negative lcd panel manufacturer

A wide variety of negative lcd panel options are available to you, You can also choose from original manufacturer, odm negative lcd panel,As well as from tft, standard, and tn.

LCD (Liquid Crystal Displays) have two options or display modes.Positive mode (dark characters on a light colored background) and negative mode (lighter colored characters on a darker background).

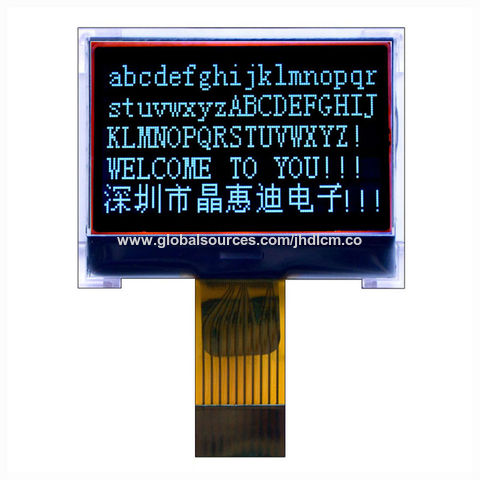

Please see Fig.1: Yellow green STN (Super Twisted Nematic) display, the background of yellow green is lighter than dark blue characters. It is a positive mode. Fig. 2 is a blue STN display, its background of blue is darker than the white characters.It is negative mode.

Negative mode displays need backlit in order to be seen. They normally use transmissive polarizers. They have better contrast and wider viewing angles in the indoor dim environment. The readability is much better than positive displays.

Of course, we can always use LED backlight in the LCD module with fewer LED chips and turn off LED backlight when not use to save power. When can also add transflective polarizer to some negative LCDs to make it sunlight readable, but the contrast will be compromised.

Positive and negative mode concept is not only limited to monochrome LCD displays (LCD panels, character LCDs, graphic LCDs etc.), it also uses for color displays, or even other display technologies. We will categorize the displays as below,

Character LCD modules (Alphanumeric LCD display modules) with character sets: 8×1 LCD display, 8×2 LCD display, 16×1 LCD display, 16×2 LCD display, 16×4 LCD display, 20×2 LCD display, 20×4 LCD display, 24×2 LCD display, 40×2 LCD display, 40×4 LCD display. COB (Chip on Board) bonded, 4 or 8 bits parallel, SPI, I2C interface

Graphic LCD modules with dot matrix sets 122×32, graphic LCD display, 128×64 graphic LCD display, 192×48 graphic LCD display,192×64 graphic LCD display,240×64 graphic LCD display,240×128 graphic LCD display,240×160 graphic LCD display with different color LED backlights, with COB and COG (Chip on Glass) assembling technologies

Full Color TN and IPS displays with panel sizes: 1.3”IPS display, 1.44” TN display, 1.5” IPS display, 1.77”TN and IPS displays, 2.0” TN and IPS displays, 2.2” IPS display, 2.35” IPS display, 2.4” TN and IPS displays, 2.8” TN and IPS displays, 3.5” TN and IPS displays, 4.3” TN display, 5.0” TN and IPS display, 7.0” TN and IPS display, 10.1” IPS display with medium and high brightness (sunlight readable), with parallel, SPI, RGB, LVDS, MIPI interfaces.

NHD-C12864WO-B1TTI#-M | Monochrome Graphic COG | 128x64 Pixels | White Pixels on Black Background | White Backlight | FSTN (-) Negative Display | Mounting Holes | Non-Stocked

Newhaven 128x64 graphic Chip-On-Glass (COG) Liquid Crystal Display shows white pixels on black background. This transmissive LCD Display requires a backlight for visibility and offers a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-C12864WO-B1TTI#-M display includes mounting holes. It has an optimal view of 6:00, operates at 3.3V supply voltage and is RoHS compliant.

Newhaven 16x2 character Liquid Crystal Display shows characters with bright pixels on a black background. The RGB display includes three backlight colors built into each display, which enables you to choose from a red, green or a blue backlight color. You can also mix the intensities of those colors to create new custom colors. This transmissive LCD Display requires a backlight for visibility while offering a wide operating temperature range from -20 to 70 degrees Celsius. This NHD-0216K3Z-NS(RGB)-FBW-V3 display has an optimal view of 6:00, operates at 5V supply voltage, and is RoHS compliant.

Densitron"s NEW Line of Negative Mode LCDs are designed specifically to offer a brilliant display into the tight form factor of 1RU ( 1U ) rack size applications. Where OLED was once considered the only technology that provided the stunning new look you were after, these ultra bright 1RU LCD modules offer an option to mid market customers who need long product availability.

These LCDs utilize premium materials and excellent cell gap control to accommodate the high graphic content of a 240 x 64 display packed into a module that is only 34mm tall. The stunning photos demonstrate virtually no cross talk common to some standard displays. Most standard FSTN displays appear washed out due to their dark gray background and dim backlight. The Densitron LM5428 series offer stunning contrast due to their combination of dark black (or dark blue) background and ultra bright LED design.

Liquid crystal display (LCD) panels are the most widespread type of display panels in use today. They are found in a plethora of electronic devices including wristwatches, smartphones, handheld gaming consoles, laptop computers, televisions, gasoline pumps, etc.

A liquid crystal is a substance which is liquid in form, but with properties akin to solid crystals. Liquid crystal substances were purportedly discovered as early as 1888, but their commercialization in making display panels did not occur until the 1970s, when the digital wristwatch was introduced.

Since their commercialization, some electronic devices with LCD panels have had a profound negative impact on certain traditional industries. For example, the Swiss mechanical wristwatch industry suffered severe losses in the 1970s as a result of the commercialization of low-priced digital wristwatches. Moreover, the reduction in price of LCD monitors and TVs in the early to mid-2000s caused the end the seven decade long production of cathode ray tube (CRT) TVs in the U.S.

However, will LCD panel technology survive with the slow but gradually expanding application of light emitting diode (LED) panels? LED panels are now incorporated in various electronic devices such as smart watches, smartphones, TVs, etc.

These statistics indicate that approximately 2920 U.S. patent applications were filed in 2014 for technological improvements in the field of LCD devices (e.g., computer monitors, smartphone displays, TVs, etc.), followed by approximately 3040 in 2015, approximately 2400 in 2016 and approximately 2240 in 2017. On the other hand, about 2920 U.S. patents were filed in 2014 for technological improvements in the field of LED devices, followed by about 2900 in 2015, about 2750 in 2016 and about 2660 in 2017. Since patent applications are generally maintained secret until 18 months after filing of a patent application, the filing data for 2018 and 2019 is not yet available.

These statistics indicate that patent applications for both the LED and LCD devices are being filed in large numbers. However, the number of annual filings for LCD panels is somewhat lower than that of LED panels for 2016 and 2017.

Statistics gathered from the U.S. Patent and Trademark Office concerning the number of patents granted in both technological fields in recent years indicate that approximately 2600 U.S. patents were issued in 2015 for improvements in the field of LCD devices, followed by approximately 2400 in 2016, approximately 2520 in 2017 and approximately 2320 in 2018. On the other hand, about 2400 U.S. patents were issued in 2015 for improvements in the field of LED devices, about 2410 in 2016, about 2560 in 2017 and about 2440 in 2018.

The statistics provided above illustrate that the number of applications and patents granted for LCD displays in recent years is somewhat lower than of LED displays, but this fact alone may not be enough to conclude that LCD displays are headed into obsolescence.

In order to form a rational prediction as to which type of display panel will ultimately prevail in the future, additional factors must be considered. These factors include the complication involved with the manufacturing process and the manufacturing costs associated with each type of display panel, how thin can each type of display panel be manufactured, and any unique features or attributes associated with each type of display panel.

LCD panels have a backlight assembly that directs white light into a liquid crystal layer. The liquid crystal layer acts like a shutter in order to allow only a desired quantity of light to pass through at each pixel of the panel. Having passed through the liquid crystal layer, the light then passes through a color filter in order to become colored light. The colored light forms the image on the panel.

Other structural arrangements of LCD panels exist, but the above example is intended to illustrate the three main structural components of an LCD panel.

An LED panel, on the other hand, is composed of a large number of individual LEDs arranged in rows and columns, similar to the arrangement of the pixels in an LCD panel. However, this is where the similarities between the two types of display panels end.

Each individual LED in the panel is configured to emit light of a predetermined color toward the user. A large number of LEDs which emit light of different colors form a desired image on the screen. However, in order to form the image, and to change it as needed (e.g., to view a video), the brightness of the individual LEDs must be varied up and down. This can be accomplished by changing the voltage applied to each individual LED in the panel.

As can be gleaned, because the LEDs emit colored light, LED panels do not need a separate light source (e.g., a backlight) for generating light, and they do not need a separate color filter placed over the light source in order to generate colored light. In addition, because the LEDs themselves can produce the desired brightness of light, LED panels do not need an additional shutter mechanism. Thus, LED panels have a simpler structure than LCD displays.

In addition, LED displays can be curved to a much smaller radius than LCD panels, and can be manufactured to be foldable or bendable. For example, the SAMSUNG Galaxy Fold is a smartphone with a foldable LED display panel. LCD panels cannot be made to bend (beyond a minimal degree) or fold.

While the image quality is very good on both types of displays, LED panels have a larger contrast ratio due to the deeper black color that they can render. This is because the LED pixels which are responsible for generating black are simply turned off in order to avoid emitting any light at all. This feature is unique to LED panels.

LCD panels generate black by attempting to block the transmission of light emitted from the backlight. However, the shutter mechanism of LCD panels is not perfect and allows a small quantity of light to escape (or leak) toward the user. The leakage of light causes the black areas of an image to appear dark gray on the screen.

In addition, LED panels can be made thinner than LCD panels since they omit the backlight assembly, the liquid crystal layer, and the color filer layer.

In conclusion, with all the pros of LED panels over LCDs, it seems that the answer to the question posed above hinges on manufacturing/retail costs. LCD panels still exist because they can produce good quality images at a low cost. If LED panels can be produced and sold at a cost comparative to that of LCD panels, the LCD panel technology may well become history.

_2.jpg)

For product design engineers and manufacturers, a custom display and touch solution is the best approach to meet their unique application needs. Turning to us to be your monochrome LCD manufacturer means you’ll gain the experience and expertise of our in-house engineering team. Our talented engineers can develop customized solutions using a wide range of LCD technologies:Custom TN LCD displays

Negative LCD Display one type of LCD display model. Negative LCD Display must need a backlight to make the words/patterns clear to see. We make custom LCD and customized backlight to meet some products style.

LCD Viewing Modes The type of image the display will create is a cosmetic issue the engineering and marketing department work out. This is the easiest choice since there are only two basic selections, and we will go over each of them and what they mean:

POSITIVE IMAGEA positive image on an LCD display is when the pixel is "OFF" it is transparent, when a pixel in "ON" it is opaque. On almost all displays the image is smaller than the background, so this mode of operation is favored in an application where ambient light is high and it will help with the contrast of the display, especially for a display utilizing a Reflective rear polarizer. Here are several typical Operational Mode & Viewing Mode combinations and the resulting images (assuming no backlighting which can color the background):

NEGATIVE IMAGEA negative image on an LCD display is when the pixel is "OFF" it is opaque, when a pixel in "ON" it is transparent. Since the image area is typically smaller than the background, the portion of the display that could reflect light and give the characters definition in this mode is minimized. Therefore, this mode is typically only used when there is a backlight and the ambient lighting conditions are medium to dim. Using a backlight, the transparent segments of the display will "glow" because the backlight will be viewable only when the pixels are turned on. A high ambient light condition could wash out the backlight. Here are several typical Operational Mode & Viewing Mode combinations and the resulting images (assuming a backlight with the specified coloration listed):

Each LCD has 2 polarizers, the front and rear polarizers, applied accordingly across the front of the display viewing surface and across the rear of the display to determine how the infuse light into the display. The front polarizer is always Transmissive and not selectable by the user, however the rear polarizer has 3 choices and two grades for each choice. The rear polarizer selection is as follows:

REFLECTIVE POLARIZERReflective displays have an opaque rear polarizer that includes a diffuse reflector, such as brushed aluminum. This layer reflects polarized ambient light that has entered the front of the display back trough the LCD cell. Reflective displays require ambient light to be seen. They exhibit high brightness, excellent contrast, and wide viewing angles. They are particularly suitable for use in battery operated equipment where an adequate level of light is always available. Reflective LCD"s cannot be backlit, however they can be front lighted in some applications.

Transmissive displays have a clear polarizer on the front and the back. The display therefore depends on light coming through from the back of the display toward the observer in order to be seen. Most, but not all transmissive displays are negative image, and we sometimes add colored filters to different areas of the display to highlight different annunciators. Another example of a transmissive polarizer display would be a transparent window where you could see the segments superimposed over your line of vision through the display window (this assumes a sufficient ambient light source exists on either side of the window).

Transflective displays have a rear polarizer which includes a translucent material which reflects part of the ambient light, and also transmits backlighting. As the name implies, it is a compromise between the transmissive and reflective viewing mode. Used in reflection, it is not as bright and has lower contrast than the reflective type LCD, but it can be backlit for use in low light conditions. This polarizer is the best selection for a display that can be used in all lighting conditions with a backlight.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey