tft display construction quotation

There are different components of a TFT displays that can be modified to create a custom color LCD. Some of the modifications are not too expensive, while others can be cost prohibitive. We will cover some of the main options available and their estimated cost when customizing a TFT display module.

Note: If you need a color LCD module, but do not need video or dot matrix (Graphical) capabilities, I would suggest using a lower cost alternative such as FSC*(Field Sequential Color display) aka known as a TN color display. A second option for a lower cost and much lower power requirement would be a custom segmented display module with color overlays.

This is by far the most expensive component of the TFT module to customize. There are industry standard glass sizes for TFT’s. The list includes, but is not limited to, 2.8 inch, 3.5 inch, 5.7 inch, 7 inch, 10.2 inch and larger. If you can design your product to make use of these standard sizes, then do it. If you need a unique size, say a something between a 2.8 inch and 3.5 inch, you may be forced to invest in a custom glass size. We have seen quotes for custom glass sizes for TFT run between $100,000 dollars to $150,000 dollars. Not a minor investment for most companies.

A TFT LCD display with a modified PCB, is still considered a custom color TFT. Modification costs to customize the PCB is an estimated $400 to $1,200 one-time tooling fee. The unit cost of the TFT display, with a modified PCB will be slightly higher than the cost of the TFT with a standard PCB.

Many products that incorporate a custom color LCD display will contain a touch screen or touch panel. These can be modified to meet a customer’s particular size for an estimated tooling cost of $3,000 to $4,000.

* COG (Chip on Glass) FSC is a new type of technology and not recommended at this time. The most stable type of FSC construction at this time is a COB (Chip on Board)

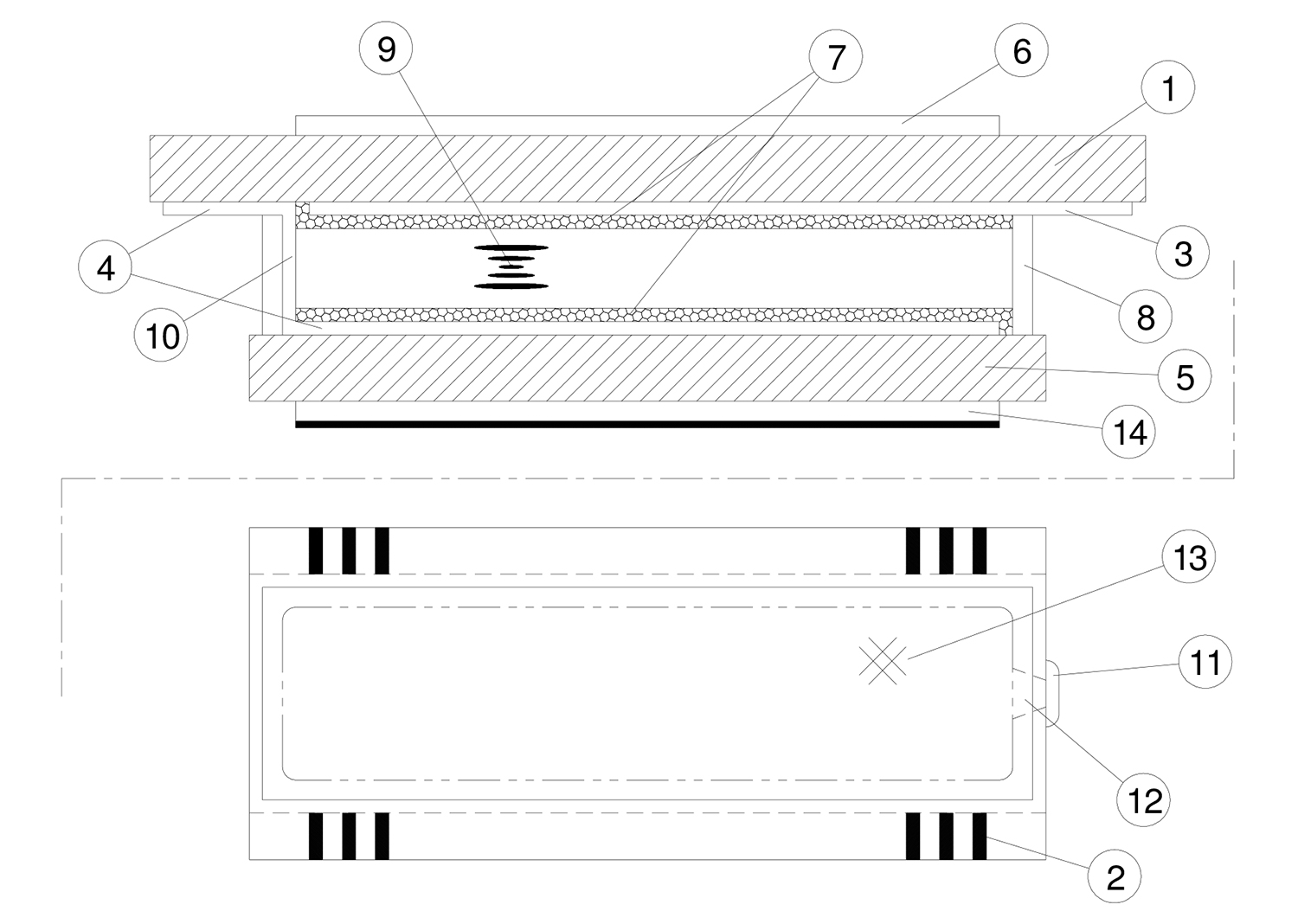

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

This premium LCD TFT display provides high visibility, and versatile construction with Multi-domain vertical alignment (MVA) technology. The 480x272 resolution TFT display allows wide viewing up to 75° from any direction. This 24-bit display is RoHS compliant and offers high contrast images with RGB interface and a 4-wire resistive touch panel.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

This 320x240 resolution LCD TFT is a standard display with 8-bit parallel interface and a 12:00 optimal view. This Liquid Crystal Display has a built-in SSD1963 controller. It is RoHS compliant and has a 4-wire resistive touchscreen.

Choose from a wide selection of interface options or talk to our experts to select the best one for your project. We can incorporate HDMI, USB, SPI, VGA and more into your display to achieve your design goals.

Equip your display with a custom cut cover glass to improve durability. Choose from a variety of cover glass thicknesses and get optical bonding to protect against moisture and debris.

We are changing our TFT part numbers to have them better describe the parts being ordered. The change should be complete for all TFT modules shipping within the next six months.

This graphic display module is a 2.4" diagonal, full color TFT. Suitable for embedded applications, it is low-power, uses a white LED backlight, and has an integrated touch panel which has its connection brought out to the main TAB connector for the display.

It has an on-board controller and 3v single voltage for supply and logic (backlight not included), so you can easily use any modern microcontroller to interface with this display. It uses an 8 or 16 bit parallel interface, specified via connections to the display.

The connector on the CFAF240320K-024T-TS is a flex tail mated with a "COG" (chip on glass) display construction. This style of connector is designed to be soldered directly to corresponding pads on your PCB by using a hot-bar soldering machine. High volume contract manufacturers will be familiar with this type of construction and its assembly methods. There are hot-bar soldering machines made that are designed for prototype, rework or repair work of TAB connections.

Keywords: departments in a Taiwanese high-tech company, which is a top global producer of TFT-LCD equipment.

TFT-LCD industry The cross-fold validation method is applied to measure model performance, reliability, and prediction

The first impression of a display device is based on its design, may generate a good cost assessment via teamwork, professionals

ranges from simple displays in watches to complex technologies medium-sized enterprises in Taiwan. Thus, this experience and

in computers. More than 500 million displays for televisions and project knowledge is hard to retain, resulting in such problems as

were cathode ray tubes (CRTs) in 1999. However, more than 60% The TFT-LCD industry, promoted by Taiwan’s government in

of displays are now flat panels (e.g., liquid crystal displays (LCDs), the Two Trillion Twin Stars plan, has developed rapidly in recent

plasma screens). The global market for panels, which was worth years. The TFT-LCD industry is second only to the semiconductor

2011 (ITIS, 2008). Therefore, thin-film transistor-LCDs (TFT-LCDs) production involves hundreds of complex processes. Each panel

(Menozzi et al., 2001), as TFT-LCDs have excellent features such as production lines requiring diverse manufacturing equipment with

vessels (Caputo and Pelagagge, 2008), building construction little information is available, requires sufficient knowledge and

knowledge of the TFT-LCD manufacturing process. By applying operations, or activities (PMI, 2004). Activity-based costing (ABC),

construction. After consulting experienced engineers of the high- correlation coefficient R0 , were used as comparison criteria. The

machines. The manufacturing processes include TFT, CF, LCD, and where n is the number of validation data, Yi is the equipment

8. Manufacturing process (TFT, CF, LCD, LCM) Dummy (D9, D10, D11) X8 String

terms of single techniques and MAER. costs for equipment used to manufacture TFT-LCDs. Field inter-

timely manner, thereby leading to organizational losses. AI-based techniques for estimating cost of developing TFT-LCD

TFT-LCD panels are currently a global trend and users have forecasting. Civil Engineering and Environmental Systems 22, 71–81.

PMs of TFT-LCD manufacturing equipment an effective and De Barcelos Tronto, I.F., Simoes Da Silva, J.D., Sant’Anna, N., 2007. Comparison of

environmental protection, are adopted, or new manufacturing prediction of total construction costs. Construction Management and

Albright, S.C., Winston, W., Zappe, C.J., 2006. Data Analysis & Decision Making with sourcing process–The case study of Taiwan’s TFT-LCD industry. International

ment 42, 2573–2579. Proceedings of the 12th International Display Workshops in Conjunction with

International Journal of Production Research 36, 883–908. Kim, G.-H., An, S.-H., Kang, K.-I., 2004. Comparison of construction cost estimating

Baykasoglu, A., Kaplanoglu, V., 2008. Application of activity-based costing to a land Kim, K.R., 2007. Laser microfabrications for next-generation flat panel display.

Information & Management 34, 33–40. Lin, J.T., Chen, T.-L., Lin, Y.-T., 2009. Critical material planning for TFT-LCD

Lowe, D.J., Emsley, M.W., Harding, A., 2006. Predicting construction cost using PIDA, 2008. Photonics Industry & Technology Development Association (PIDA),

multiple regression techniques. Journal of Construction Engineering and available online at website /http://www.pida.org.twS, accessed 7/30/2008.

Mendes, E., Mosley, N., Counsell, S., 2002. The application of case-based reasoning Sabnis, R.W., 1999. Color filter technology for liquid crystal displays. Displays 20,

performance. Displays 22, 79–85. Smith, J.R., 2005. LCD Modules, Programming the PIC Microcontroller with

environments. Concurrency Computation Practice and Experience 19, ontology to support construction cost estimating. Cambridge Journals 17,

Manufacturing Technology 13, 618–629. assemble-to-order manufacturing: an illustration on TFT-LCD manufacturing.

Pardo, P.J., Pe!rez, A.L., Suero, M.I., 2004. Validity of TFT-LCD displays for colour metal parts using multiple regression and artificial neural networks: A case

vision deficiency research and diagnosis. Displays 25, 159–163. study. International Journal of Production Economics 111, 484–492.

Park, N.K., Yoo, S.I., 2009. Evaluation of TFT-LCD defects based on human visual Witten, I.H., Frank, E., 2005. Data Mining: Practical Machine Learning Tools and

We supply optimum quality 12 INCH TFT with A/D Card facility which is procured from established vendors across the world. Our auto display cards find its applications in medical instruments, for variousread more...

Recent trend shows that buyers now prefer colour display & demand for colour tft is increasing rapidly. evolute has already geared up to meet this demand from the industry. It has wide varieties of tft panels from 2. 8" ~19" & can support customers with various makes/ brands from japan, taiwan & china.

The cView Series : Mil-Grade TFT LCD Solutions has been designed and manufactured to encompass a range of Flat Panel Displays for Military or Industrial Applications. The prime focus is to facilitate clearread more...

The cView Series has been design and manufactured to produce a range of Flat Panel Displays for Military or Industrial Applications. The prime focus is to facilitate clear viewing and enhance image quality without compromising on the environmental & EMI compliance.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display(LCD) that uses thin-film transistor (TFT) technology to improve image qualities such as addressability and contrast. Application: Television Sets, Computer monitors, Mobile Phone, Handheld Device, POS Device, Tablet Phones, Homeread more...

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey