the motherboard.

Anet is a modern manufacturer of affordable 3D printers, which are well suited for training, home and garage workshops, small business. They have, to be sure, some common drawbacks inherent in all low-cost devices, but they also have significant advantages over minor printers from unknown manufacturers: the availability of service and parts, warranty, a large community of enthusiastic users who are always ready to help with advice on sites and forums.

Are you looking for a quality 3D printer that doesn’t break the bank? If so, the Anet A8 is perfect for you! It is one of the most affordable on the market, but it still offers high-quality prints. In this review, we will take a closer look at this 3D printer and discuss its features and benefits. We will also check on the lifehacks as well as reviews from the users to help you decide if it is the right choice for you.

The Anet A8 is a great machine for those who are looking to get into the world of additive manufacturing without spending a lot of money. It offers a great build volume, and it comes with everything you need to get started printing. The only downside is that it doesn’t have some of the bells and whistles that more expensive printers have, but it is still a great machine for the price.

It has a large build volume. The A800 has a build area of 220 x 220 x 240 mm (or about 11,000 cubic centimeters). That’s big enough to print most things you’ll want to make. It comes with everything you need to get started.

It’s easy to upgrade. As mentioned before, because the A800 is based on an open-source design, it’s easy to find and install upgrades for it. The community is great. There are lots of people online who are happy to help with any problems you might have.

So if you’re looking for a great value desktop printer, then it’s definitely worth considering. With its relatively medium-sized build volume, heated bed, and easy-to-use controls once assembled, this Anet A8 offers everything you need to get started

Positive Reviews On Anet A8Makers’ Muse, a Youtube channel with more than 900k subscribers in his review says that “Anet A8 is big, cheap, and won’t catch fire.

A user called Supersailor who bought the 3D printer on Amazon says that “Anet A8 is a good entry 3D printer and the updates are very helpful too. He continued to say that the version that he received was updated, unlike the one he had seen online. The frame was redesigned and it was more sturdy and didn’t require any strengthening. Though he had to modify a few things like the X and Y linear bearings. The filament holder also required a little modification in order to hold onto the filament.

Liz Miller, Founder of Learnrobotics.org in her article “Before you buy Anet A8 read this!” says that the machine is a great starting point for those who are tight on budget and they would like to learn how a 3D printer works generally.

Amstudio with more than 215k subscribers says that Anet A8 is cheap, has many safety upgrades and there is a large community and support for many users. They say also that it’s a great 3D printer for those who like Diy, tinkering, and building. You can check out their video review (https://www.youtube.com/watch?v=DeeQp-Cc5Yc)

Negative Reviews of Anet A8One of the most popular complaints is that the printer isn’t very durable. The frame is known to warp and crack over time, which can cause all sorts of problems down the line. A user on Facebook, for example, complained that his frame was flimsy and he was considering doing upgrades.

This means that if you want your Anet A8 to last, you’ll need to be extra careful with it – and that’s not always easy when you’re dealing with delicate electronics.Another common complaint is that the software can be a bit finicky. Getting everything set up just right can take some trial and error, and even then things might not work as smoothly as you’d like. This can be frustrating for users who are used to more user-friendly interfaces. For example, a user on Reddit complained that he was having trouble getting Anet A8 work well with Cura Slicer. And someone recommended upgrading the firmware from the Standard version to Malin. Also, another user complained that he was having challenges updating to Cura 3.5 and the printer kept scratching over the previous layers he was forced to cancel the print and it only worked when he downgraded to Cura 3.2.

Another major drawback of Anet A8 is the time taken to assemble. It’s a complex 3D printer that takes really a lot of time to get everything working well and running. Almost everyone who has reviewed this machine has at one point mentioned this issue. Machinerycritic also mentions that it takes around 10-12 hours to assemble the machine.

Heating issues – Many users have reported issues with the heating element in these printers, which can lead to prints being ruined or taking a long time to complete. This is a major problem for those who need to print quickly or consistently. Some users have reported that they see “def” on the screen and the bed and extruder temperatures don’t increase. To troubleshoot and solve this issue, you can check out Gearbest article.

Noisy operation – The Anet A8 printers are notoriously noisy, meaning that they can be a distraction in busy households or workplaces. For example, a user on Thingiverse said that he is very happy with his machine, but the only challenge is that it’s noisy. This can be a serious issue for those who need to concentrate while printing.

Finally, some users have had issues with customer service. While most Anet A8 owners seem to be happy with the company’s response time and willingness to help, there are a few reports of less-than-satisfactory experiences for example a user rated the printer one star on Trustpilot because he didn’t get any support. This is something to keep in mind if you run into any problems with your printer.

All in all, the Anet A8 seems to be a decent entry-level printer – but it’s not without its flaws. If you’re considering buying one, make sure you do your research and read as many reviews as possible before making a decision. That way, you can be sure you’re getting the best possible product for your needs.

Here are our top three Anet A lifehacks:The first lifehack is all about saving time when it comes to leveling your bed. Rather than fiddling around with those little knobs, try this method instead: take a sheet of paper and place it under your extruder nozzle. Slowly lower the nozzle until it just barely touches the paper, then mark where the nozzle is touching with a pencil. Now move the paper until it’s under one of the bed’s adjustment screws, and turn the screw until the mark you made is in the center of the adjusting screw. Repeat this process for all four corners of your bed and you’ll be done in no time!

We hope you enjoyed these lifehacks and that they help you get the most out of your printer. Do you have any favorite Anet A8 hacks of your own? Share them with us in the comments section!

Anet A8 is a pretty famous DIY FDM 3D printer from a Chinese manufacturer Anet 3D. This machine became one of the first affordable printers on the market, quickly becoming a choice for many newcomers. Despite being released a long time ago, Anet A8 is still on the market surprisingly withstanding competition from newer machines. Is it worth purchasing though? Let’s find out.

When Anet A8 first appeared on the market, a lot of enthusiasts purchased it thanks to the affordable cost of the kit. However, the low machine price was achieved due to cutting corners here and there resulting in first versions not only requiring a lot of upgrades and attention but sometimes being downright unsafe. The main concerning factor at the time was the power cord issue causing a fire hazard, which is in combination low-quality motherboard and unstable printing bed turned some users off the Anet A8. Additionally, when purchasing the kit from Chinese suppliers and resellers, some people ended with a different model, A6, falsely advertised as A8.

The information in regards to all troubles with A8 is easy to find and access, though, people still purchase this kit. And many are able to get pretty decent prints with it as well. Anet A8, undoubtedly, requires love from the very first day of buying it. Starting from building the printer from scratch through a bit messy videos from the manufacturer to making upgrades to accommodate for a wobbly frame. In no way this is ready from the box printer.

But there are bright sides to Anet A8. The manufacturer was quick to make changes to the printer resolving some issues from the first versions. That includes upgrading to an aluminum plate under a heating bed (which was acrylic and prone to warping) with metal rails on two sides. Additionally, later orders included a different motherboard and had changes to power cords and supply (though still no “off” button). These changes went unannounced and have no special mark on the printer’s model, however, by default A8 machines now are shipped with these newer parts. And the price for Anet A8 kit dropped even lower.

One of the great advantages of A8 is being an open system, meaning that with a bit of work the printer can be adjusted to preferences or needs in terms of software and structure. And some of the first upgrades for better performance can actually be 3D printed on the A8 itself. Alternatively, some users purchase A8 as a source of parts, which they build a slightly different printer with, upgrading from light and prone to wobbling acrylic frame to a metal one.

This one is a bit advanced upgrade that will require you to purchase additional bits. However, due to A8 infamous power supply, you should consider monitoring the voltage and current.

4.Copy the Arduino\Hardware folder to the Arduino installed location (Default: C:\Program Files (x86)\Arduino) from the extracted Anet A8 board definition

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey