holley 3.5 in lcd touch screen free sample

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

Did the unthinkable happen to your original Terminator X / X-Max 3.5-inch Touchscreen LCD Display? EFI System Pro has you covered! We"ve got Terminator X Touch Screen LCD Controllers in stock. Genuine Holley product with full Holley warranty.

Set up ECU Datalogging, Download Datalogs to SD Card, Upload and Download Global Folders via SD Card, Update ECU Firmware and Adjust Rev Limiters 1 and 2

Contains latest V4 software (software version 4.0 Build 110). The compatible firmware (firmware version 4.0 Build 110) is included in the software installation. Changes include updates to run Holley EFI Coyote VVT Module, Drive-By-Wire updates, and other items. For specifics, the V4 Revision log.

Holley EFI V5 Build 171 Complete File SetHolley EFI V5 Build 171 Complete File Set - Include Software/Firmware and all Digital Dash or Handheld Firmware. Updated Canned and Custom Ignition Types.

Holley EFI ReloadPM InstallerIt is recommended that all Touch Screen users that purchased a Holley EFI touch screen before June 2011, and experience a battery drain over 2-3 weeks, install this update. See "Touch Screen Update" instructions.

Holley EFI Touch Screen UpdateIt is recommended that all Touch Screen users that purchased a Holley EFI touch screen before June 2011, and experience a battery drain over 2-3 weeks, install this update. Download these instructions.

This website is using a security service to protect itself from online attacks. The action you just performed triggered the security solution. There are several actions that could trigger this block including submitting a certain word or phrase, a SQL command or malformed data.

High Impedance Injector Drivers will safely power most Stock LS injectors, and Holley EFI Injectors. Injector support chart provided in the instructions (Will not control Low Impedance Injectors)

All of the new Terminator X Max systems utilize the Bosch LSU 4.9 wideband to relay AFR information to the ECU for accurate reading and precise tuning control.

On-Board 1bar MAP sensor, is perfect for N/A or Nitrous engine combos. If your combination requires a 2+Bar, we recommend GM 12592525, and our adapter part number 558-416.

4 Inputs – 12v, Ground, 5v, and Frequency, for things such as additional pressure sensors, or activation triggers for nitrous activation, or a trans brake

On-Board Diagnostic LEDS for: ECU Power – Engine Run – Wideband Status – TPS Calibration – Crank Signal –Cam Signal. Allow you to identify any Critical engine issues at a glance

The included 3.5" Touchscreen Handheld contains a calibration wizard, that allows you to quickly build a base tune for any LS engine. Additionally the handheld provides internal data-logging and a fully customizable gauge display.

Plug and play compatible with more Holley EFI accessories such as; analog style gauges, shift lights, various modules, and coming soon, 12.3" digital dash support!

Includes: 24x LS Engine Main Harness - EV6 Injector Harness - 4L60E/4L80E Transmission Control Harness - Terminator X MAX ECU - ECU Main Power Harness - Bosch LSU 4.9 Wideband Oxygen Sensor - Input/Output Harness - and assorted vacuum adapters.

2 CONTENTS Quick Start Guide... 4 Package Contents... 4 Mounting... 4 Connectors... 5 CAN1/Power... 5 CAN Adapter Harness... 5 Making Adjustments... 6 Home Screen... 7 Tuning... 7 Basic Tuning... 7 Basic Fuel... 8 Fuel Learn Basic Idle Spark Drive By Wire Transmission System Tuning Outputs Engine Setup Ignition Setup Transmission Advanced Tuning Advanced Fuel Closed Loop Adv. Learn Adv. Idle Monitor Multi-gauge Monitors Diagnostics Dash Setup Channels Scaling File ECU Overview: ECU Globals: ECU Data Logging:

4 QUICK START GUIDE A CAN/power harness is supplied with the 3.5 TSLCD. Connect the black wire to negative and the white wire to a switched +12V circuit. Connect the harness from the CAN connector on the vehicles main harness to the 3.5 TSLCD using the supplied 4 CAN/Power extension Once all connections have been made, the Holley EFI 3.5 Touch Screen LCD may be powered up. After a brief initial loading sequence the gauge display will appear PACKAGE CONTENTS MOUNTING The 3.5 TSLCD comes with a sleeve that can be mounted in the vehicle with the included double-sided foam tape. 4

5 CONNECTORS CAN1/POWER A 4 pin Mizu-P25 male receptacle connector is used to connect main power and to a Holley EFI. The dual connector allows the product ot be connected to multiple devices on the CAN bus. CAN ADAPTER HARNESS 271R1075A CAN ADAPTER HARNESS used to connect switched +12V ignition power (white wire) and ground (black wire) to the dash, as well as for connecting to the main harness CAN connector. 5

6 MAKING ADJUSTMENTS Slider Bar: Slide the bar left or right with the stylus, or use the right and left arrow keys for fine adjustment List: Use the scroll bar on the right hand side of the screen to view all list entries. Touch the desired list item and click OK to make a selection. Radio Button: Touch the desired list item to select it. On Screen Prompts: Follow the on screen text and use buttons at the bottom of the screen to continue or confirm. Graph: Digitally: Selecting this option enables slider bar adjustment of individual data points on the graph or the entire curve. Graphically: Selecting this option enables single point or whole curve adjustment. A stylus may be used to select and drag data on the graph screen. 6

7 Entire Curve: Selecting this will lock all the data points together allowing the entire curve to be shifted up or down Point by Point: Selecting this will allow point by point curve adjustment for fine tuning. Live Data 1 & 2: This will enable live telemetry on the graph screen making fine tuning easier. HOME SCREEN The Home screen contains icons which will navigate to different functional features of the 3.5 Touch Screen. These features will be discussed in detail throughout this manual. Home Screen TUNING The Holley 3.5 Touch Screen LCD facilitates laptop-free tuning changes to help optimize mileage, drivability, and performance. Tuning is categorized by Basic Tuning, System Tuning and Advanced Tuning. BASIC TUNING From the HOME MENU, select TUNING, and BASIC. There are six areas you can modify, BASIC FUEL, FUEL LEARN, BASIC IDLE, SPARK, DRIVE BY WIRE, and TRANSMISSION. These are reviewed below. 7

8 BASIC FUEL Selecting BASIC FUEL brings up the following menu: TARGET AFR: Allows changes to the Target Air/Fuel ratio at idle, cruise, and wide open throttle. The following are typical values and some tuning notes. Idle Air/Fuel Ratio Typically between 13.5 and Engines with larger cams may need a richer setting for smoothest idle. Cruise Air/Fuel Ratio Typically between 13.5 and Engines with larger cams may need a richer setting for smoothest operation. Wide Open Throttle Air/Fuel Ratio (WOT) Typically between 12.0 and Running richer may reduce power. Running leaner may reduce power or cause potential engine damage. NOTE: The Target Air/Fuel setting between IDLE, CRUISE, and WOT is blended together automatically. Consequently, the air/fuel you see on the MONITOR screen, may not be exactly what you set for the settings. Changing these settings raises or lowers the curve of that specific area. 8

9 ACCELERATION ENRICHMENT: Changes the accelerator pump function of the fuel injection. Raising the number increases the amount of fuel added when the pedal is pushed. Lowering the number decreases the amount of fuel added when the pedal is pushed. It is highly recommended NOT to change this until the ECU is allowed to perform self-tuning. FUEL PRIME: Fuel prime is an option that is enabled by default in all of the base calibrations. The fuel prime function injects a small shot of fuel into the intake manifold when the ignition is turned on, wetting the intake and allowing the engine to start much quicker. The amount of fuel is based on the engine temperature and how long it was since the engine previously ran. This amount of fuel can be increased or decreased by changing the Percent value. If the engine seems flooded reduce this value, if the engine seems to want more fuel, increase it. Experiment for best results. NOTE: This only injects fuel once at key-on, and will not do it again until the engine has run. This fuel prime occurs ½ of a second after key-on. If you quickly turn the ignition key without waiting for ½ a second, the prime will not occur and it may take longer for the engine to start. 9

10 FUEL LEARN LEARN ENABLE / DISABLE: The LEARN Enable / Disable menu turns the Self Tuning On and Off. If enabled, self-tuning is performed. Learning should be enabled when an engine is just started and the tuning process is occurring. After the vehicle is driven under various operating conditions, and is running well, it is advised to disable learning, OR slow the Learn Speed to Slow. LEARN SPEED: This parameter adjusts how fast the learning process occurs. In the beginning with a new tune it should be set to Fast. After the vehicle is driven under various operating conditions, and is running well, it is advised to disable learning, OR slow the Learn Speed to Slow. 10

11 BASIC IDLE Selecting BASIC IDLE allows you to change the Target Hot Engine Idle Speed. This should be adjusted to your desired idle RPM. Values between rpm are typical. Larger camshafts or aftermarket torque converters may require a slightly higher value to maintain proper idle quality while in gear. SPARK All Holley base tunes contain timing curves that will provide adequate engine operation, however the ignition timing at idle, cruise, and wide open throttle can be adjusted independently from each other to compensate for geographical and climate extremes. The following are typical values for each: Idle Timing degrees is typically used at idle. The larger the camshaft, the more timing is usually used. Cruise Timing degrees is typically used when cruising for optimal fuel economy. Wide Open Throttle Timing (WOT) WOT timing is typically between degrees. NOTE: Too much timing can cause pre-ignition that can damage an engine. Be cautious when tuning. NOTE: The actual timing between IDLE, CRUISE, and WOT is blended together automatically. Consequently, the timing you see on the MONITOR screen, may not be exactly what you set for these settings. Changing these settings raises or lowers the curve of that specific area. 11

12 DRIVE BY WIRE Holley Drive By Wire throttle capability is designed to work with specific throttle bodies and recommended pedal assemblies. If using the 3.5 Touch Screen in conjunction with a Holley Terminator EFI kit, be sure to read and follow all instructions regarding Drive By Wire throttle body operation in your kit s installation manual. PEDAL VS THROTTLE: The Pedal vs. Throttle Position table is the primary method of tuning a Drive By Wire throttle body system. The Pedal Position represents the position of the accelerator pedal. The user can adjust the Throttle Position to change based on the pedal position. This allows the user to increase or decrease throttle body position (engine airflow) to tailor the responsiveness of the engine. It can allow for an overly-large throttle body to have good driving manners or a small throttle body to be very responsive. 12

13 TRANSMISSION Selecting TRANSMISSION brings up the following menu. There are five areas you can modify; SHIFTS, WOT SHIFTS, TCC PARAMS, TCC (UN)LOCK, and LINE PRESSURE. These are reviewed below. SHIFTS Each Up-shift and Down-shift can be completely configured by selecting Shifts from the transmission menu. Refer to the Making Adjustments section of this document for instructions on how to modify these curves. 13

14 WIDE OPEN THROTTLE SHIFTS (WOT) Use this menu to choose the RPM at which the transmission will upshift at WOT. Each gear change may be adjusted independent of the others. TORQUE CONVERTER CLUTCH (TCC) PARAMETERS Contains parameters that tune TCC activation and deactivation. Minimum RPM to Enable TCC - Minimum engine speed at which the TCC will apply. This value can be adjusted so that engines with large camshafts do not hesitate surge if the TCC is applied at too low of an engine speed. RPM to Disable TCC - Used to unlock the TCC once it is locked. The Lock and Unlock values should not be too close together, or they will continuously lock and unlock. Applications with high stall torque converters will typically need RPM or more between these values. Maximum TPS TCC - Throttle position value when the TCC will unlock. Most lockup torque converters do not have a clutch designed to lock up when higher power is being applied. It is best to unlock the converter under moderate to hard acceleration. Typically TPS values should be between 25-50%. TCC Disable - When enabled, the TCC will never lock up. 14

15 TCC (UN)LOCK These parameters work in addition to the TCC Parameters by offering additional tuning based on vehicle speed. This keeps the TCC from locking up during around-town driving if it is not desired. The Lock values should always be higher than the Unlock values. Adjustments to these can be done by using the graph. NOTE: See instructions for changing data in the GRAPH screen in the Making Adjustments section. LINE PRESSURE Tune the line pressure vs. TPS or MAP for each gear. A lower duty cycle (moving towards 0%) increases line pressure with 0% providing maximum line pressure applied. Values above 60% typically result in a line pressure too low for any throttle position. 15

16 SYSTEM TUNING From the HOME MENU, select TUNING, and SYSTEM. There are four areas you can modify; OUTPUTS, ENGINE SETUP, IGNITION SETUP, AND TRANSMISSION. OUTPUTS The OUTPUT screen allows for the Fan #1 and Fan #2 ON and OFF temperatures to be adjusted. The ON temp needs to always be a higher value than the OFF temp. Use a difference of at least 5 degrees so they aren t cycling excessively. In Terminator Kits these are ground outputs that should be wired to trigger the fan relays. NEVER wire them directly to the fans! The AC Disable value is a TPS value above which a 12 volt output is sent out to deactivate the air conditioning compressor at wide open throttle. Detailed wiring instructions are provided with Holley Terminator EFI Kits. 16

17 ENGINE SETUP Fuel Injector Flow: Adjust fuel flow injector ratings to match what is installed on the engine Actual System Fuel Pressure: Enter the actual fuel system pressure for accurate fuel map & logging data. Wide Band O2 Sensor Type: Selects the type of wide band oxygen sensor used. If the software selection does not match the sensor being used damage to the WBO2 sensor will occur. Progressive TBI Enable/Disable: This should be for all single blade style throttle bodies. TBI Secondary Blend: This should be set to 0% on all single blade style throttle bodies. 17

18 IGNITION SETUP TRANSMISSION Selecting TRANSMISSION brings up the following menu. There are two areas you can modify; TRANS SETUP and SPEED CALC. These are reviewed below. TRANS SETUP Transmission RPM: If this RPM is exceeded when in manual shift mode, the transmission will upshift automatically. If a manual downshift is performed, and this RPM will be exceeded, the downshift will not be allowed. This value should be slightly higher than the WOT shift points. 18

19 SPEED CALC Four pieces of information will need to be entered via the 3.5 handheld to attain proper speedometer calibration when using Holley transmission control Tire Diameter From 10.0 to 70.0 inches (Example 26.4) Rear Gear Ratio From 0.50 to 9.99 (Example 3.73) Speedometer Output Enabled or Disabled Pulses Per Rotation (PPM) Typically this value is 1 on GM overdrive transmissions 19

20 ADVANCED TUNING From the HOME MENU, select TUNING, and ADVANCED. There are four areas you can modify; ADV FUEL, CLOSED LOOP, ADV. LEARN, AND ADV. IDLE. These are reviewed below. The Advanced Tuning areas typically won t ever be needed to be changed. However, after getting used to the TERMINATOR EFI system, there may be some fine tuning of various parameters that you d like to perform. ADVANCED FUEL Coolant Enrichment: Coolant enrichment is similar to the choke on a carburetor. Adjustments are made as a percentage of the base map from 100% to 150%. 100% would mean no additional fuel is being added by the Coolant Enrichment, 110% would mean that an additional 10% of fuel is being added to the base fuel map which will decay back to 100% in relation to actual engine coolant temperature. Load Based Acceleration Enrichment: This parameter provides another way of adding fuel when the accelerator is depressed. It adds fuel depending on how fast the MAP sensor reading changes (detects a change in engine load). There is typically no need to adjust this parameter except possibly under some extreme conditions of vehicles that are heavy and under-powered. Adjustment values are in pounds of fuel per hour (pph) and should initially be adjusted in increments of 5-10 pph Cranking Fuel: This dictates how much fuel is injected when the engine is cranking and is dependent on coolant temperature. Changing this value offsets the entire curve at all temperatures. Adjustment values are in pounds of fuel per hour (pph) and should initially be adjusted in increments of 5 pph. Afterstart Fuel: The afterstart parameter is fuel that is added for a short time immediately after an engine starts. This value varies depending on engine temperature. Changing this value offsets the entire curve at all temperatures. Adjustments are made as a percentage of the base map from 75% to 200%, 100% would mean no additional fuel is being added, 110% would mean that an additional 10% of fuel is being added to the base fuel map, and 85% would mean that 15% of fuel is being taken away from the base map. All selections will decay back to 100% over a predetermined amount of time. 20

21 CLOSED LOOP CLOSED LOOP OPERATION relies on WBO2 sensor readings. The Holley EFI system uses these readings to analyze real time running conditions. The data obtained by the ECU is then used trim fuel flow to achieve the targeted air fuel ratio (AFR). Choosing CLOSED LOOP from the ADVANCED TUNING menu will allow you to modify four areas of the CLOSED LOOP operation. Closed Loop Enable/Disable: This menu enables or disables closed loop operation. There is typically no reason to turn off closed loop operation unless you suspect an oxygen sensor problem and want to disable the sensor. Note: Self-Tuning requires closed loop operation to function. Closed Loop Limit: The maximum percentage the ECU is allowed to deviate (+/-) from the base fuel calibration in order to maintain the commanded target air fuel ratio. This is set to 100% by default and under most circumstances should not need to be changed. Closed Loop Speed: This is the speed (gain) at which closed loop operation occurs. This can be set to five levels, 1, 2, 3, 4, or 5. 3 is the base setting and should be good for most applications. 4 or 5 is typically not used as the closed loop speed may be too excessive for certain applications. If the oxygen sensor is installed far back in the exhaust (more than 1 foot back from the collector in long tube headers), a value of 1 or 2 may be needed. Open Loop Below This: This setting is usually zero. If an extremely large camshaft is used (specs only typically found on race camshafts), the overlap sometimes causes a false lean reading at low RPM. In these cases, it may be required to put in a value of RPM so the system operates open loop below this RPM setting. 21

22 ADV. LEARN Choosing ADVANCED LEARN will allow you to modify the LEARN COMPENSATION LIMITS. This value is set to 100% by default, and should remain there until ample driving time and tuning has occurred. The LEARN COMPENSATION LIMIT is a parameter that ECU is allowed to work within when making changes to the fuel map based upon CLOSED LOOP operation. Unlike the CLOSED LOOP LIMIT which is a set parameter for commanded changes to actual fuel flow based upon the O2 sensor reading, LEARN COMPENSATION LIMITS are the percentage of change that is allowed to actually be saved as a modifier to the fuel map. ADV. IDLE The ADVANCED IDLE parameters adjust specific characteristics of how the idle air control motor functions on engine decel and startup. Selecting ADVANCED IDLE brings up the following menu: 22

23 IAC RAMPDOWN The Idle Air Control (IAC) motor is a stepper motor located in the throttle body that controls the idle speed of the engine by metering air. It also operates during engine cranking and when the engine returns back to idle. The following settings can adjust how that functions. The IAC moves from a position of 0% (fully closed, no air added) to 100% (fully open, maximum air flow). NOTE: Contact Holley Tech Support if you have any questions regarding IAC settings. Selecting IAC RAMPDOWN brings up the following menu with four choices, IAC HOLD POSITION, IAC RAMP DECAY, IAC RAMP START, and IAC KICK. These are reviewed below: IAC Hold Position: This is the position the IAC motor will hold or freeze at when the TPS moves above idle (when TPS becomes greater than 0%). If it is too high, the engine RPM will hang and not return to idle. IAC Ramp Decay: This is the time (in seconds) it takes for the IAC to decay from the IAC Hold Position back to a 0% position. It is a linear decay. IAC Ramp Start (RPM above idle): This value is the RPM added to the target idle speed that the IAC will automatically start to ramp back down to idle. If this is too low, the engine RPM will hang and not return to idle. IAC Kick: The IAC Kick provides a temporary increase in IAC position to keep engine the RPM from dropping. Typically this is used in conjunction with an A/C system keep the engine speed from dipping as the compressor cycles on and off. 23

24 IAC SPEED This menu is used to select the type of IAC motor application that is being used. This selection drives the background parameters that control the IAC motor. These parameters have been fine tuned for each of these applications, eliminating the need for the user to perform further modifications IAC STARTUP These parameters control the position of the IAC when the engine is cranking and immediately after it starts. Selecting IAC STARTUP brings up the following menu with three choices, IAC PARKED POSITION (CRANKING), IAC STARTUP HOLD TIME, and IAC STARTUP DECAY TIME. IAC Parked Position (Cranking): This is the position the IAC motor will be at during cranking and immediately after the engine starts. If it is too high, the engine will be at too high of an RPM once it starts. Too low and poor starting will result. Note that this is a temperature based table. The percentage value changed in the handheld offsets this entire curve. IAC Startup Hold Time: This is the amount of time that the IAC will remain at the IAC Parked Position. IAC Startup Decay Time: This is the amount of time for the IAC to decay from the IAC Parked Position back to its Target Idle position. It is a linear decay. 24

25 IDLE SPARK Idle spark is a feature active only when the ECU is controlling timing. When enabled, the ECU modifies commanded timing at idle to help maintain the target idle speed. NOTE: This feature should be disabled when checking base timing with a timing light! 25

26 MONITOR Choose MONITOR from the HOME screen to access live telemetry and customizable gauge screen options. MULTI-GAUGE Sensors: Manifold Absolute Pressure (MAP), Coolant Temperature (CTS), Throttle Position (TPS), AFR Left, Engine RPM (analog), Battery Voltage, Ignition Timing, Manifold Air Temperature (MAT), Fuel Pressure, Engine RPM (digital), and Fuel Injector Duty Cycle. Air/Fuel Ratio: AFR Left, Target AFR, AFR Right, Closed Loop Compensation, Fuel Learn, Closed Loop Status, Engine RPM (analog), Learn Status, Fuel Injector Pulse Width, Engine RPM (digital), and Oil Pressure. Outputs: Fan #1, Fan#2, AC Shutdown, CTS, Engine RPM (analog), IAC Position, AFR Left, Battery Voltage, Fuel Pressure, Engine RPM (digital), Oil Pressure. Drive by Wire: TPS, Pedal Position, TB Position, TB TPS #1, Engine RPM (analog), Pedal TPS1, TB TPS #2, Pedal TPS2, Brake Pedal, Engine RPM (digital), MAP. Transmission: Gear, Engine RPM (digital), Line Pressure, TCC Duty, Engine RPM (analog), TCC Lockup, Line Temp, Input Shaft Speed, TPS, Speed, Fuel Economy. Dash 1, 2, & 3: See the Dash Setup section Sample Multi-Gauge Screen 26

27 MONITORS Idle: Engine RPM, TPS, IAC Position, AFR Left, Ignition Timing Learn: Fuel Learn Status, Fuel Learn Percent, Closed Loop Compensation, Target AFR, AFR Left Closed Loop: Closed Loop Status, Closed Loop Compensation, Target AFR, AFR Left, Fuel Learn Status Sensors: MAP, TPS, MAT, CTS, Battery Voltage Fuel: Engine RPM, AFR Left, Injector Pulse Width, CL Comp, Injector Duty Cycle Misc: Oil Pressure, Fuel Pressure, Fan #1 Status, Fan #2 Status, AC Shutdown Status Drive by Wire: Gas Pedal Position, TB TPS #1, TB TPS #2, Pedal TPS #1, Pedal TPS #2, TB Position, Brake Pedal Position Transmission: Gear, Speed, Line Pressure, Line Temperature, TCC Duty Cycle, TCC Lockup Status, Input Shaft Speed Sample Monitor Screens DIAGNOSTICS Channels displayed are: AFR Left, AFR Right, MAP, TPS, MAT, CTS Sample Diagnostics Screen 27

28 DASH SETUP Up to three (3) Custom gauge layouts can be created on the 3.5 Touch Screen. Follow these steps to configure: Step 1: Choose Dash Setup from the Multi-Gauge screen Step 2: Choose the Dash number to be configured Step 3: Select Change Layout Step 4: Choose the desired layout *Previews of the layout are shown at the bottom of the screen in this example Layout #5 has nine gauges Step 5: Select the individual gauge to be configured Step 6: Select the Channel to be displayed 28

29 Step 7: Select the gauge style Step 8: Save your configuration CHANNELS SCALING Each HEFI channel displayed by the 3.5 Touch Screen can be configured to have caution and warning indicators. To do this, choose Channel Scaling from the MONITOR menu. Cautions will display as Yellow and Warnings will display as RED when using the Multi-Gauge screens. 29

30 FILE Choose FILE from the HOME screen to access ECU and 3.5 touch screen information. This is also where ECU logging and Global Folder transfer menus are located. ECU OVERVIEW: Information specific to the engine and ECU configuration is shown here, these include the name of the current global folder, transmission type, ignition input type, WBO2 type, throttle body type, fuel system type, and ECU firmware version. Note that this menu is view only no information can be changed. Any changes to engine or transmission setup must be done through the TUNING or WIZARDS menu. 30

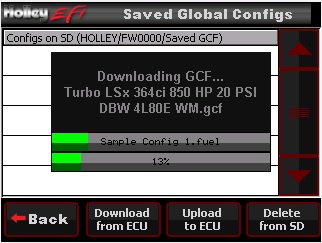

31 ECU GLOBALS: This menu will list any global folders that have been saved to the SD card. It will also allow you to download a global folder from the ECU to the SD card so that it may be opened on any Windows based PC with free Holley EFI software installed. Software may be downloaded at Global Folders List Global Folder Upload to ECU from SD Card Upload Status Screen Global Folder Download to SD Card Status Screen 31

32 ECU DATA LOGGING: Holley HP and Dominator systems come standard with powerful data logging capabilities. Logging can be stopped and started via the 3.5 Handheld. The sampling rate is adjustable from 1 to 100 samples per second and can be changed by selecting Setup. Typically a high sampling rate is used for drag racing and a lower rate may be used for something such as road racing. Choosing Files in the DATA LOGGING menu will display all logs contained within the ECU s memory, from here any file may be saved to the SD card and viewed through the Holley EFI PC software. ECU HARDWARE/FIRMWARE (HW/FW): Use this menu to update ECU Firmware. Also includes ECU data including serial number, date code, firmware version, and profile number. 32

33 Contains calibration options for the 3.5 Handheld LOCAL SETUP: TOUCH CALIBRATE The touch screen may be recalibrated by following the on screen prompts. LOCAL INFO Displays device and firmware information for the 3.5 Handheld. LOCAL OPTIONS By selecting Restore screens on startup the 3.5 Handheld will revert to the last screen used prior to powering off. 33

34 V3 FIRMWARE If you are using V3 Holley software, the firmware within the 3.5 touch screen must be updated for proper functionality. If this warning screen is displayed, choose Upgrade device FW To upgrade from the Local Info Screen Choose Upgrade device FW V3 Firmware is preloaded in the FW3000 Directory Select the firmware and select OK to update the 3.5 NOTE: 3.5 FUNCTIONALITY WILL BE LOCKED IF THE ECU AND TOUCH SCREEN FIRMWARE DO NOT MACTCH. UNLESS YOUR 3.5 TOUCH SCREEN IS LOCKED AND SHOWING THE WARNING MESSAGE ABOVE, PLEASE DISREGARD THE V3 FIRMWARE SECTION OF THIS INSTRUCTION MANUAL! 34

35 WIZARDS GCF WIZARD The GCF Wizard is a base calibration selection tool used with Holley Terminator EFI kits. This function is not active with the touch screen. TPS WIZARD A TPS Autoset may be performed via the 3.5 eliminating the need to use the HEFI software. Step 1: Select TPS Autoset Step 2 Step 3 Step 4: Select Done 35

Take control of your LS engine with Terminator X! Don"t settle for a junkyard ECU with a cumbersome tuning interface when you can have complete control of your engine, self-learning fuel strategies and the proven, race-winning technology of Holley EFI at a budget-friendly price! Terminator X features real-time fuel learn, high impedance injector drivers, an integrated 1bar MAP sensor, and 4 programmable inputs and outputs. The inputs and outputs are ideal for electric fans, boost control solenoids, progressive nitrous control, and much more. Terminator X comes fully loaded with base maps for common LS engine combinations to get you out of the garage and on the road/track fast. The 3.5" touch screen LCD handheld contains an easy to use calibration wizard as well as tuning and gauge display functions. Also included is Holley EFI"s industry-leading, easy to use software suite that allows full laptop access for advanced users. Whether you are building a budget beater or a boosted race car, Terminator X has the features and technology you need at a price that won"t break the bank!

High Impedance Injector Drivers will safely power most Stock LS injectors, and Holley EFI Injectors. Injector support chart provided in the instructions (Will not control Low Impedance Injectors)

All of the new Terminator X systems utilize the Bosch LSU 4.9 wideband to relay AFR information to the ECU for accurate reading and precise tuning control.

4 Inputs – 12v, Ground, 5v, and Frequency, for things such as additional pressure sensors, or activation triggers for nitrous activation, or a trans brake

On-Board Diagnostic LEDS for: ECU Power – Engine Run – Wideband Status – TPS Calibration – Crank Signal –Cam Signal. Allow you to identify any Critical engine issues at a glance

Advanced Tables – 4x 1D Tables, 1x 1D per Gear Table, 4x 2D Tables, 1x 2D per Gear Table, can be used for any custom tables you can dream up, such as Flex Fuel Sensor Offset Table, or a custom fuel or oil pressure safety!adjustable through included 3.5” f

The included 3.5" Touchscreen Handheld contains a calibration wizard, that allows you to quickly build a base tune for any LS engine. Additionally the handheld provides internal data-logging and a fully customizable gauge display.

Plug and play compatible with more Holley EFI accessories such as; analog style gauges, shift lights, various modules, and coming soon, 12.3" digital dash support!

Includes: 24x LS Engine Main Harness - Multec 2 Injector Harness - Terminator X ECU - ECU Main Power Harness - Bosch LSU 4.9 Wideband Oxygen Sensor - Input/Output Harness - and assorted vacuum adapters.

Terminator X and X Max Coyote systems supports Ford Coyote platform with Ti-VCT. Terminator X features real-time fuel learn, high impedance injector drivers, integrated 1bar MAP sensor, and 4 programmable inputs and outputs. These are ideal for electric fans, boost control solenoids, progressive nitrous control, and much more. Terminator X ECU comes fully loaded with base maps for common Coyote engine combinations to get you out of the garage and on the road/track fast. The included 3.5" LCD touch screen handheld contains an easy to use calibration wizard as well as tuning and gauge display functions. Included with Terminator X is Holley EFI"s industry leading support, easy to use software suite that allows full laptop access/compatibility for advance users. Whether you"re building a budget beater or full on race car, Terminator X has the industry leading features and technology you need at a price that won"t break the bank.

Set up ECU Datalogging, Download Datalogs to SD Card, Upload and Download Global Folders via SD Card, Update ECU Firmware and Adjust Rev Limiters 1 and 2

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey