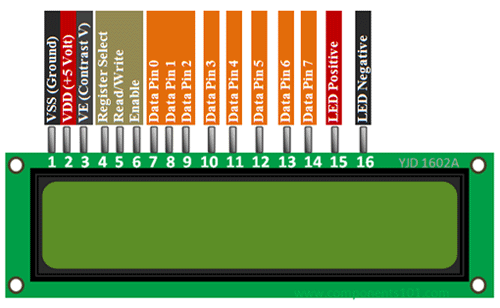

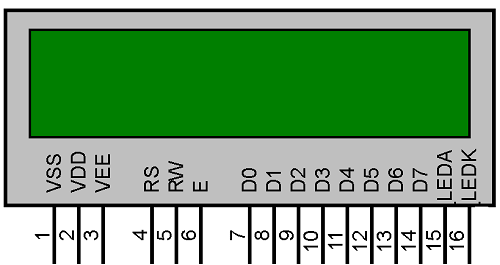

1602 16x2 lcd module pin brands

The LCDduino board enables users to create many applications/projects that require a 16×2 LCD display and Arduino. The board has the exact size of 16×2 LCD and can be installed on the backside of the LCD. This is a low-cost solution that has onboard Arduino + LCD so no extra Arduino Nano or Arduino board is required. The Arduino compatible hardware includes onboard programming and boot-loader connectors, Atmega328 microcontroller, and 16×2 LCD interface. Each Arduino I/O Pin including the VCC and GND is exposed to the connectors for easy connection with sensors and other devices. The board enables the easy interface of many devices and sensors. The operating power supply is 7 to 15V DC.

The character type liquid crystal display module is a dot matrix liquid crystal display module specifically for displaying letters, numbers, symbols, and the like. It is divided into 4-bit and 8-bit data transmission methods. Provides a 5×7 dot matrix + cursor display mode. A display data buffer generator CGRAM is provided, and CGRAM can be used to store font data of up to eight 5×8 dot matrix graphic characters defined by itself. Provides a wealth of command settings: clear display; cursor back to origin; display on / off; cursor on / off; display character flicker; cursor shift; display shift. An internal power-on automatic reset circuit is provided. When the external power supply voltage exceeds +4.5V, the module is automatically initialized and the module is set to the default display working state.

Do you want your Arduino projects to display status messages or sensor readings? Then these LCD displays can be a perfect fit. They are extremely common and fast way to add a readable interface to your project.

This tutorial will help you get up and running with not only 16×2 Character LCD, but any Character LCD (16×4, 16×1, 20×4 etc.) that is based on Hitachi’s LCD Controller Chip – HD44780.

True to their name, these LCDs are ideal for displaying only text/characters. A 16×2 character LCD, for example, has an LED backlight and can display 32 ASCII characters in two rows of 16 characters each.

The good news is that all of these displays are ‘swappable’, which means if you build your project with one you can just unplug it and use another size/color LCD of your choice. Your code will have to change a bit but at least the wiring remains the same!

Vo (LCD Contrast) controls the contrast and brightness of the LCD. Using a simple voltage divider with a potentiometer, we can make fine adjustments to the contrast.

RS (Register Select) pin is set to LOW when sending commands to the LCD (such as setting the cursor to a specific location, clearing the display, etc.) and HIGH when sending data to the LCD. Basically this pin is used to separate the command from the data.

R/W (Read/Write) pin allows you to read data from the LCD or write data to the LCD. Since we are only using this LCD as an output device, we are going to set this pin LOW. This forces it into WRITE mode.

E (Enable) pin is used to enable the display. When this pin is set to LOW, the LCD does not care what is happening on the R/W, RS, and data bus lines. When this pin is set to HIGH, the LCD processes the incoming data.

D0-D7 (Data Bus) pins carry the 8 bit data we send to the display. For example, if we want to see an uppercase ‘A’ character on the display, we set these pins to 0100 0001 (as per the ASCII table).

Now we will power the LCD. The LCD has two separate power connections; One for the LCD (pin 1 and pin 2) and the other for the LCD backlight (pin 15 and pin 16). Connect pins 1 and 16 of the LCD to GND and 2 and 15 to 5V.

Most LCDs have a built-in series resistor for the LED backlight. You’ll find this near pin 15 on the back of the LCD. If your LCD does not include such a resistor or you are not sure if your LCD has one, you will need to add one between 5V and pin 15. It is safe to use a 220 ohm resistor, although a value this high may make the backlight a bit dim. For better results you can check the datasheet for maximum backlight current and select a suitable resistor value.

Next we will make the connection for pin 3 on the LCD which controls the contrast and brightness of the display. To adjust the contrast we will connect a 10K potentiometer between 5V and GND and connect the potentiometer’s center pin (wiper) to pin 3 on the LCD.

That’s it. Now turn on the Arduino. You will see the backlight lit up. Now as you turn the knob on the potentiometer, you will start to see the first row of rectangles. If that happens, Congratulations! Your LCD is working fine.

Let’s finish connecting the LCD to the Arduino. We have already made the connections to power the LCD, now all we have to do is make the necessary connections for communication.

We know that there are 8 data pins that carry data to the display. However, HD44780 based LCDs are designed in such a way that we can communicate with the LCD using only 4 data pins (4-bit mode) instead of 8 (8-bit mode). This saves us 4 pins!

4-bit mode is often used to save I/O pins. However, 8-bit mode is best used when speed is required in an application and there are at least 10 I/O pins available.

The sketch begins by including the LiquidCrystal library. The Arduino community has a library called LiquidCrystal which makes programming of LCD modules less difficult. You can find more information about the library on Arduino’s official website.

First we create a LiquidCrystal object. This object uses 6 parameters and specifies which Arduino pins are connected to the LCD’s RS, EN, and four data pins.

In the ‘setup’ we call two functions. The first function is begin(). It is used to specify the dimensions (number of columns and rows) of the display. If you are using a 16×2 character LCD, pass the 16 and 2; If you’re using a 20×4 LCD, pass 20 and 4. You got the point!

After that we set the cursor position to the second row by calling the function setCursor(). The cursor position specifies the location where you want the new text to be displayed on the LCD. The upper left corner is assumed to be col=0, row=0.

There are some useful functions you can use with LiquidCrystal objects. Some of them are listed below:lcd.home() function is used to position the cursor in the upper-left of the LCD without clearing the display.

lcd.scrollDisplayRight() function scrolls the contents of the display one space to the right. If you want the text to scroll continuously, you have to use this function inside a for loop.

lcd.scrollDisplayLeft() function scrolls the contents of the display one space to the left. Similar to above function, use this inside a for loop for continuous scrolling.

If you find the characters on the display dull and boring, you can create your own custom characters (glyphs) and symbols for your LCD. They are extremely useful when you want to display a character that is not part of the standard ASCII character set.

CGROM is used to store all permanent fonts that are displayed using their ASCII codes. For example, if we send 0x41 to the LCD, the letter ‘A’ will be printed on the display.

CGRAM is another memory used to store user defined characters. This RAM is limited to 64 bytes. For a 5×8 pixel based LCD, only 8 user-defined characters can be stored in CGRAM. And for 5×10 pixel based LCD only 4 user-defined characters can be stored.

Typically, users have the ability to adjust the contrast of an LCD module. This application note describes characteristics and methods withregards to contrast adjustment, as well as design guidelines for proper operation. An example application circuit is shown at the end using a 16x4 character LCD.

The ratio of light to dark areas on an LCD is defined as the contrast ratio. This is one consideration for designers when adjusting the LCD bias voltage. This voltage is represented by: Vee, Ve or Vo. Focus LCDs will reference bias voltage as Vo throughout this document.

Vo is used to power the circuits that drive the LCD. This voltage sets the contrast level of the LCD. Any changes in this voltage will cause a visible change in the contrast, it’s important that it is regulated with less than 100mV ripple.

The circuit in Figure 3 does the same job of varying bias but digitally using a microcontroller through pin 2(ADJ). A CTRL (enable) pin is also provided for turning on or off via the microcontroller. This shutdown signal can also be used to properly sequence the power to the display during power-up and power-down sequences.

Note that pin 2 (SHDN) serves as an enable pin to turn on or off the bias voltage. This is important for power sequencing which will be discussed shortly.

It is critical that the LCD bias is applied at the appropriate time with reference to another signal (power sequence). The power sequence is the sequence in which the power is applied and shut down, and includes specifications of the time intervals between steps in the sequence.

For LCD modules, the simple rule is Vo (Vee or Vi) must never be present without VDD also being present. Otherwise, the display may be damaged even if it is only for a short period.

Buyers and others who are developing systems that incorporate FocusLCDs products (collectively, “Designers”) understand and agree that Designers remain responsible for using their independent analysis, evaluation and judgment in designing their applications and that Designers have full and exclusive responsibility to assure the safety of Designers" applications and compliance of their applications (and of all FocusLCDs products used in or for Designers’ applications) with all applicable regulations, laws and other applicable requirements.

Designer agrees that prior to using or distributing any applications that include FocusLCDs products, Designer will thoroughly test such applications and the functionality of such FocusLCDs products as used in such applications.

The easiest way would be to stick a transistor inline with the power lead of the lcd and turn it off just before the cpu goes into the low power state.

This product worked great. I wrote a tutorial about manually writing data to the display using dips switches and push buttons. http://volatileinterface.com/2015/05/30/using-a-hd44780-lcd-display-in-4-bit-mode/

Completely useless, I have no idea what happened but when I wire it up according to the tutorial on arduinos site for the Hello World! LCD program, nothing but the backlight comes on. Also the pins are flipped from where they are in the schematic. Total cluster fuck of a product.

So apparently the product works fine, and I apologize to all those at sparkfun. I should be on the arduino forums tell them that the tutorial is a cluster F**k and not this item. for those who had the same problem, you have to connect pin 15 Vin and pin 16 to GND, everything on the tutorial is correct.

I just realized I forgot the bridge connections over the cnter of the breadboard to actually connect the data lines to the LCD. It works now I think I need to adjust the contrast or something. The text on the display is more visible when looking at the display from an angle.

I just bought this and thought it had the HD44780 chipset but now I started looking at the datasheet for the pin interface descriptions and I realize that it has the KS006U chipset? Is the datasheet wrong or is the sparkfun description wrong? Or maybe they are basically the same chipset? I"m confused right now. Do I need to buy a different LCD?

HD44780 is more a standard that a chipset at this point. there are tons of different chipsets that use the same protocols. like how people say "allen wrench" instend of saying hex key. HD44780 is the LCD equivilent of X86 instruction set. the cool think is you can lean how to use the 16x2, and then use the same code on everything from 8x1 to 40x4 displays.

You can simulate data on each pin of the HD44780 compatible LCD and see how it works, or if you are more advanced you can write directly your own scripts in the web browser to control the LCD, same as you would use them in the MCU code

Is there a flat cable assembly available for these? I"m OK using the 0.1" headers, but the electronics I need to hook up requires a cable interconnect. And I"d like it so that I can replace the LCD without desoldering it.

This is a very late response, but anybody in this situation can simply connect the LCD in series with a MOSFET. YOu can then switch the LCD on and off from a microcontroller. Remember to leave all the microcontroller outputs floating because power can still flow into the LCD if you keep these in certain states.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey