vex lcd display manufacturer

We have thousands of standard products that are in stock and available from our Seattle, WA and Hong Kong warehouses to support fast product development and preproduction without MOQ. The stock covers TN, STN LCD display panels, COB, COG character LCD display, graphic LCD display, PMOLED, AMOLED display, TFT display, IPS display, high brightness and transflective, blanview sunlight readable display, super high contrast ratio display, lightning fast response displays, efficient low power consumption display, extreme temperature range display, HMI display, HDMI display, Raspberry Pi Display, Arduino display, embedded display, capacitive touch screen, LED backlight etc. Customers can easily purchase samples directly from our website to avoid time delays with setting up accounts and credit terms and shipping within 24 hours.

Many of our customers require customized OEM display solutions. With over two decades of experience, we apply our understanding of available display solutions to meet our customer’s requirements and assist from project concept to mass production. Using your ideas and requirements as a foundation, we work side by side with you to develop ideas/concepts into drawings, build prototypes and to final production seamlessly. In order to meet the fast changing world, we can provide the fastest turnaround in the industry, it takes only 3-4 weeks to produce LCD panels samples and 4-6 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen samples. The production time is only 4-5 weeks for LCD panels and 5-8 weeks for LCD display module, TFT LCD, IPS LCD display, and touch screen.

New Vision Display is a custom LCD display manufacturer serving OEMs across diverse markets. One of the things that sets us apart from other LCD screen manufacturers is the diversity of products and customizations we offer. Our LCD portfolio ranges from low-cost monochrome LCDs to high-resolution, high-brightness color TFT LCDs – and pretty much everything in between. We also have extensive experience integrating LCD screen displays into complete assemblies with touch and cover lens.

Sunlight readable, ultra-low power, bistable (“paper-like”) LCDs. Automotive grade, wide operating/storage temperatures, and wide viewing angles. Low tooling costs.

Among the many advantages of working with NVD as your LCD screen manufacturer is the extensive technical expertise of our engineering team. From concept to product, our sales and technical staff provide expert recommendations and attentive support to ensure the right solution for your project.

In addition, our extensive technology portfolio and manufacturing capabilities enable us to deliver high-quality products that meet the unique specifications of any application. To learn more about what makes us the display manufacturer for your needs, get in touch with us today.

As a leading LCD panel manufacturer, NVD manufactures custom LCD display solutions for a variety of end-user applications: Medical devices, industrial equipment, household appliances, consumer electronics, and many others. Our state-of-the-art LCD factories are equipped to build custom LCDs for optimal performance in even the most challenging environments. Whether your product will be used in the great outdoors or a hospital operating room, we can build the right custom LCD solution for your needs. Learn more about the markets we serve below.

Products»All Products»Power & UPS»Batteries & Ultracapacitors»Standard DC-DC Power»Smart DC-DC Power»Smart Battery Chargers»Galvanically Isolated Power Supplies»24V Output Supplies»Ultracapacitor Chargers»Adjustable Output Power Supplies»Universal Chargers»Uninterruptible Power Supplies»Embedded Boards»I/O & Communication»Embedded CAN bus Modules»Embedded Ethernet Switches»Embedded Digital IO Modules»Embedded Analog IO Modules»Embedded Serial IO Modules»PCIe Mini Cards»Embedded Power Supplies»Standard Embedded Power»Smart Embedded Power»PC/104 Power Supplies»Embedded UPS Modules»Embedded Motherboards»PC/104 Motherboards»ETX Motherboards»COM Express Motherboards»EPIC Motherboards»EBX Motherboards»Mini-ITX Motherboards»Micro-ATX Motherboards»Industrial ATX Motherboards»Embedded GPS Modules»GPS Receiver Modules»Embedded GPS Antennas»CPU Boards & SBC»PC/104 SBC»EPIC SBC»ETX SBC»EBX SBC»Mini-ITX SBC»ARM CPU Modules»Micro-ATX SBC»Embedded ATX SBC»Com Express SBC»Embedded Ultracapacitor Modules»Embedded Battery Modules»Embedded Video Cards»Systems»Fanless Box PC»Wide Temperature»Industrial Automation Computers»Rugged Vehicle Computers»Railway Computers»Vehicle Tracking Systems»Industrial Rackmount Computers»Wide Temperature Systems»Digital Displays»Marine Monitors»Rugged LCD Displays»Wide Temperature LCD Displays»Waterproof LCD Panels»Advertising LCD Displays»Stretched Bar LCD»Sunlight Readable LCD Displays»Public Transportation LCD Displays»Railway LCD Displays»Outdoor LCD Displays»High Brightness LCD Displays»Extended Temperature LCD Displays»Industrial Monitors»Panel Computing»Marine Panel PC»Infotainment Panel PC»Wide Temperature Panel PC»HMI Panel PC»Modular Panel PC»Mobile Computing»Rugged Tablets»Rugged Windows Tablets»Rugged Android Tablets»Rugged PDA»Antennas»GPS Antennas»External GPS Antennas»Passive GPS Antennas»Active GPS Antennas»Marine GPS Antennas»Internal GPS Antennas»GNSS Antennas»GLONASS Antennas»Multi-Band Antennas»GPS-GLONASS Antennas»Iridium Antennas»GPS & RF Signal Distribution»GPS Amplifiers»Low Noise Amplifiers»GPS Receivers»Marine GPS Receivers»GPS Attenuators»GPS Combiners»GPS Splitters»Active GPS Splitters»Military GPS Splitters»Rackmount GPS Splitters»Passive GPS Splitters»Repeaters»GPS Repeaters»GLONASS Repeaters»GPS Filters»Enclosures & Chassis»PC/104 Chassis»Rugged Mini-ITX Cases»EPIC Enclosures»EBX Enclosures»Memory & Storage»Memory»Flash Storage»Industrial SSD»SATA Disk On Modules»Industrial Micro SD Cards»Industrial SD Cards»Industrial CompactFlash Cards»Sensors»Industrial Networking»Manufactured by Tri-M»Power & UPS»Standard Power Supplies»HE104: 60 Watt»HE104-DX: 60 Watt»HE104-75W: 75 Watt»HE104+DX: 108 Watt»HE-HP: 100 Watt»Smart Power Supplies (PowerOS)»HESC-SERD: 60 Watt»HESC104+: 108 Watt»HPS3512: 203 Watt»HPSP-XYZ: 240W Programmable»V12SC-SER[-UPS]»TPS1000: 35 Watt, 42 Watt»TPSi1075: 75 Watt, Isolated»TPSi1085: 85 Watt, Isolated»HPSC104-SER: 160 Watt»HESC104: 60 Watt»TPS1035»TPC1000»HPS3524»Smart UPS (PowerOS)»TUP1000: Ultracapacitor UPS»V5SC-SER-UPS: NiMh Battery UPS»UltraUPS»V12SC-SER[-UPS]»Ultra Capacitor Packs»TBP4xxx»Battery Backup Packs»BAT-NiMh45»BAT104-NiMh»BAT104-NiCd»BAT-SLA(25/45)»UltraUPS»Heavy Duty Transient Stopper»CPU Modules»I/O & Communication»Input / Output»IO104-60IN: PC104 I/O Board»IR104 PC/104 Relay Module»Communication»TCB1000 PC/104 Com Board»FlexCom104-GPS»Enclosures»VersaTainer: PC104 & EBX»CanTainer: PC104»FlexTainer: EPIC, MITX, EBX»GPS & Networking»GPS & Networking Boards»FlexCom104-GPS»Antennas»Mighty Mouse: Small GPS Antenna»Micro Mouse: Micro GPS Antenna»Big Brother»Re-Radiators»Super-Radiator»Xtreme-Radiator»Vehicle GPS Repeater»Complete System Solutions»HECS1000 System»UltraUPS Complete Backup Solution»Support Products & Accessories»PC104-T AC Termination Modules»Extract104»TS-I2C Temperature Sensor»DA104»VSX-2812 Video Modules»ISA104X1»Postcode104»Legacy Products»Distributed by Tri-M»Diamond Systems»Single Board Computers»Aurora PC/104 SBC»Helios PC/104 SBC»Neptune EPIC SBC»Pluto ETX SBC»Hercules III EBX SBC»IEI»IEI Mobile»MicroMax Computer Intelligence»San Jose Technology (SANAV)»GNSS Repeaters»RK-306»RK-106»Innodisk»GPS Networking»Litemax»Spanpixel»Durapixel»Navpixel»Aaeon Electronics»Systems»Fanless Embedded Computers»Entry-Level Box PC»ICOP Technology»ICOP-2811»VDX2-6554»VEX-6254»VSX-2812S»86Duino Enjoy Desktop 3D Printer»MPLSelector Guides»Power Selector Guide»Backup Power SelectorServices»Conformal Coating»HumiSeal 1B31»Laser Engraving & EtchingTri-M Rugged»PowerOS»Mining Applications»Mining Application Story»Rail & ITS Applications»Automation & Manufacturing»Mil-Aero Defence & Aerospace»Aerospace Application StorySupportAbout Us»About Us»Privacy PolicywebstoreTriple Programmable PSUQuote Request

Kingtech is one of the leading TFT LCD display OEM/ODM manufacturers in China since 2003. Customization is allowed for projects such as industrial devices, medical, POS, logistics devices, smart home applications and etc.

To provide a one-stop LCD display solution. During the last 17 years, based on LCD manufacturing as our center, we gradually expand to the TFT capacitive touchscreen, driving board, software hardware design, and complete industrial computer solution.

As a professional LCD screen supplier/ LCD display supplier/ LCD panel company/ LCD module manufacturer, Kingtech LCD aims to provide a one-stop service and solve your problems. With a strong LCD Display module R & D team and strict quality management of IS09001, IS01400ATF16949 certificates.

We love the LCD screen. Really. It is one of our favorite tools. Here’s a more technical run-down of the uses that the girls mention in their STEM Educational Video that they entered this week in the REC Foundation’s 2017 Online Challenge.

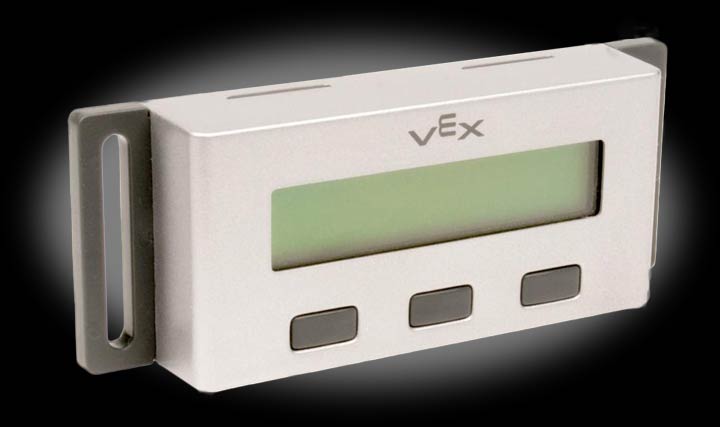

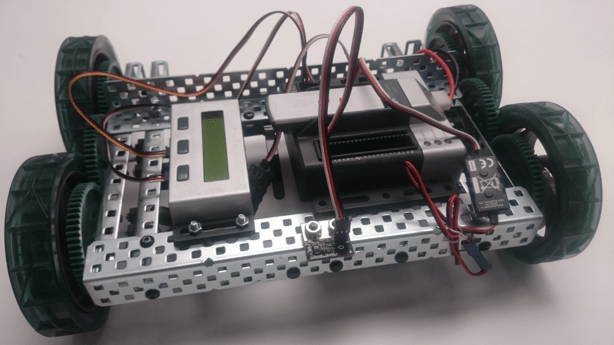

First, you need to buy yourself an LCD screen, and a Serial Y Cable. NOTE: the cable does not come with the screen, even though it seems like it should. You must buy it separately. You can use up to 2 LCD screens on your robot at one time, though honestly I’ve never seen anyone use 2.

Plug the 4-prong end of the Y-cable into either UART1 or UART2 on the Cortex (remember which one you use; convenient to always use UART1, unless you have a specific reason not to). This plug is over on one corner of the Cortex, near where motor encoders get plugged in. You’ll plug the other wires into the LCD screen. We have a little mnemonic to remember which wires go into which plug: whiTe goes into TX (over-emphasize the “T” when you say “white”), and yell-ER goes into RX (pronouncing “yellow” with a southern drawl). If they are plugged in backward, it will not work.

Make sure your kids install the LCD on the robot (a) where it’s easily accessible to read the screen and press the buttons, and (b) also protected from being struck by game elements or other robots.

(Much of this programming information is in easyC, because that’s what we used at the time of this writing. The exact function names used in RobotC can be found on the RobotC help page, under Command Library – VEX Cortex / ROBOTC / LCD Display.

As a first test to make sure your screen is working, include in your program (autonomous, joystick, or competition) a line of code that just displays a message, and does nothing else. You’ll need to initialize the LCD screen at the start of the program, and somewhere before you have the message display, it’s helpful to make the back-light turn on.

In EasyC, you need to use one LCD display block for each line of the LCD screen that you want to use. Drag over a block and enter the text for your Line 1 message, and leave all of the other stuff blank (the stuff related to variables, etc.); do the same for Line 2 if you’re using it. NOTE: If you put a message on Line 2, and later in your program display a different message, but only use Line 1 at that time, the Line 2 text will remain on the screen unless you specifically drag over a block and tell Line 2 to display a blank line.

If your robot is tethered to your computer, you can use the print-to-screen function to display sensor (or variable) values, but that covers about 1% of the situations where you want to know what a sensor value is. Most of the time, you’re in a joystick/competition program, or your robot is moving around the field, and you cannot be tethered to the computer, or it’s just not realistic.

Enter the LCD screen! You can put somewhere in your Main() loop a get command to get the latest sensor value and then an LCD command to display it on the screen. If it’s a variable you’re after, just make sure that the LCD display command is somewhere after the variable is being calculated.

Beware! Each line of the LCD screen can only hold 16 characters. If you give it text that’s 14 characters, plus a 3-digit sensor value, the LCD will show you the first 2 digits of your sensor value, and will just cut off/not display the 3rd digit. So you may think that you’re getting sensor data just fine, but at some point it will look like the numbers wrap around and restart their numbering at 0 again. It will look like it has wrapped around to, say, “11”, when the sensor value is really 110.

Beware some more (RobotC users)! When displaying sensor values on the screen—especially in a while loop—be sure to clear the existing text before displaying the sensor’s value. We were trying to calibrate our gyro sensor recently, and when we turned the robot around 360º, the value in RobotC is supposed to reset to 0, but on our robot, once we passed 3599 (the gyro reports values in tenths-of-a-degree, so 360º = 3600), it would jump to 1599, and then if we kept turning it, the values got ridiculously huge—3299, 9099, etc. Whaaaaa??? After half of a meeting devoted to this problem, we realized that once we passed 0, it was in fact displaying the new degree values, starting in the left-most position on top of what was already there, so what we were reading as 1599 was really a sensor value of 15, written on top of the previous value of 3599. So we added a line of code inside the while loop to clear the first line of the LCD display and then write the sensor value. (This appears to be only a RobotC problem; easyC is fine with the blocks of code shown above, without an extra block for clearing the line.)

One other use where we find the LCD to be valuable is debugging our programs. There are many times when a program is not working, and you just can’t figure out what is actually executing in the code. You’ve got some code that seems like it should be doing the right thing, but nothing is happening.

You could put different messages in different sections of your code, but be aware that a joystick program is looping through rapidly, and if you have Message1 display when x happens, and then Message2 display when y happens, Message1 may display for a tiny fraction of a second, and then be over-written by Message2. It’s good to stick with at most 2 non-exclusive messages, each of which occupies one line of the LCD screen (so that they can both display at the same time if necessary).

Our FAVORITE use of the LCD is as a little menu-selector to choose an autonomous program during a competition. If you’ve got an autonomous program that involves moving left or right, you’ve undoubtedly got 2 of them, depending on what square your robot starts in. In one scenario it’ll need to move left, but if it starts in the other colored starting square for that alliance team, it’ll need to move right.

Without the LCD screen, your team needs to find their alliance partner, decide who’s going to start where (and communicate clearly what they mean by “start on the left square,” for example), and then go back to the pits and load the correct program onto the robot. Let me tell you how many times I have seen this result in the wrong program on the robot—20% of the time, maybe? Your team could lose a match without those autonomous points, and it’s incredibly frustrating for the kids to have their perfect code work backward when the clock starts. So why not remove 99% of human error and have a little menu selector on the robot itself! That way your team never has to load a program on the robot all day long at a competition. We even include our programming skills challenge code as one of the menu items, so we rarely have to open up the computer at a tournament.

You can download EasyC code (or pseudo-code) on our downloads page that will get you started creating your own menu (full credit goes Ephemeral_Being from the VEX forum for writing this code). Important notes, as the girls mention in their video:

Edit 7/2/18: Here’s a very clear and helpful YouTube tutorial on programming your own auton menu selector in easyC. There are many RobotC examples of this type of code on the VEX Forum; a simple search will find some for you. You can also read my detailed post that walks you through how Ephemeral Being’s code works.

Established in 1998, Winstar Display Co., Ltd. is a reliable LCD Display Module Manufacturer and LCD Panel Supplier. Winstar has development of high-quality display module products. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively. We provide LCM Modules including monochrome TN/STN/FSTN LCM, COG LCD, TFT LCM / TFT panels, FSC-LCD, graphic LCM, character LCD displays, OLED display modules (PMOLED), custom LCD displays, OLED and LCD panel.

STONE Technologies is a proud manufacturer of superior quality TFT LCD modules and LCD screens. The company also provides intelligent HMI solutions that perfectly fit in with its excellent hardware offerings.

STONE TFT LCD modules come with a microcontroller unit that has a 1GHz Cortex-A8 CPU. Such a module can easily be transformed into an HMI screen. Simple hexadecimal instructions can be used to control the module through the UART port. Furthermore, you can seamlessly develop STONE TFT LCD color user interface modules and add touch control, features to them.

You can also use a peripheral MCU to serially connect STONE’s HMI display via TTL. This way, your HMI display can supply event notifications and the peripheral MCU can then execute them. Moreover, this TTL-connected HMI display can further be linked to microcontrollers such as:

Becoming a reputable TFT LCD manufacturer is no piece of cake. It requires a company to pay attention to detail, have excellent manufacturing processes, the right TFT display technology, and have a consumer mindset.

Now, we list down 10 of the best famous LCD manufacturers globally. We’ll also explore why they became among the top 10 LCD display Manufacturers in the world.

Interface Devises Business includes Display and Senor, Sensor, and Application Solutions. As a leading company in the global semiconductor display industry, BOE has made the Chinese display industry develop from scratch to maturity and prosperity. Now, more than one-quarter of the global display panels are made by BOE, with its UHD, flexible display, microdisplay, and other solutions broadly applied to well-known worldwide brands.

LG Display is a leading manufacturer of thin-film transistor liquid crystal displays (TFT-LCD) panels, OLED, and flexible displays.LG Display began developing TFT-LCD in 1987 and currently offers Display panels in a variety of sizes and specifications using different cutting-edge technologies (IPS, OLED, and flexible technology).

LG Display now operates back-end assembly plants in South Korea, China, and Vietnam. In addition, LG Display operates a sales subsidiary with a global network to effectively serve overseas markets.

With innovative and differentiated technologies, QINNOOptoelectronics provides advanced display integration solutions, including 4K2K ultra-high resolution, 3D naked eye, IGZO, LTPS, AMOLED, OLED, and touch solutions. Qinnooptoelectronics sets specifications and leads the market. A wide range of product line is across all kinds of TFT LCD panel modules, touch modules, for example, TV panel, desktop and laptop computer monitor with panels, small and medium scale “panels, medical, automotive, etc., the supply of cutting-edge information and consumer electronics customers around the world, for the world TFT – LCD (thin-film transistor liquid crystal display) leading manufacturers.

AU Optronics Co., LTD., formerly AU Optronics Corporation, was founded in August 1996. It changed its name to AU Optronics after its merger with UNIOPtronics in 2001. Through two mergers, AU has been able to have a full range of generations of production lines for panels of all sizes.Au Optronics is a TFT-LCD design, manufacturing, and r&d company. Since 2008, au Optronics has entered the green energy industry, providing customers with high-efficiency solar energy solutions.

Sharp has been called the “father of LCD panels”.Since its founding in 1912, Sharp developed the world’s first calculator and LIQUID crystal display, represented by the living pencil, which was invented as the company name. At the same time, Sharp is actively expanding into new areas to improve people’s living standards and social progress. Made a contribution.

BYD IT products and businesses mainly include rechargeable batteries, plastic mechanism parts, metal parts, hardware electronic products, cell phone keys, microelectronics products, LCD modules, optoelectronics products, flexible circuit boards, chargers, connectors, uninterruptible power supplies, DC power supplies, solar products, cell phone decoration, cell phone ODM, cell phone testing, cell phone assembly business, notebook computer ODM, testing and manufacturing and assembly business, etc.

From the introduction of Japan’s original washing machines, refrigerators, and other household appliances, to the world’s first laptop, the first 16MB flash memory, the world’s smallest 0.85-inch HDDs; Create advanced HDDVD technology; Toshiba created many “world firsts” in the research and manufacture of new SED displays and contributed to changing people’s lives through constant technological innovation.

Tianma microelectronics co., LTD., founded in 1983, the company focus on smartphones, tablets, represented by high order laptop display market of consumer goods and automotive, medical, POS, HMI, etc., represented by professional display market, and actively layout smart home, intelligent wear, AR/VR, unmanned aerial vehicles (UAVs) and other emerging markets, to provide customers with the best product experience.IN terms of technology, the company has independently mastered leading technologies such as LTPS-TFT, AMOLED, flexible display, Oxide-TFT, 3D display, transparent display, and in-cell/on-cell integrated touch control. TFT-LCD key Materials and Technologies National Engineering Laboratory, national enterprise Technology Center, post-doctoral mobile workstation, and undertake national Development and Reform Commission, The Ministry of Science and Technology, the Ministry of Industry and Information Technology, and other major national thematic projects. The company’s long-term accumulation and continuous investment in advanced technology lay the foundation for innovation and development in the field of application.

The VEX ARM® Cortex®-based Microcontroller coordinates the flow of all information and power on the robot. It has built in bi-directional communication for wireless driving, debugging and downloading using the VEXnet wireless link. The Microcontroller is the brain of every VEX robot.

VEXnet devices contain internal processors and run on special software called Firmware (or Master Code). Firmware is updated periodically to provide additional functionality or fix bugs. To fully unlock the potential of VEX Robotics VEXnet devices, it"s important to ensure that all applicable drivers are installed and firmware is updated.

Flat-panel displays are thin panels of glass or plastic used for electronically displaying text, images, or video. Liquid crystal displays (LCD), OLED (organic light emitting diode) and microLED displays are not quite the same; since LCD uses a liquid crystal that reacts to an electric current blocking light or allowing it to pass through the panel, whereas OLED/microLED displays consist of electroluminescent organic/inorganic materials that generate light when a current is passed through the material. LCD, OLED and microLED displays are driven using LTPS, IGZO, LTPO, and A-Si TFT transistor technologies as their backplane using ITO to supply current to the transistors and in turn to the liquid crystal or electroluminescent material. Segment and passive OLED and LCD displays do not use a backplane but use indium tin oxide (ITO), a transparent conductive material, to pass current to the electroluminescent material or liquid crystal. In LCDs, there is an even layer of liquid crystal throughout the panel whereas an OLED display has the electroluminescent material only where it is meant to light up. OLEDs, LCDs and microLEDs can be made flexible and transparent, but LCDs require a backlight because they cannot emit light on their own like OLEDs and microLEDs.

Liquid-crystal display (or LCD) is a thin, flat panel used for electronically displaying information such as text, images, and moving pictures. They are usually made of glass but they can also be made out of plastic. Some manufacturers make transparent LCD panels and special sequential color segment LCDs that have higher than usual refresh rates and an RGB backlight. The backlight is synchronized with the display so that the colors will show up as needed. The list of LCD manufacturers:

Organic light emitting diode (or OLED displays) is a thin, flat panel made of glass or plastic used for electronically displaying information such as text, images, and moving pictures. OLED panels can also take the shape of a light panel, where red, green and blue light emitting materials are stacked to create a white light panel. OLED displays can also be made transparent and/or flexible and these transparent panels are available on the market and are widely used in smartphones with under-display optical fingerprint sensors. LCD and OLED displays are available in different shapes, the most prominent of which is a circular display, which is used in smartwatches. The list of OLED display manufacturers:

MicroLED displays is an emerging flat-panel display technology consisting of arrays of microscopic LEDs forming the individual pixel elements. Like OLED, microLED offers infinite contrast ratio, but unlike OLED, microLED is immune to screen burn-in, and consumes less power while having higher light output, as it uses LEDs instead of organic electroluminescent materials, The list of MicroLED display manufacturers:

Sony produces and sells commercial MicroLED displays called CLEDIS (Crystal-LED Integrated Displays, also called Canvas-LED) in small quantities.video walls.

LCDs are made in a glass substrate. For OLED, the substrate can also be plastic. The size of the substrates are specified in generations, with each generation using a larger substrate. For example, a 4th generation substrate is larger in size than a 3rd generation substrate. A larger substrate allows for more panels to be cut from a single substrate, or for larger panels to be made, akin to increasing wafer sizes in the semiconductor industry.

"Samsung Display has halted local Gen-8 LCD lines: sources". THE ELEC, Korea Electronics Industry Media. August 16, 2019. Archived from the original on April 3, 2020. Retrieved December 18, 2019.

"TCL to Build World"s Largest Gen 11 LCD Panel Factory". www.businesswire.com. May 19, 2016. Archived from the original on April 2, 2018. Retrieved April 1, 2018.

"Panel Manufacturers Start to Operate Their New 8th Generation LCD Lines". 대한민국 IT포털의 중심! 이티뉴스. June 19, 2017. Archived from the original on June 30, 2019. Retrieved June 30, 2019.

"Business Place Information – Global Operation | SAMSUNG DISPLAY". www.samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

"Samsung Display Considering Halting Some LCD Production Lines". 비즈니스코리아 - BusinessKorea. August 16, 2019. Archived from the original on April 5, 2020. Retrieved December 19, 2019.

Herald, The Korea (July 6, 2016). "Samsung Display accelerates transition from LCD to OLED". www.koreaherald.com. Archived from the original on April 1, 2018. Retrieved April 1, 2018.

Byeonghwa, Yeon. "Business Place Information – Global Operation – SAMSUNG DISPLAY". Samsungdisplay.com. Archived from the original on 2018-03-26. Retrieved 2018-04-01.

www.etnews.com (30 June 2017). "Samsung Display to Construct World"s Biggest OLED Plant". Archived from the original on 2019-06-09. Retrieved 2019-06-09.

"China"s BOE to have world"s largest TFT-LCD+AMOLED capacity in 2019". ihsmarkit.com. 2017-03-22. Archived from the original on 2019-08-16. Retrieved 2019-08-17.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey