tft lcd frame buffer supplier

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

This application note describes the i.MX6 CPU graphical system and the steps to define a new custom TFT (Thin Film Transistor) display panel in Digi Embedded Yocto and discusses the most standard panels available. Some panels may need special consideration.

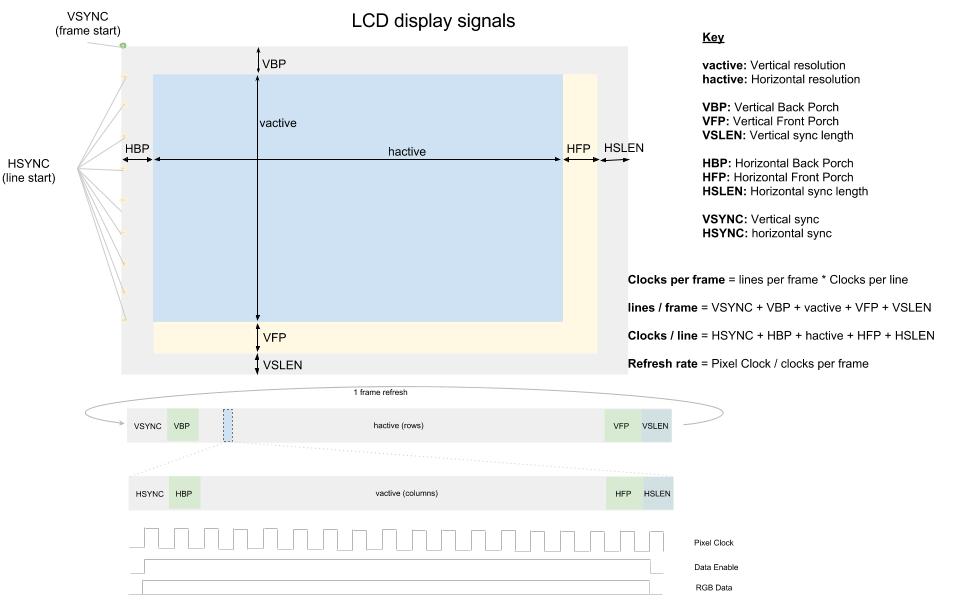

An LCD panel is a matrix of pixels that are divided into rows and columns. These pixels are individually painted according to different signals and timing parameters, and you can control each pixel"s color individually. The panel is continuously refreshed, typically at around 60 Hz, from the contents of the frame buffer memory. Each memory location on the frame buffer corresponds to a pixel on the LCD panel.

A 1024 x 600 resolution display requires 614400 memory locations, with each location having a number of possible colors. The number of bits needed to describe the available colors is called bits per pixel (bpp). For example, 16 bpp can describe 65536 colors and 24 bits can describe 16777216 colors (known as true color). A panel with 614400 24-bit locations requires a 1800 KB frame buffer.

VSYNC: Vertical synch (FPFRAME, FLM, SPS or TV) indicates the end of the current frame. The next line index should restart at zero in the upper-left corner.

Every manufacturer provides display timings in a slightly different way and some provide more detail than others. Most LCD panels work with a range of timing parameters.

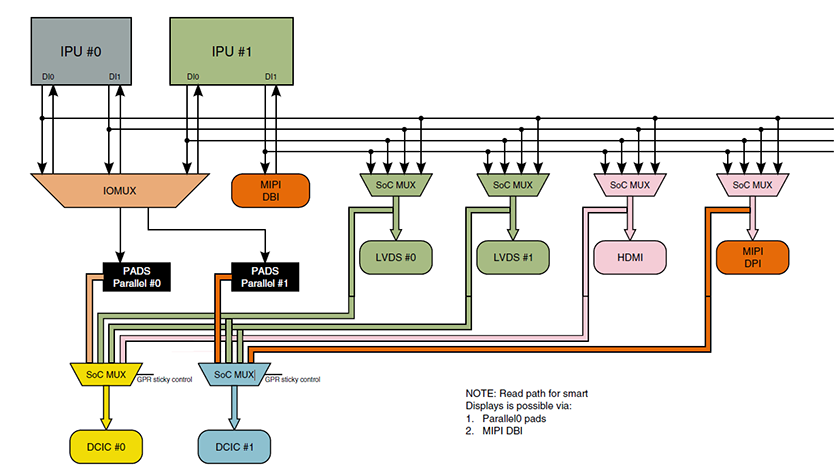

The i.MX6 IPUs define a series of frame buffer devices (/dev/fbN, where N is an index number starting at zero) that correspond to the graphical capabilities of the SoC.

The i.MX6 Dual/Quad has two IPUs, each containing two DIs. Additionally, the driver allows for an overlay frame buffer per IPU (to be displayed over the frame buffer of DI0). These overlay frame buffers are also represented by nodes /dev/fbN.

Frame buffer devices provide an abstraction for the graphics hardware. You must create a frame buffer entry on your platform"s device tree file and bind it to a graphics driver through the compatible property.

The following example creates a frame buffer and binds it to the MXC frame buffer device driver (drivers/video/mxc/mxc_ipuv3_fb.c).Frame buffer node binding to MXC graphics drivermxcfb1: fb@0 {

The driver"s binding documentation at Documentation/devicetree/bindings/fb/fsl_ipuv3_fb.txt describes additional properties for the frame buffer. You must complete the node with required and optional properties that match your hardware, for example:

You can create as many frame buffer entries as you have available display interfaces in your platform. For example, the i.MX6 Dual/Quad has two IPUs, each containing two display interfaces, equaling a total of four displays:

LCD displays must be created as nodes in the device tree with a display-timings subnode. Display timings binding documentation at Documentation/devicetree/bindings/video/display-timing.txt explains the required timing properties to describe an LCD.lcdname {

hfront-porch is the horizontal front porch, the number of clock pulses (pixels) between the last valid pixel data in the line and the next HSYNC pulse. According to the LCD data format, this value is zero.

vfront-porch is the vertical front porch, the number of lines (HSYNC pulses) between the last valid line of the frame and the next VSYNC pulse. According to the LCD data format, this value is zero.

NoteThe recommended timings from the LCD datasheet often do not work perfectly, as each platform introduces noise and delays that affect the display"s signals and timings.

vfront-porch is the vertical front porch, the number of lines (HSYNC pulses) between the last valid line of the frame and the next VSYNC pulse. The datasheet does not provide this number but it provides the complete Vertical period (TV) and the Vertical period (High) (TVd) so you can calculate the vertical front porch as TV - TVd = 831 - 800 = 311.

To run the application, call fbtest from a console. The application shows the test color chart by default to frame buffer 0 (/dev/fb0). To show the test color chart on a different frame buffer, export the variable FRAMEBUFFER:export FRAMEBUFFER=/dev/fb2

This color chart displays a white one-pixel frame at the edges of the LCD (which allows you to verify correct position and width/height), and gradients of red, green, blue, and white (which allow you to verify correct color depth and format).

TFT LCDs have become the norm for small-to-medium size displays in a variety of products within industrial, medical, POS and consumer applications. Compared to passive-addressed monochrome LCDs, TFT displays offer higher contrast, wider viewing angles, faster response time and full color. And, TFT LCDs are now on cost parity with similar size passive LCD displays.

A typical TFT LCD module product consists of a TFT LCD panel, one or more COG (chip-on-glass) driver ICs, a backlight unit, and an interface FPC. Several TFT display interface technologies coexist today. Picking the right technology depends on specific end-product concerns. Most often the display panel input will dictate that choice since TFT panels are designed to be COG bonding pad compatible with a very limited number of driver ICs. This article discusses the interfaces between TFT LCD modules and the typical CPUs found in embedded applications.

Typical TFT interfaces are determined by the particular TFT panel size and resolution, as shown in the below table. HDMI and eDP require interface converting boards and generally are not used for small to medium-size TFT LCDs.TFT LCD SizesResolutionsTypical Interfaces UsedUp to 3.5″128×160 to 240×320SPI, parallel MPU or RGB

Only the three SPI signals, a CS, and a reset signal are needed. Drawbacks are the inability to read from the display, only write. Also, the frame rate is low and unsuitable for displaying video or high-resolution images.

The LCD controller signals are two types: data signals and control signals. The data signals are connected to the LCD data bus and depend on the LCD color depth (8-bit, 9-bit, 16-bit, 18-bit). The control signals are used to define the operation type (read or write), and whether the operation involves in addressing LCD registers or the display RAM.

An RGB interface is a special kind of parallel interface. This interface works for displays without a frame buffer. The MCU is responsible for updating the display, by providing both the RGB sub-pixel data (16-bit, 18-bit, 24-bit) and the timing signals (HSYNC, VSYNC, DE, CLK).

LVDS interfacing has several benefits for TFT displays. It is much less susceptible to EMI and crosstalk issues, allowing the transmitting device to be located farther from the display. Also, LVDS generally consumes less power, pin counts are lower and there are far fewer worries about signal integrity.

Modern TFT driver ICs are highly integrated chips combining the source driver, gate driver and timing controller (TCON) – as well as other functional circuits such as memory, power circuit, and image processors – into one single IC die. Some driver ICs support multiple interfaces that are selectable on the module FPC or through initialization code firmware.

As a designer and manufacturer of custom LCD modules, New Vision Display works with customers to select the most appropriate and cost-effective TFT display and electronic interface solution for their particular requirement. New Vision Display has nearly 30 years of industry experience as one of the world’s leading TFT LCD screen manufacturers.

MCU interfaces are available in two standard forms, Intel-8080 and Motorola-6800 series. These interfaces communicate through an integrated display controller and frame buffer.

We know that you might have some bubbling questions by now, such as, what is an Integrated display controller? What is a frame buffer? What do all of them get to do with the MCU interface? What is the difference between RGB and MCU interfaces?

The frame buffer is the memory space that holds the pixel data being displayed. There are internal frame buffers in smart displays that are stored on RAM. The MCU display interface reads the frame buffer every time to update the display.

The MCU interface progresses through frames at an increased rate to read pixels from the display controller. It can read and write data and display images directly from the internal memory.

Microtips Technology, a US-based LCD display manufacturer and distributor with global exposure, has been using both RGB and MCU interfaces in their TFT display panels and touch panel displays. However, most of their deliverables feature MCU interfaces primarily.

MCU interfaces are available in two standard forms, Intel-8080 and Motorola-6800 series. These interfaces communicate through an integrated display controller and frame buffer.

We know that you might have some bubbling questions by now, such as, what is an Integrated display controller? What is a frame buffer? What do all of them get to do with the MCU interface? What is the difference between RGB and MCU interfaces?

The frame buffer is the memory space that holds the pixel data being displayed. There are internal frame buffers in smart displays that are stored on RAM. The MCU display interface reads the frame buffer every time to update the display.

The MCU interface progresses through frames at an increased rate to read pixels from the display controller. It can read and write data and display images directly from the internal memory.

Microtips Technology, a US-based LCD display manufacturer and distributor with global exposure, has been using both RGB and MCU interfaces in their TFT display panels and touch panel displays. However, most of their deliverables feature MCU interfaces primarily.

It"s new update. In function st7789v_spi_write at panel-sitronix-st7789v.c file. I changed code xfer.bits_per_word = 8 instead of 9 (see in below). The board can send bytes over SPI success after. But LCD still not work

To be honest, I don"t know what exactly problem in here? I"ve already check by oscilloscope, data was sent over SPI when booting and RGB normal but why LCD not work? Do you have any ideal for checking this one?

Hi guys, welcome to today’s tutorial. Today, we will look on how to use the 1.8″ ST7735 colored TFT display with Arduino. The past few tutorials have been focused on how to use the Nokia 5110 LCD display extensively but there will be a time when we will need to use a colored display or something bigger with additional features, that’s where the 1.8″ ST7735 TFT display comes in.

The ST7735 TFT display is a 1.8″ display with a resolution of 128×160 pixels and can display a wide range of colors ( full 18-bit color, 262,144 shades!). The display uses the SPI protocol for communication and has its own pixel-addressable frame buffer which means it can be used with all kinds of microcontroller and you only need 4 i/o pins. To complement the display, it also comes with an SD card slot on which colored bitmaps can be loaded and easily displayed on the screen.

Due to variation in display pin out from different manufacturers and for clarity, the pin connection between the Arduino and the TFT display is mapped out below:

We will use two libraries from Adafruit to help us easily communicate with the LCD. The libraries include the Adafruit GFX library which can be downloaded here and the Adafruit ST7735 Library which can be downloaded here.

We will use two example sketches to demonstrate the use of the ST7735 TFT display. The first example is the lightweight TFT Display text example sketch from the Adafruit TFT examples. It can be accessed by going to examples -> TFT -> Arduino -> TFTDisplaytext. This example displays the analog value of pin A0 on the display. It is one of the easiest examples that can be used to demonstrate the ability of this display.

The first thing, as usual, is to include the libraries to be used after which we declare the pins on the Arduino to which our LCD pins are connected to. We also make a slight change to the code setting reset pin as pin 8 and DC pin as pin 9 to match our schematics.

Next, we create an object of the library with the pins to which the LCD is connected on the Arduino as parameters. There are two options for this, feel free to choose the most preferred.

In chapter 7, we made use of the segmented LCD display on the Wonder Gecko Starter Kit through the use of a pre-built LCD library and driver when designing the user interface for the sprinkler timer. That made things easy for us, and we didn’t really need to dwell on how the driver worked. In this chapter, we will dig into some of those details so that we can connect the EFM32 to any kind of display we choose.

The display we will be using for this chapter is the Adafruit 2.8” 240x320 TFT LCD Capacitive Touch screen, shown below. We will interface with it over SPI for transferring image data and I2C for reading the touch interface. We will learn how to interface with it with our own drivers and build our own simple graphics libraries, as well.

Segmented Display: We have already worked with the segmented LCD display in chapter 7, also known as a character display. In such a display, there are a fixed matrix of LCD segments that are preconfigured in hardware to convey specific information. They are not flexible enough to display an image, but they don’t require many pins on the MCU and are easier to program. For example, the number “9” can be formed on such a display with as few as 6 signals.

Note that a new “Memory LCD” described in Silicon Labs application note AN0048 couples a memory device within each pixel so that constant refreshing is not necessary, reducing power consumption as well.

Graphical display screens have many different technologies, from passive-matrix Liquid Crystal Display (LCD) or active-matrix Thin Film Transistor (TFT) LCD, Light Emitting Diode (LED), or Organic LED (OLED). Display technology is not the focus of this chapter. No matter which technology you choose, you will still need to understand the topics of this chapter in order to display your images.

The LCD pixel matrix is the heart of the display. This part is responsible for displaying the image and, in the case of LCD displays, it will either allow or prevent light from a backlight to pass through. In the case of LED displays, the pixel matrix produces the light and forms the image in one step. No matter the process, the pixel matrix is comprised of an array of pixels in height and width of a certain color depth that make up the display. For the display used in this chapter, the color depth is 18 bits, consisting of 6 bits each for the red/blue/green components of a pixel. That means that the information required to paint the screen one time is 240 bits wide x 320 bits tall x 18 bits of color = 172,800 bytes. That’s a lot of data, and it is more data than we can hold in the RAM of the Wonder Gecko MCU. Therefore, it will require some intelligent code to drive the display or an external memory buffer to store the image data.

The backlight is necessary for TFT LCD displays to allow the display to be seen. Without a backlight, a color TFT LCD will show no image. A monochrome LCD is a little different, since the segments can be seen if they are in the “on” state. The brightness of an LCD screen is sometimes controlled by applying a Pulse Width Modulated (PWM) signal to a pin (or pins) that controls the LED backlight. This is exactly what we have already done in the last chapter to dim an LED.

A frame buffer is a block of RAM that holds all of the color information for every pixel (172 kB for this display) that is used to paint a single image (or “frame”) to the display. This buffer is required to exist somewhere in the system because it is used by the display driver chip to refresh the LCD image many times per second.

In a general sense, all display architectures require the above control blocks. The display contains a number of scan lines (depending on the resolution) and an image driver that must continually feed the scan control circuitry with pixel data, even for a static image. The pixel control allows light to pass for an instant, and then the pixel goes dark again. If the scan control circuitry were stopped, the display would turn dark, as all pixels would be turned off. Therefore, the image driver needs a frame buffer of memory somewhere in the system to fetch the pixel data that is needed for every scan. The application fills the frame buffer as new drawing operations change what is to be displayed on the screen.

In the RGB interface mode, the MCU acts as the image driver. This means that it must constantly drive data to the display, refreshing all 320 x 240 pixels many times per second. You can imagine the amount of work that would require of your MCU. If the frame buffer is too big to fit in the MCU RAM, an external memory chip must be used. The frame buffer can be attached to the MCU via serial interfaces such as I2C or SPI for static images such as device menus, but must utilize a parallel interface in order to keep up with the demands of full motion video. The External Bus Interface (EBI) can be used with external memory for maximum speed and ease of use, as long as your particular model of EFM32 supports it. EBI extends the RAM of your EFM32 and allows you to address external memory as if it resides within the RAM address space of the EFM32 itself.

When a display has an integrated device driver chip and frame buffer (such as the Ilitek ILI9341 used in this chapter), the MCU doesn’t have to perform all of the constant refreshing of the display; it only sends data to the driver chip when the image changes. This enables the MCU to offload all of that work to stay focused on the application at hand rather than driving the display.

At the bottom of the software stack, the device driver is the necessary code that customizes your graphics library for your particular display device architecture and physical hardware connection. (Note that a software device driver is not the same thing as the device driver chip on the physical display.) Graphics libraries are flexible, and can be adapted to many different display architectures, but they need to be configured for your display architecture and MCU. The device driver provides this customization, providing the display’s resolution and color depth, mapping the data bus for the display to GPIO pins on your MCU and setting up the memory for the frame buffer (if applicable).

Digital Blocks TFT LCD Controller reference design enables you to accelerate the design-in of TFT LCD panel displays in your system. The reference design centers on the Digital Blocks DB9000AVLN TFT LCD Controller intellectual property (IP) core, which is available in netlist or VHDL/Verilog HDL register transfer level (RTL) formats.

The DB9000AVLN core contains an Avalon® Memory-Mapped system interconnect for interfacing to the Nios® II embedded processor and SDRAM or SRAM controllers (either memory can serve as the frame buffer). Software supplied with this reference design runs on the Nios II embedded processor to place an image in the frame buffer memory and invokes the DB9000AVLN core to drive the LCD panel.

Using the Intel® Quartus® Design Software, you can instantiate the TFT LCD Controller reference design in a Cyclone®, Cyclone® II, or Cyclone® III FPGA development kit. See the Demonstrated Intel® Technology section for a complete list of supported Intel® FPGA development kits.

You can connect your LCD panel to the Intel FPGA development kit with the fabrication of an appropriate cable. Please contact Digital Blocks for more details.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey