custom round lcd module free sample

1.What advantages do you have?A. Fast delivery time, can support sample services, products are in stock, can be supplied at any time, 24 hours online service, products have passed strict certification, and the buyer has good results.2.Q: How can I get the samples?A: Send inquiry → Offer quotation →Confirm quotation & pay tooling charge → Provide drawing → confirm drawing → make tooling & samples → Samples finished → Delivery via freight or sea collect.3.Q: How long can I expect to get the sample?A: Contour drawing: 2-4 days Sample time: 7-15 days.4.Q: Can you design the lcd in acccordance with our demand?A: Sure.We will give you the best tooling charge.5.Q: How to place orders ?A: If you confirm samples ok, Please send us your purchase order by Email or Fax , Then we will send you an Invoice for deposit payment. We need to know the following information of your order.

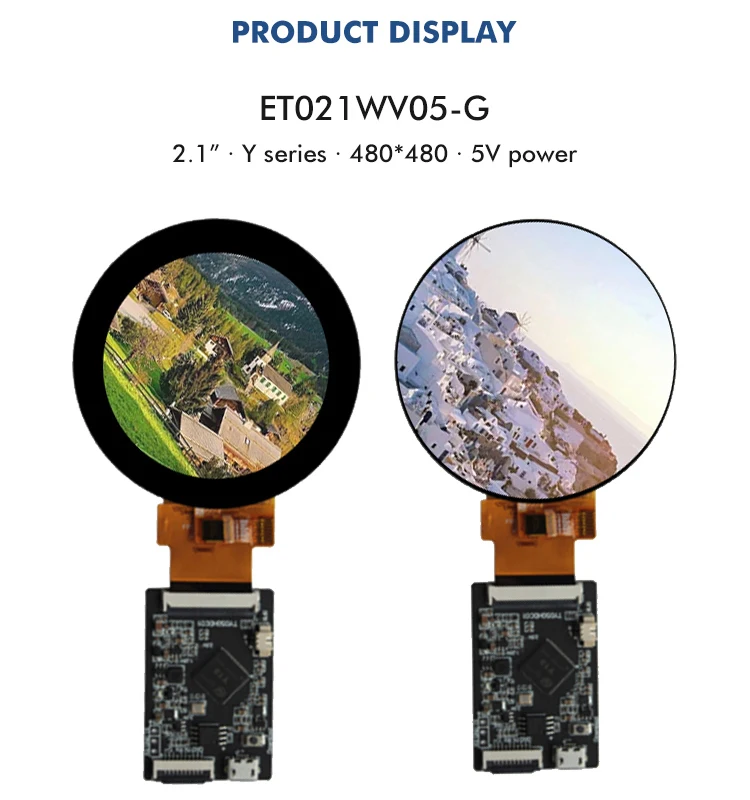

A wide variety of custom round lcd module options are available to you, You can also choose from original manufacturer, odm and agency custom round lcd module,As well as from tft, ips, and standard.

One of the components the wearable watch needs is LCD screen. I have been receiving RFQs of round LCD display module since last year. Let me introduce you the 3 main ways that we make custom round display module.

It is a very common monochrome LCD screen. The pink graphic we see is the silk painting which is printed on the ITO glass. The outer clock is counting the seconds, so the black needle makes a complete turn in 60 seconds; and the inner clock is counting the minutes, so the black needle makes a complete turn in 30 minutes. In the middle of LCD screen, it is a typical 7-segment digital that could count minutes, seconds and 1/100th a second.

The LCD module includes LCD screen, IC, LED backlight (not necessary) and PCB (not necessary). The view area is only 77.0*77.0 mm, the LCD screen is 80.0*82.0 mm, but the whole COB LCD module is 94*105mm.

We use 6 DIP LEDs as the light source of LED backlight, and it needs 10 mm(8 mm at least) light shade area, check the green area of the picture above, that is why it is so big. The PCB is much bigger because there are 4 pieces of radius 1.5 mm screws to fasten the PCB and other devices together.If we put a plastic shell in front of it, it becomes a round LCD. The advantage of this methodology is that it is easiest to make, cheapest, and most stable. But the disadvantage is that the whole size of LCD module is too big. We can find a way to make it much smaller.

How can we make it so small? First, we confirm the view area 77*77 mm. Second, expand it 1.5 mm which is the minimum distance between the edge of LCD screen and view area. Third, expand it by 2.0 mm which is the distance between upper ITO glass and lower ITO glass. I marked the upper and lower ITO glasses with green lines.Fourth, expand it 1.0 mm which is the width and height of walls. Fifth, if I didn’t make a mistake, the LCD screen, LED backlight and PCB should be all round. As we know, LED backlight and PCB can be round, but not LCD screen. If LCD screen is round, what kind of connection should be used? Metal pin, zebra or conductive rubber strip can’t be installed in the round edge. Find the middle point at the bottom of LCD screen, draw a parallel line and move it up 2.5 mm, and we cut it along with the line, that is the edge of PCB. Move it up 1.0 mm and 2.0 mm, that is the edge of LCD screen. Move it up to 1.5 mm, that is the view area.

We finally get the parallel edge where conductive rubber strip or zebra can be installed. We can see that the parallel edge of LCD is only 25 mm. But how many segments do we have? 60 seconds segments + 30 minutes segments + 6*typical 7-segment digitals=132 segments. Duty is 1/4, 132/4+4=37 pieces of legs. There are 4 commonly used types of pitches for PINs: 1.27 mm, 1.5 mm, 2.0 mm, and 2.54 mm. There is no enough space (37*1.27=46.99 mm) to install PINs. But the minimum pitch of conductive rubber strip or zebra is 0.3 mm or 0.4 mm, therefore there is enough space (37*0.4=14.8 mm).

You may notice that LED backlight and PCB are the same sizes. But how can we fasten the LED backlight and PCB together? We need a plastic shell with a hole to hold all these pieces tight. Besides, there are 3 hooks in the LED backlight to hold the LCD screen. The disadvantage of this design is that it is expensive because it needs two special molds: one round LCD screen with a small semi-circle missing and a dedicated light guide plate which is to make LED backlight. And I don’t think it is very stable because all the parts are only held by the plastic shell (or cover).

Second, we extend it 2.0 mm (1.5 mm at least), see the green line in the picture above, and we get a bigger octagon which is the area of the LCD screen.

We can see that LED backlight (83.0*83.0 mm) is a little bigger than LCD screen (81.0*81.0 mm) and view area of them is exactly the same. Although we can’t fasten the LED backlight and the LCD screen together because there is no hook or screw, but there is enough space in the PCB to install the screws which can hold onto other objects. This plan C needs a plastic shell or cover as big as plan B to hold all of them together. Here I figure out some pros and cons of these plans. pricespacetechnology requirementsstylishstable

The driver used in this LCD is GC9A01, with a resolution of 240RGB×240 dots and 129600 bytes of GRAM inside. This LCD supports 12-bits/16-bits/18-bits data bus by MCU interface, which are RGB444, RGB565, RGB666.

For most LCD controllers, the communication method of the controller can be configured, they are usually using 8080 parallel interface, 3-line SPI, 4-line SPI, and other communication methods. This LCD uses a 4-line SPI interface for reducing GPIO and fast speed.LCD

If you are wondering which point is the first pixel of the screen (because the screen is round), you can understand it as a square screen with an inscribed circle drawn in it, and it only displays the content in this inscribed circle. The pixels in other locations are simply discarded (just like most round smartwatches on the market)

If a number has more digits to the left of the decimal point than there are placeholders in the format code, the extra digits are displayed in the cell. However, if a number has more digits to the right of the decimal point than there are placeholders in the format code, the number is rounded off to the same number of decimal places as there are placeholders. If the format code contains only number signs (#) to the left of the decimal point, numbers with a value of less than 1 begin with the decimal point, not with a zero followed by a decimal point.

To hide zeros or to hide all values in cells, create a custom format by using the codes below. The hidden values appear only in the formula bar. The values are not printed when you print your sheet. To display the hidden values again, change the format to the General number format or to an appropriate date or time format.

SwiftUI gives us five built-in shapes that are commonly used: rectangle, rounded rectangle, circle, ellipse, and capsule. The last three in particular are subtly different in how they behave based on what sizes you provide, but we can demonstrate all the options with a single example:

RoundedRectangle does the same, except now you can round the corners by a certain amount. Its second parameter, style, determines whether you want classic rounded corners (.circular) or Apple’s slightly smoother alternative (.continuous).

Capsule draws a box where one edge axis is rounded fully, depending on whether the height or width is largest. Our shape is 100x50, so it will have rounded left and right edges while being straight on the top and bottom edges.

This sample shows how to define custom properties on clusters that are defined using data-driven style expresison calculation. These calculations aggregate values across all points contained within the cluster.

This sample shows how to customize the rendering of the drawing shapes in the drawing manager by accessing the rendering layers using the drawingManager.getLayers() function.

This sample shows how to create a heat map where the radius of each data point covers the same physical area on the ground and creates a more consistent user experience when zooming the map.

This sample shows how to limit the map such that it renders only a single copy of the map and restricts panning and zooming to minimize any whitespace appearing around the map.

This sample shows how to use the Services module for Azure Maps to perform a fuzzy search for points of interests, address, and places. Providing user location information allows the search service choose results that are more local to the user.

This sample shows how to use the Services module for Azure Maps to search for locations that have boundaries and display them on the map. Azure Maps provides boundary data for administrative areas such as states, countries, cities, postal codes, and other boundaries such as industrial areas.

If you"re wondering what to put on your Business Card, simply pick one of our Business Card design templates and customize the placeholder copy with your information. You can add your own logo and images, and even a catchy tagline!

Never leave home without your favorite photo, design, or inspirational message attached to your keys with this custom circle keychain. Designed to withstand daily wear and tear, this keychain displays designs, text, and photos in vibrant clarity and brilliant colors.

Designer Tip: To ensure the highest quality print, please note that this product’s customizable design area measures 2" x 2". For best results please add 1/16" bleed.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey