cholesteric lcd display in stock

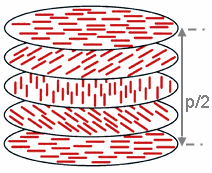

A cholesteric liquid crystal display (ChLCD) is a display containing a liquid crystal with a helical structure and which is therefore chiral. Cholesteric liquid crystals are also known as chiral nematic liquid crystals.

KDI has world class manufacturing expertise in roll to roll manufacturing of liquid crystal films, face shield lenses, and other functional flexible materials in including the award winning flexible Boogie Board eWriter LCD films.

The eWriter works on the principle of anisotropic flow, a unique feature of cholesteric liquid crystals, in which crystals flow at different rates, depending on the direction of pressure being applied.

(PhysOrg.com) -- Currently the screens of e-readers come in two colors, black and white. While the Nook does have a color version out but that screen is an LCD and not an e-ink. While for a while that did create a debate about eyestrain but other companies are looking to catch up to the color.

Fujitsu recently demonstrated a prototype of their next generation cholesteric LCD color digital paper module at the International Digital Publishing Expo. The machine uses a set of Cholesteric liquid crystals to create the display. Cholesteric liquid crystals are different from other methods of creating color LCD displays because this method does not require polarizing plates, reflecting plates, color filters or back lights in order to create the display, which allows them to be thinner than other LCD options.

The trial model, which weighs only weighs 220g, is running a Linux-based operating system, unlike previous versions put out by Fujitsu that used Windows. This new model has an enhanced processing speed, with a write speed of 0.7 seconds and the complete elimination of dithering on the 4,096-color range display that is 8" on the diagonal. The final screen resolution is 157 dpi with a contract ratio of 8:1.

Yuan H (1996) Bistable reflective cholesteric displays. In: Crawford GP, Zumer S (eds) Liquid crystals in complex geometries. Taylor & Francis, London, pp 265–280

A team of researchers headed by Dan Luo within the Department of Electrical and Electronic Engineering at the Southern University of Science and Technology (Shenzhen, China) has developed improved Cholesteric Liquid Crystal (CLC) materials for use in electronic displays.

A recent article by the team is entitled “Full-color reflective display based on narrow bandwidth templated cholesteric liquid crystal film.” It was published in Optical Materials Express 16, Vol. 7, No. 1, 1 Jan 2017. A copy of this article is available on line and can be found here.

A layer of CLC will strongly reflect light that has a wavelength half the pitch of the helical twist. In a reflective display, highly saturated colors are needed to produce a wide color gamut. Achieving a wide color gamut with CLCs requires a narrow reflection band-gap. However, in conventional CLC materials, the reflection band-gap is around 90 nm, which is too wide for practical applications. In their recent work, the researchers address this issue by the use of so-called templated CLC Films (CLCFs).

The researchers fabricated several devices to demonstrate the potential of flexible reflective films that were refilled with small birefringence liquid crystals. In doing this, the electro-optic properties of the cholesteric material were not used but, rather, just the reflective properties of the material as a passive film. Three reflective displays were fabricated. The details of the film fabrication and specifications are presented in the technical article. The figure below is a schematic diagram of the configuration and principle of operation of the reflective display.

National Engineering Lab for TFT-LCD Materials and Technologies, Department of Electronic, Engineering, Shanghai Jiao Tong University, Shanghai 200240, China; nc.ude.utjs@321oayoag (Y.G.); nc.ude.utjs@xyl_utjs (Y.L.)

Cholesteric liquid crystals (CLCs) have been widely applied in optical filters due to Bragg reflection caused by their helical structure. However, the reflectivity of CLC filters is relatively low, commonly less than 50%, as the filters can only reflect light polarized circularly either left- or right-handedly. Therefore, a high-reflective CLC filter with a single-layer template was proposed which may reflect both right- and left-handed polarized light. The CLC filters of the red, green, blue color were fabricated by the templating technology, which show good wavelength consistency. Additionally, a multi-phase liquid crystal filter with high reflectance was demonstrated by the single-layer templating technology. The templated CLC or multi-phase liquid crystal filters show great potential applications in the optical community, reflective display, and lasing.

Optical filters with liquid crystal (LC) materials have attracted significant attention in the optical community and color display [1,2]. Various types of optical filters, such as Bragg grating filters, color filters, and waveguide filters, have been developed [3,4,5,6]. For the LC materials among optical filters, cholesteric liquid crystals (CLCs) have been widely applied due to their self-assembled structures and simple fabrication [7]. The CLCs possess the intrinsic features of pitch- and polarization-selective reflection of the incident light [8,9,10,11,12]. For pitch-selective reflection of CLCs, the reflection central wavelength is determined by p and n, where p is the pitch length which is determined by chiral dopant concentration and helical twist power (HTP), n = (n0 + ne)/2, n0 and ne are the ordinary and extraordinary refractive indices of LC, respectively [13,14,15,16,17]. Different pitch length, leading to the different reflection central wavelength that covers from ultraviolet to infrared, can be achieved by changing the chiral dopant concentration. Because the reflection by the CLCs with a helical structure is selective, only circularly polarized incident light with the same handedness as that of CLC is reflected, while light with the opposite handedness is transmitted. Accordingly, for the unpolarized or linearly polarized incident light, the reflectance of a single CLC film is equal to, at most, 50% [11,18]. However, a higher reflectivity of a CLC device is desired to apply in many fields, including reflective display, lasing and mirrors, especially in optical filters.

To improve the reflectance of CLC devices, several approaches have been proposed. A single layer of CLC materials whose optical characteristic go beyond the 50% reflectance limit was first proposed. The CLC exhibited a thermally induced helicity inversion by introducing photopolymerizable monomers and the reflectance exceeded 50% when measured at the temperature assigned at a cholesteric helix with the same pitch but a left-handed sense before reaction [12,19]. A stack of two individual single-chiral CLC cells which can reflect both right-and left-circularly polarized light was proposed [20,21]. One wash out–refilling process that functions by refilling optical adhesive into a cholesteric film, assembled utilizing two cholesteric templates with opposite handedness, was proposed [22]. In addition, a half-wave plate, converting the single-handedness polarized light to opposite handedness light, could be used to insert between two separated CLCs with the same handedness [23,24]. Although effective in realizing high-reflective CLC devices, the approaches mentioned above suffer from complicated design and fabrication, increased insertion loss and optical defects at the interfaces, and increased weight [10,25]. In this paper, we demonstrate CLC filters with high-reflectivity based on a single-layer helical structure and simple fabrication process. The filters are formed via CLC templating technology with a wash out–refill process which functions by refilling the CLC into a single layer CLC template with opposite handedness [10,26,27]. This templating technology is effective in realizing high-reflectivity single-layer CLC filters for all red, green, and blue colors. Compared with the approaches mentioned above, the preparation process of fabricated CLC filters is simple and applicable to large-scale application. According to our previous study where the effect of multi-phase liquid crystals was investigated [28], the multi-phase liquid crystal filters with high reflectivity are demonstrated in this paper. By refilling a CLC with left-handedness into a blue phase liquid crystal (BPLC) template with right-handedness, a multi-chiral BPLC filter with a single layer was fabricated. Herein, the fabrication of the high-reflectivity CLC or BPLC filters with a single layer show great potential for applications such as flexible reflective displays, optical communication, lasing, and color filters.

In our previous work, a multi-phase or multi-pitch twist structure LC can be fabricated by the wash out–refilling process [28]. Therefore, in this study, we have considered that the multi-chiral CLC filters with high reflectivity can be obtained by the wash out–refilling process. For achieving the purpose, the polymer-stabilized CLC(PS-CLC) precursors with right-handedness, using the different concentration chiral dopant to reflect light of different colors, were used to make the cholesteric templates with single layer and the left-handed CLCs used as refilling materials were prepared. The polymer networks with right-handedness were formed by wash-out process and, after refilling the left-handed CLCs into the templates, the two handedness could co-exist in a device which may reflect both right- and left-circularly polarized light.

The materials prepared for our experiments include the following components: a positive nematic liquid crystal (BPH006, Jiangsu Hecheng Display Technology Co., Ltd. (HCCH), Nanjing, Jiangsu, China), a chiral dopant with right-handedness (R5011, Nanjing Murun, Nanjing, Jiangsu, China), a chiral dopant with left-handedness (S811, HCCH), an ultraviolet (UV) curable monomer (TMPTA, Shanghai Macklin, Shanghai, China), a cross-linker agent (C3M, HCCH), and a photo-initiator (IRG184, HCCH). The chemical structures of these materials are shown in Figure 1. The mixtures of PS-CLC precursors with right-handedness were composed of BPH006, R5011, TMPTA, C3M, and IRG184, and the CLC mixtures with left-handedness were composed of BPH006 and S811. Because the value of HTP of S811 is very small compared to R5011, the concentration of S811 needs to be high enough to obtain the left-handed CLC whose reflective peak is the same as the templated-CLC (T-CLC) with right-handedness. Table 1 lists PS-CLC materials with different right-handed chiral dopant concentration and CLC materials with different left-handed chiral dopant concentration composition corresponding to red, green, and blue colors.

The spectral characteristics of CLC filters can be analyzed by equipping the measurement system which is shown in Figure 6. All the Bragg reflection spectra were measured by unpolarized light provided by a tungsten bromide lamp with the whole visible light range. The unpolarized light passing through a monochromator (Omni-λ1509, Zolix, Beijing, China) was incident on the sample, and the intensity signals of incident light passing through the sample were collected by a data acquisition system (DCS300PA, Zolix, Beijing, China) utilizing an optical fiber. Since the devices were fixed on the position shown in Figure 6, we characterized the properties of templated cholesteric liquid crystal filters with transmittance spectra. The transmittance was calculated as the ratio of the measured light intensity in the measurement system with a sample cell to that with an empty cell. Although the transmittance of the transmittance spectra may be decreased by scattering or absorbing, the central wavelength and the maximum transmissivity/reflectivity of the transmittance and reflection spectra had almost the same values.

The normalized transmission spectrum of polymer-stabilized cholesteric liquid crystals (PS-CLCs) and templated cholesteric liquid crystals (T-CLCs) for red, green, and blue colors.

In conclusion, a novel high-reflectivity CLC filter with a single layer template was proposed, which may reflect both right- and left-circularly polarized light. The templated CLC filters with a single layer of red, green, and blue color were fabricated in the wash out–refilling process, and the improvement of reflectivity was confirmed to be connect to the wavelength consistence. Moreover, a high-reflectivity multi-phase BPLC filter with a single layer template was achieved, which means that the technology for enhancing reflectivity applies equally to multi-phase LC filters with a single layer. The single layer templated CLC or BPLC filters show a simple process and great potential applications in the optical community, display, and lasing.

2. Huang Y., Zhang S. Optical filter with tunable wavelength and bandwidth based on cholesteric liquid crystals. Opt. Lett.2011;36:4563–4565. doi: 10.1364/OL.36.004563. [PubMed] [CrossRef]

3. Gevorgyan A.H. Resonant interaction of light with a stack of alternating layers of a cholesteric liquid crystal and an isotropic medium. Phys. Rev. E.2015;92:062501. doi: 10.1103/PhysRevE.92.062501. [PubMed] [CrossRef]

5. Huang Y., Zhang S. Widely tunable optical filter with variable bandwidth based on the thermal effect on cholesteric liquid crystals. Appl. Opt.2012;51:5780–5784. doi: 10.1364/AO.51.005780. [PubMed] [CrossRef]

8. Kim J., Kim H., Kim S., Choi S., Jang W., Kim J., Lee J.H. Broadening the reflection bandwidth of polymer-stabilized cholesteric liquid crystal via a reactive surface coating layer. Appl. Opt.2017;56:5731–5735. doi: 10.1364/AO.56.005731. [PubMed] [CrossRef]

9. Ogiwara A., Kakiuchida H. Thermally tunable light filter composed of cholesteric liquid crystals with different temperature dependence. Sol. Energy Mater. Sol. Cells.2016;157:250–258. doi: 10.1016/j.solmat.2016.05.039. [CrossRef]

11. Mitov M. Cholesteric liquid crystals with a broad light reflection band. Adv. Mater.2012;24:6260–6276. doi: 10.1002/adma.201202913. [PubMed] [CrossRef]

12. Mitov M., Dessaud N. Going beyond the reflectance limit of cholesteric liquid crystals. Nat. Mater.2006;5:361–364. doi: 10.1038/nmat1619. [PubMed] [CrossRef]

13. Ranjkesh A., Yoon T.H. Thermal and electrical wavelength tuning of Bragg reflection with ultraviolet light absorbers in polymer-stabilized cholesteric liquid crystals. J. Mater. Chem. C.2018;6:12377–12385. doi: 10.1039/C8TC04563A. [CrossRef]

14. Li Y., Liu Y., Luo D. Optical thermal sensor based on cholesteric film refilled with mixture of toluene and ethanol. Opt. Express.2017;25:26349–26355. doi: 10.1364/OE.25.026349. [PubMed] [CrossRef]

15. Wu P.C., Wu G.W., Timofeev I.V., Zyryanov V.Y., Lee W. Electro-thermally tunable reflective colors in a self-organized cholesteric helical superstructure. Photon. Res.2018;6:1094–1100. doi: 10.1364/PRJ.6.001094. [CrossRef]

16. Mcconney M.E., Tondiglia V.P., Hurtubise J.M., White T.J., Bunning T.J. Photoinduced hyperreflective cholesteric liquid crystals enabled via surface initiated photopolymerization. Chem. Commun.2011;47:505–507. doi: 10.1039/C0CC02215B. [PubMed] [CrossRef]

19. Mitov M., Dessaud N. Cholesteric liquid crystalline materials reflecting more than 50% of unpolarized incident light intensity. Liq. Cryst.2007;34:183–193. doi: 10.1080/02678290601116175. [CrossRef]

20. Makow D.M. Peak reflectance and color gamut of superimposed left- and right-handed cholesteric liquid crystals. Appl. Opt.1980;19:1274–1277. doi: 10.1364/AO.19.001274. [PubMed] [CrossRef]

21. Mccony M.E., Tondiglia V.P., Hurtubise J.M., Natarajan L.V., White T.J., Bunning T.J. Thermally induced, multicolored hyper-reflective cholesteric liquid. Adv. Mater.2011;23:1453–1457. doi: 10.1002/adma.201003552. [PubMed] [CrossRef]

22. Li Y., Liu Y.J., Dai H.T., Zhang X.H., Luo D., Sun X.W. Flexible cholesteric films with super-reflectivity and high stability based on a multi-layer helical structure. J. Mater. Chem. C.2017;5:10828–10833. doi: 10.1039/C7TC03915H. [CrossRef]

25. Ranjkesh A., Choi Y., Huh J.W., Oh S.W., Yoon T.H. Flexible, broadband, super-reflective infrared reflector based on cholesteric liquid crystal polymer. Sol. Energy Mater. Sol. Cells.2021;230:111137. doi: 10.1016/j.solmat.2021.111137. [CrossRef]

26. Guo J., Wu H., Chen E., Zhang L., He W., Yang H., Wei J. Fabrication of multi-pitched photonic structure in cholesteric liquid crystals based on a polymer template with helical structure. J. Mater. Chem.2010;20:4094–4102. doi: 10.1039/b926670d. [CrossRef]

27. Guo J., Yang H., Li R., Ji N., Dong X., Wu H., Wei J. Effect of Network Concentration on the Performance of Polymer-Stabilized Cholesteric Liquid Crystals with a Double-Handed Circularly Polarized Light Reflection Band. J. Phys. Chem.2009;113:16538–16543. doi: 10.1021/jp903394r. [CrossRef]

Metasurfaces can enable polarization multiplexing of light so as to carry more information. Specific polarized light necessitates bulk polarizers and waveplates, which significantly increases the form size of metasurface devices. We propose an electrically programmable metasurface enabled by dual-frequency cholesteric liquid crystals (DF-CLCs) for simultaneous near- and far-field displays. Moreover, the integrated device can be electrically programmed to demonstrate 6 different optical images by engineering the DF-CLCs with frequency-modulated voltage pulses. Such programmable metasurfaces are potentially useful for many applications including information storage, displays, anti-counterfeiting, and so on.

Electrowetting display (EWD), which is based on the quick manipulation of microfluid, is a type of reflective electronic paper display technology [1]. Compared with the commercialized electronic paper product of electrophoresis display (EPD), EWD has the same advantages, including low energy consumption, visual healthy and flexibility. Moreover, EWD is capable of realizing “color” and “video” display simultaneously, which is rather difficult to achieve by other reflective display technologies [2]. Therefore, EWD has become one of the mainstreams of electronic paper display in recent decade.

The concept of EWD was pioneered by G. Beni et al. [3, 4] in 1981, who used the electrowetting effect to manipulate the liquid movement in the pixel structure, so as to change the optical spatial coherence in the pixel, and realize display by switching between white and colored state. Fundamentally, electrowetting is based on electrocapillarity, which was first discovered by Gabriel Lippmann in 1875 and raised the famous Young-Lippmann equation [5]. In 1993, Berge proposed the concept of electrowetting based on dielectric layer [6], which became the basis of modern electrowetting devices [7], such as displays, lenses [8], microfluidic platform [9], heat transfer [10], energy conversion [11] etc. In 2003, Robert A. Hayes reported a video-speed electronic paper based on electrowetting [1], and started the research of EWD technology officially.

So far, the performance of EWD devices have been greatly improved in the past 2 decades, including the reflectivity [12], response time [13] and reliability [14, 15]. EWD prototypes with high brightness and video-speed has also been demonstrated. However, the EWD color display is still unsatisfactory, due to the difficulties in achieving high brightness and high color gamut simultaneously [16]. For reflective color display, the additive color mixing with red (R), green (G) and blue (B) color filter is unfavorable, since each of the color subpixels absorbs roughly 2/3 of the incident white light and thus reduce the brightness/gamut performance [17]. By contrast, subtractive color, mixing with vertical cyan (C), magenta (M) and yellow (Y) stack, is more promising for reflective EWD with wide color gamut while maintaining high reflectivity [18–20]. As reported by H. You et al. [18], the CMY color EWD layers can be switched and are responsible for RGB light control independently in the vertical direction. By controlling the opening rate of each layer, the three primary colors of different gray scales can be obtained, and finally achieve full color display.

Currently, although the multi-layered EWD configuration can achieve high brightness in principle, however, it also causes evident light loss due to the excessive number of functional layers and limit the brightness of the device ultimately. To reduce the light loss, this study report a new approach to enhance the optical performance of the EWD device. Selective reflection films made of polymer cholesteric liquid crystal (PCLC) were added under each layer to reflect the light that has been modulated. The reflectance and color gamut of this new EWD device structure were studied by experiment and simulation, and both results show that this method greatly enhanced the reflectivity and color gamut of tri-layers EWD.

In tri-layered EWD device, CMY oils are used to absorb RGB light respectively. As shown in Figure 1B, when the visible light passes through the layer consisting of Y oil, the blue light is absorbed, whereas the red and green light pass through the Y oil layer. Subsequently, the transmitted light continues to pass through the M oil layer, and the green light is absorbed. In this process, only the red light can pass, and is absorbed by Coil finally. Therefore, when the three layers of ink are spread, the pixels show black. By contrast, when the three layers of ink are contracted, the visible light can pass through the open area, thus resulting in white pixels. It can be inferred that the modulation of the three ink layers on the RGB tri-color light is independent. Moreover, by controlling the open rate of each layer of ink, the absorption of RGB light can be adjusted, and the full-color display can finally be realized.

However, it should be emphasized that the aforementioned mechanism to realize color display suffers from strong losses in the process of light passing through the entire device and reflecting back in a three-layer superimposed EWD device, although in principle other ink layers have no effect on the light outside the absorption spectrum. Taking the blue light as an example, the blue light in the reflected spectrum is regulated by the uppermost yellow ink layer, which has already been completed by the first layer of EWD devices. However, the regulated blue light still needs to pass through the lower two layers of the device to reach the reflective film and again go through the three layers of the device before it comes to human eyes. In this process, the intensity of the blue light is weakened by the absorption of the material, the reflection of the interface and the diffraction of the structure, which eventually leads to a significant reduction in the reflectivity of the blue light.

In order to realize the selective reflection of the visible spectrum, PCLC films were employed as the dichromatic reflector in this work. Cholesteric liquid crystal (CLC) is a kind of one-dimensional photonic material with a chiral-spiral structure with Bragg reflective properties, which reflect circularly polarized light in the same direction as its chiral spiral (plus references). According to the Bragg reflection, the reflected band λo of CLC is directly related to its pitch P and refractive index, which can be described by following formula:

An optical model of tri-layer EWD device is built in software to simulate the effect of adding PCLC films on the reflectivity and color gamut of the device. The side view and equiaxial view of the optical model are shown in Figure 3A. To save computing resource, the model is composed of an array of 50 × 50 pixels. The geometric and optical parameters of each functional layer are set according to the sample in the experiment, where the thickness and refractive index of each layer are shown in Figure 3C. The absorption spectrum of CMY oil and the reflection spectrum of PCLC films are set according to the results in Figures 2B,D. In the simulation model, the reflector used in the model is the standard Lambert diffuse reflective surface, and the light source is the D65 standard white parallel light source, which shines on the device at an angle of 45°. A monitor is set vertically above the device as a sensor to record the light intensity and color coordinates of the reflected light. By establishing the switching states of different membrane layers, the reflected light intensity and the reflected light color coordinates of the device when displaying six primary colors (namely RGB, CMY, black and white) are simulated and calculated.

In order to optically characterize the performance of EWD devices, a system (Figure 3B) was built in the dark room, according to the electronic paper display measurement standard IEC-62679. In the test system, a collimated D65 light source with divergence angle less than 5° and illuminance higher than 65,000 Lux was used to illuminate on the center of the display screen under test. The angle between the lighting direction and the measured EWD device surface is 45°. To measure the brightness and chromaticity coordinates of the six primary colors on EWD device, a colorimeter (Topcon, SR-UL1R) was putted perpendicular to the surface of the EWD device with a measuring distance of 50 cm.

Generally, the color gamut refers to the range of colors that the display device can show. For subtractive color mixing implemented by CMY, the color that can be achieved is the area enclosed by a hexagonal shape on the chromaticity map connected by the color coordinates of the CMYRGB six primary colors. The NTSC color gamut coverage of the display GEWD is usually defined as the ratio between the hexagonal area SEWD and the NTSC standard triangle area SNTSC . It can be calculated by following formula:

The value of the SNTSC is 0.1582, and the color display gamut of the device can be calculated by testing the chromaticity coordinates of the display in the C, M, Y, R, G, B primary colors in the CIE1931 chromaticity space.

As EWD is a type of reflective display technology, the reflectivity which determines the display brightness is an important parameter. It can be seen from both the simulation and experimental results that the reflectivity of the device has been significantly improved by adding the PCLC films. Specifically, the most significant improvement is the reflectivity of the cyan. For cyan display, it is necessary to open the ink of the upper Y and M layers and close the ink of the lower C layer. In such conditions, the red light is absorbed while the blue light and green light are reflected. This is realized by using the two reflective layers of RF-B and RF-G, which help to reflect the blue light and green light subsequently before they go through the tri-layer device. Therefore, the loss of the blue light and green light is greatly minimized, thus significantly improving the reflectivity of cyan. Similarly, the reflectivity of the blue and green has also been significantly improved. Regarding to the blue, it is necessary to absorb the green and red light, while reflect the blue light. This is accomplished by using the RF-B reflective layer to reflect the blue light after it passing through the uppermost device, thus saving the blue light to the greatest extent. For green, it is necessary to absorb the blue and red light, while reflect the green light. It can be seen from Figure 2B that the bottom cyan ink has a certain absorption of green light. Hence, when the RF-G reflective layer does not need to pass through the lowest layer of the device, the green light reflectance is improved more than the blue light. Meanwhile, the results show that the least increase in reflectivity is the red, due to the fact that the cyan ink that regulates the red light is located in the lowest layer, and the red light must pass through the three-layer device anyway, so the presence or absence of RF has little effect on the reflectivity of the red light. Overall, after the addition of PCLC films, the overall reflectivity of the device has been increased by more than 30%, mainly from the increasement of the reflectivity of the blue light and green light. Therefore, by adding a selective reflective layer between the display layers, it is indeed possible to greatly improve the reflectivity of the device by reducing the invalid light loss when light passes through the three layers of the device.

It can be inferred from the above results that the addition of PCLC films with selective reflection characteristics greatly improves the reflectivity of the blue light and green light, via directly reflecting the blue light and green light without passing through the three layers of EWD devices. Both the reflectivity and the color gamut of the tri-layer EWD device have been significantly improved, which can help to mitigate the problems in the current color EWD display device.

We proposed a novel full-color reflective electrowetting display device, consisting of three independent PCLC reflection films that can reflect the red, green and blue circularly polarized light respectively. PCLC films embedded in the device can effectively reduce the reflectance and gamut value. The results of simulation and experiment are in good agreement. It is demonstrated that with the PCLC films, the reflectivity is improved by 20%, while the color gamut is improved by 80%, which is sufficient for the daily display demand of E-paper. The proposed EWD device containing PCLC reflection films provide a new strategy to improve the brightness and color gamut of current EWD device, and is promising for realizing the full-color E-paper display. It is of great significance for the promotion and application of full-color video electro-wetting electronic paper display devices.

This research was funded by National Key R&D Program of China (2021YFB3600602), Science and Technology Program of Guangzhou (Nos. 202201,010351, 2019,050001), Natural Science Foundation of Guangdong Province (Nos. 2020A1515010715, 2021A1515010623), Program for Chang Jiang Scholars and Innovative Research Teams in Universities (No. IRT_17R40), Program for Guangdong Innovative and Enterpreneurial Teams (No. 2019BT02C241). This work also supported by the Guangdong Provincial Key Laboratory of Optical Information Materials and Technology (No. 2017B030301007), Guangzhou Key Laboratory of Electronic Paper Displays Materials and Devices (201705030007) and the 111 Project.

2. Feenstra B, Hayes R, Van Dijk R, Boom R, Wagemans M, Giraldo A, et al. (2006).Electrowetting-based displays: bringing microfluidics alive on-screen. in: IEEE International Conference on Micro Electro Mechanical Systems: 22-26 Jan. 2006: Turkey

12. Wu H, Hayes RA, Li F, Henzen A, Shui L, Zhou G. Influence of fluoropolymer surface wettability on electrowetting display performance. Displays (2018) 53:47–53. doi:10.1016/j.displa.2018.02.002

13. Dou Y, Tang B, Groenewold J, Li F, Yue Q, Zhou R, et al. Oil motion control by an extra pinning structure in electro-fluidic display. Sensors (2018) 18(4):1114. doi:10.3390/s18041114

14. Zhou R, Ye Q, Li H, Jiang H, Tang B, Zhou G. Experimental study on the reliability of water/fluoropolymer/ITO contact in electrowetting displays. Results Phys (2019) 12:1991–8. doi:10.1016/j.rinp.2019.02.037

15. Dou Y, Chen L, Li H, Tang B, Henzen A, Zhou G. Photolithography fabricated spacer arrays offering mechanical strengthening and oil motion control in electrowetting displays. Sensors (2020) 20(2):494. doi:10.3390/s20020494

16. Kuo SW, Chang YP, Cheng WY, Lo KL, Lee DW, Lee HH, et al. 34.3: Novel development of multi-color electrowetting display. SID symposium. Dig Tech Pap (2010) 40(1):483–6.

17. Giraldo A, Aubert J, Bergeron N, Li F, Mvd W, Massard R, et al. 34.2: Transmissive electrowetting-based displays for portable MultiMedia devices. J Soc Inf Disp (2010) 18(4):317–25. doi:10.1889/jsid18.4.317

19. Wei-Yuan L, Cheng W, Yung-Hsiang C, Liang C-C. A stacking color electrowetting display for the smart window application. SID Int Symp Dig Tech Pap (2011) 42(1):78–81. doi:10.1889/1.3621448

20. Yang G, Tang B, Yuan D, Henzen A, Zhou G. Scalable fabrication and testing processes for three-layer multi-color segmented electrowetting display. Micromachines (2019) 10(5):341. doi:10.3390/mi10050341

Japan Display Flexible Electronic Paper - Apr 2010A Flexibile Cholesteric Liquid Crystal Display (ch-lcd) Rolled Book Developed by Taiwan"s Industrial Technology Research Institute is Seen at 20th Fintech Japan Display 2010 Exhibition in Tokyo Japan 15 April 2010 Japan Tokyo

Cholesteric liquid crystal (ChLC) bi-stable displays were fabricated on 100 μm thick flexible glass front- and backplane substrates. The flexible glass substrates were 250 mm × 300 mm in size, and the displays were fabricated using Gen2 equipment by temporarily attaching the substrates to processing carriers. No significant fabrication issues were encountered that would limit process optimization of these devices. Benefits of the flexible glass substrates observed compared to previously…Expand

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey