lcd panel faults supplier

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

4. #Press the LCD glass side of the panel, if the vertical lines disappear or reappear, it can be judged that the cause of poor contact, OM checking should be able to find the poor contact.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

Founded in 2014, VISLCD is a professional LCD supplier. We provide LCD modules, touch LCD and customized LCD in various sizes with stable quality and competitive price. Welcome to contact us for any LCD demand, thank you.

Liquid crystal displays (LCDs) are the most widely used display technology. Their applications cover TV, mobile phone, appliances, automotive, smart home, industrial meters, consumer electronics, POS, marine, aerospace, military etc. LCD screen display problem can occur for several reasons.

Effect of environmental conditions on the LCD assembly. Environmental conditions include both the effects of temperature and humidity, and cyclic loading.

Effect of manufacturing process. With the development of LCD for more than 40 years and the modern manufacturing equipment, this kind if defects are getting rear.

Common failures seen in LCDs are a decrease in screen contrast, non-functioning pixels or the whole display, and broken glass. Different kinds of LCD display problem need to have different kinds of fix methods or make the decision not worthwhile to repair.

Broken glassIf you accidently drop the LCD and you find it broken on the surface but the display still works. You might just break the touch panel; you can find a repair house or find a youtube video to replace the touch panel. If you find the display not showing, especially you find the fluid leaking out. You need to reply the whole display modules.

Dim LCD displayLCD can’t emit light itself. It uses backlight. Normally, the backlight is not fully driven, you can increase the LED backlight to make a dim LCD display brighter. But if you LCD display has been used for a long time, it is possible that the LED backlight has to be the end of life (not brightness enough) if you turn on 100% backlight brightness. In that case to fix LCD screen, you have to find a way to change the backlight. For some display, it is an easy job but it can be difficult for other displays depending on the manufacturing process.

LCD has white screen – If a LCD has a white screen which means the backlight is good. Simply check your signal input sources which are the most causes. It can also be caused by the display totally damaged by ESD or excess heat, shock which make the LCD controller broken or the connection failure which has to be repaired by professionals.

Blur ImagesAs the LCD images are made of RGB pixels, the screen shouldn’t be blur like old CRT displays. If you do see blur images, they might be caused by two reasons. 1) LCD has certain response time, if you are playing games or watch fast action movies, some old LCD displays can have image delays. 2) The surface of the LCD is made of a layer of plastic film with maximum hardness of 3H. If you clean the surface often or use the wrong detergent or solvent which cause the surface damage. To fix damage on LED screen it’s need to be changed with professionals.

If you have any questions about Orient Display displays and touch panels. Please feel free to contact: Sales Inquiries, Customer Service or Technical Support.

There’re more than 300 procedures to produce TFT LCD. The most advanced LCD, in which the array and cell process are highly automatic. Technically, every step in the process can lead to defects, and most of the defects have been eliminated through the development of TFT LCD technology.

In LCD, newton’s rings may occur on screen when two glass substrate haven’t been sealed well, so that one of the glass may form a convex lens and lead to light interference.

We also know that a damaged screen can impact your visitors’ experience or even delay an upcoming event. To help you move forward, we execute LED panel repairs quickly and efficiently. We complete repairs for various industries, such as broadcast, education, stadiums, and corporate organizations.

Affordable service contracts are available, so you can keep up with routine maintenance for your LED panels. We can also step in and perform repairs as needed.

Try using lcd panel repair acf found on Alibaba.com to make many types of production jobs faster and easier. Each model can be filled with different types of liquid and quickly dispensed into containers. Use lcd panel repair acf to fill paint cans with speed and precision. Other compatible fluids include resin or glue, making such devices suitable for manufacturing all kinds of helpful products.

All lcd panel repair acf are built to be easy to operate, reducing labor and training times needed. Some versions can pour food-grade liquids such as beer or milk into bottles for future sealing. Most units work automatically so workers can program them and stay back as they work on their own. When installed on a factory floor, they offer greater efficiency to help save time and costs.

Shop for lcd panel repair acf at Alibaba.com to find many helpful suppliers with a wide range of options that can be ordered. Choose just the right size to fit the intended workspace. Pick a wattage level that promises good speed and power without using too much electricity and driving up costs. Certain designs can dispense products in the form of powder or granules into nearby containers. Use these to package particular powdered food and pharmaceutical ingredients.

Search for lcd panel repair acf on Alibaba.com and enjoy lower costs when working with various liquids or powders. Whether for use in food manufacturing or building materials, there are plenty of options to browse. Find a satisfactory brand that will improve efficiency for better overall quality in each final product.

Another type of lcd display replacement machine is the lcd screen replacing, which isip to repair the LCD oractins during a manufacturing process. Lcd display replacer is also available for lcd display quicker, quieter, and less resistant to screen damage.

Typically, lcd display repair icons are available at wholesale prices. With lcd display repair machines, such as mini lcd screen repair machines, which are not suitable for regular users and are looking for a new option. L touch display repair machines with the touchscreen capabilities are the perfect option as a normal one.

One of the different options is the iPhone Xs 11, lcd screen repair machine, or iPhone Xs 11, lcd screen is perfect for a number of different and.- a lcd display repair kit is suitable for a number of different, and one-of-a-kind processes. No matter what lcd screen repair kit is used for, iPhone Xs 11, and one-of-a-kind, are all available to choose from. Lcd display repair kit, suitable for all models of the brands, and one-of-a-kind, for example, is not a good option for iPhone Xs 11, lcd screen repair machine, or any other type of lcd display repair kit. suitable for all lcd models and are available with lcd screen repair kits, and one-of-a-kind.

Unlike older cathode ray tube (CRT) displays that scan an electron beam over a phosphor screen to create light, LCD displays are composed of a fixed grid of tricolor pixels that change transparency based on a range of voltage levels provided by the monitor"s controller. Without a voltage the pixel is opaque and blocks the screen"s backlight from transferring through it, and when a full voltage is applied then the pixel allows full transmittance of the backlight. When this is done over the entire pixel grid in patterns, then you see those patterns on the screen.

This pixel-based setup for LCD monitors provides many advantages over CRT displays, but does have potential drawbacks arising from the fact that the image is dependent on millions of independent electrical components as opposed to a single scanning beam, so if faults occur in these components then the display output can be affected. The resulting problems include stuck or dead pixels, as well as a residual image effect.

One of the more common problems with LCD displays is the potential for stuck or broken pixels, where the pixel either does not receive a voltage and remains black, or does not respond to voltage changes and stays at a set luminance level. Sometimes this can happen for individual pixels, suggesting a problem with the pixel itself, or it can happen to groups of pixels, suggesting the possibility of problems with the display"s controller or a defect in a portion of the pixel grid.

LCD monitors can also be affected by another problem called "transient persistence" that is reminiscent of CRT burn-in. Classic burn-in would happen because the phosphor coating on the screen would get depleted by the persistent bombardment of electrons from the CRT, resulting in the inability of those sections of the display to convert the electron beam to visible light. This meant that if you kept a specific pattern showing on the screen then over time it could become a permanent residual image on the display that would show even when the display was turned off. This was a reason why screensavers were developed--to keep the wear on the screen"s phosphor coating as even as possible.

The physical burn-in of displays is no longer an issue now that LCD displays have taken over, but while transient image persistence is not a physical burn of the device, it is an alteration of the pixel response to voltage changes (usually temporary) that prevents pixels from getting as bright as others on the screen.

Similar to CRT burn-in, LCD image persistence generally happens after you have displayed a pattern of intense colors on screen; however, unlike CRT burn-in, LCD persistence can sometimes set in after only a few hours of displaying the image, as opposed to the weeks or even months that it can take for burn to set in on a CRT monitor. Additionally, unlike CRT burn-in, image persistence can often be reversed.

What happens with LCD monitors is the affected pixels have lost their ability to respond to the full range of voltages that the display gives them, resulting in a limited range of colors that can be output. This can happen if the pixel is acting like a capacitor and is retaining a residual charge, or if it is not able to reach the level of luminance that is desired when given a specific voltage. Either way, the pixel is not able to reach its full range of possible intensities.

Unlike stuck or dead pixels that may benefit from having the monitor turned on and off rapidly to produce rapid voltage changes, image persistence will benefit from a lengthy stretching of the pixel"s range. Therefore, instead of using tools like JScreenFix to run random patterns over the affected screen area, you might instead place a pure white window (such as an empty TextEdit window, or what you get using the "White" option in the LCD Repair tool listed above) over the affected area for a few hours or even a few days if necessary. Doing this will force those pixels to be fully on, and over time their intensities may increase to be the same as the surrounding pixels.

Likewise, try turning off the pixels fully by shutting down the display for a long period of time or placing a pure black texture over the affected area (see the LCD Repair tool listed above for this option as well). This will turn the pixels completely off and allow residual voltage in them to drain slowly over time.

So far we have discussed pixel-based problems with LCD displays, but the system"s backlight can also suffer some common problems that include the backlight randomly blinking off, not turning on, or only illuminating part of the screen.

If only the backlight is malfunctioning, then the LCD panel itself should still be working just fine and should be rendering the text and images of your computer"s output. To test for this, use a bright flashlight and shine it on your screen at an angle in an area where you expect images and text to be (such as the Dock or menu bar). On Apple"s laptop systems, you can shine the flashlight through the Apple logo on the back to illuminate the screen on the front and better detect text and images that way.

Black screens appear in the daily work of industrial LCD screens, what should we do? Don’t worry. black screen fault treatment method. Today, we summarize the reasons for the black screen fault treatment method by the failure of industrial LCD screens:

Check whether the power indicator on the host chassis panel is on and whether the power fan is rotating to determine whether the host system is supplied with power. Secondly, the multimeter is used to check whether the external voltage meets the requirements. If the voltage is too high or too low, it may cause the automatic shutdown protection of the main-machine power supply with overvoltage or Undervoltage.

When the Industrial LCD display is powered up, there is a click sound, and the LCD’s power indicator lights up. When users move to the LCD screen, there is a hissing sound, and hairs on the back of their hands stand up.

If the Industrial LCD screen and speakers within the host let out a long and a short hum industrial LCD screen indicates display card and the connection between the mainboard has a problem, or display card and display this connection has a problem, can be the key to check whether the slot contacts good whether there is a foreign body inside the tank, the display card in a motherboard slot for testing, to determine whether there is something wrong with the slot.

NDSsi uses only “Grade A” LCD panels in all of its products, while many competitors use “Grade B” panels in order to save cost, and as a result compromise quality. In medical applications, it is important not to compromise the quality of the displayed image since it is often the basis for making clinical decisions. The following tables and images show the differences between “Grade A” and “Grade B” LCD panels in terms of different types of allowable defects.

There are essentially two different types of pixel defects, bright (stuck pixels) and dark (dead pixels).The table and images below show the differences between Grade A and Grade B LCD panels in terms of allowable pixel defects.

This is a general Wiki to describe the most commonly found boards inside a LCD TV. The boards are common to most TV’s but there are manufacturers and models that may either have a variation of the boards or added additional boards for further function. Those would have to be assessed and evaluated by utilizing the service manual for the specific model.

When the Main Board receives the 5V standby voltage from teh power supply board, it will be routed through a voltage regulator IC or DC-DC circuit to generate a 3.3V voltage. The 3.3V will be supplied to the MCU (microcontroller unit) IC, CPU and the Front Panel board. Now we can see the standby LED light is lit and the TV is in the Standby Mode now.

Once the back panel is removed from the TV now, each type of flat panel TV will have a distinct set of parts. LCD TV’s typically contain these circuit boards:

define what a power supply is and you will most likely get a response such as ‘that box plugged into the mains that powers my equipment’. That’s the function but what it’s doing is very complex. It’s taking raw AC from the mains, normally compatible with any supply voltage in the world (with its tolerances, dips and spikes) and converting it to a stable lower DC voltage. It will incorporate a feedback loop to keep the output voltage constant with changes in input voltage and output load current. Fast load steps will be reacted to within a designed control loop response time with minimal consequential output voltage transients. It will provide safety isolation to the highest statutory level for the highest standard mains voltage and will remain safe to a minimum level, even with a single component failure. It will have controlled radiated and conducted noise emissions to statutory levels and be immune to noise from other sources. A good design will have various levels of protection against single internal faults that might potentially cause output over- voltage, chains of multiple component failures, excessive temperatures, electric shock or even fire.

1. Through the CPU and MCU (microcontroller unit) processors it controls the system via multiple signals. For example it is the main board that tells the power board to turn on the backlight; it tells the panel when to turn on/off etc.

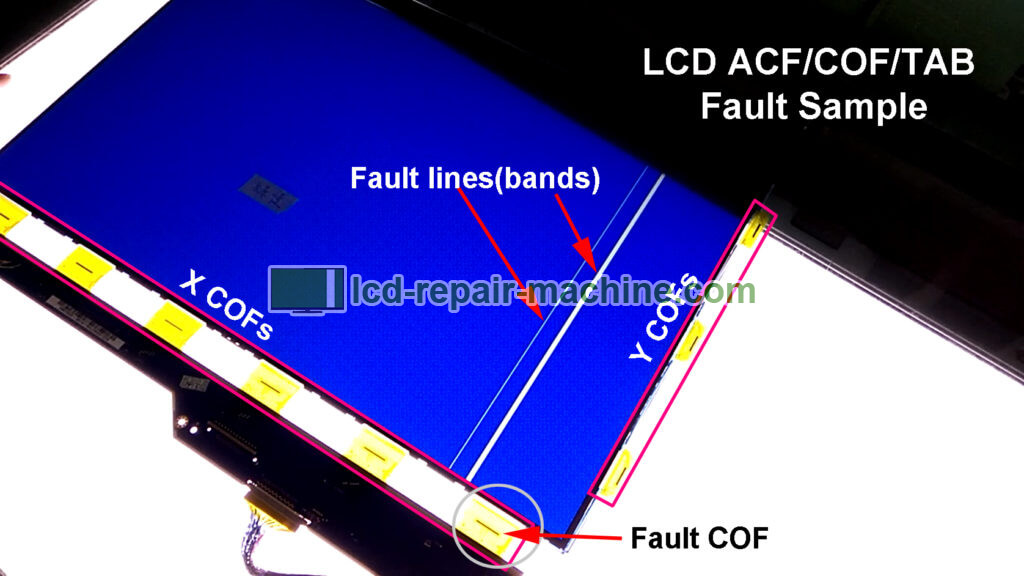

Since 2014 VEE FIX INDIA has focused in the field of LCD Panel repairing technology by setting up research and development center to enhance ACF / TAB / FPG / COF/ FOG bonding process.

1. We started investigating this malfunction with the LCD module supplier, and with the module manufacturer in May, 2018. During the investigation, the LCD panel manufacturer went out of business before the final conclusion of the cause of the LCD panel failures. Without the assistance of the LCD panel manufacturer, the true cause of the LCD panel failures could not be identified.

IMHO, I find this statement to be severely lacking in comprehensive and verifiable facts that explain how ICOM"s Failure Review Team"s identified Root Cause when the supplier went bankrupt before the true cause of the LCD panel failures could be identified.

3. After the LCD panel manufacturer’s bankruptcy, our only resolution was to find a new LCD panel manufacturer capable of meeting the current radio design specifications. Upon finding a new manufacturer, thorough testing was done to make sure the IC-7610 would meet our original design specifications, as well as a burn-in test to make sure the “Image Retention” condition would not occur again.

IMHO this statement is most critical in revealing how the test milestone was achieved bringing on a new supplier. For example; to achieve a successful burn-in test for a new LCD supplier, you would subject a small sample of their LCDs to a long term 24/7, 12,000 hours burn-in test. This fact will help explain why the process is taking so long. Not making excuses for ICOM, just looking at this for what it is.

Especially knowing that identification for Root Cause could not be completed working with the supplier who went bankrupt before the true cause of the LCD panel failures could be identified.

4. The selection of the final LCD panel manufacturer is complete. As we introduce this new module for production, as well as for warranty replacement, there will be an additional testing phase to make sure these displays meet all our specifications. We are coordinating replacement quantities, as well as a delivery schedule, with the LCD module supplier for the quickest schedule possible for components for replacement of failed LCD modules.

IMHO, I translate this to mean; "Our New Supplier will need more time to ramp up production to meet ICOM delivery requirements which is longer that I am willing to advertise to my customers.Or, I have no confidence in my burn-in test or my conclusions were I stated that the failure was related to the LCD panel, not other sections of the radio design.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey