tft display curved free sample

An excellent new compatible library is available which can render TrueType fonts on a TFT screen (or into a sprite). This has been developed by takkaO and is available here. I have been reluctant to support yet another font format but this is an amazing library which is very easy to use. It provides access to compact font files, with fully scaleable anti-aliased glyphs. Left, middle and right justified text can also be printed to the screen. I have added TFT_eSPI specific examples to the OpenFontRender library and tested on RP2040 and ESP32 processors, however the ESP8266 does not have sufficient RAM. Here is a demo screen where a single 12kbyte font file binary was used to render fully anti-aliased glyphs of gradually increasing size on a 320x480 TFT screen:

The TFT configuration (user setup) can now be included inside an Arduino IDE sketch providing the instructions in the example Generic->Sketch_with_tft_setup are followed. See ReadMe tab in that sketch for the instructions. If the setup is not in the sketch then the library settings will be used. This means that "per project" configurations are possible without modifying the library setup files. Please note that ALL the other examples in the library will use the library settings unless they are adapted and the "tft_setup.h" header file included. Note: there are issues with this approach, #2007 proposes an alternative method.

Support has been added in v2.4.70 for the RP2040 with 16 bit parallel displays. This has been tested and the screen update performance is very good (4ms to clear 320 x 480 screen with HC8357C). The use of the RP2040 PIO makes it easy to change the write cycle timing for different displays. DMA with 16 bit transfers is also supported.

Smooth fonts can now be rendered direct to the TFT with very little flicker for quickly changing values. This is achieved by a line-by-line and block-by-block update of the glyph area without drawing pixels twice. This is a "breaking" change for some sketches because a new true/false parameter is needed to render the background. The default is false if the parameter is missing, Examples:

New anti-aliased graphics functions to draw lines, wedge shaped lines, circles and rounded rectangles. Examples are included. Examples have also been added to display PNG compressed images (note: requires ~40kbytes RAM).

Frank Boesing has created an extension library for TFT_eSPI that allows a large range of ready-built fonts to be used. Frank"s library (adapted to permit rendering in sprites as well as TFT) can be downloaded here. More than 3300 additional Fonts are available here. The TFT_eSPI_ext library contains examples that demonstrate the use of the fonts.

Users of PowerPoint experienced with running macros may be interested in the pptm sketch generator here, this converts graphics and tables drawn in PowerPoint slides into an Arduino sketch that renders the graphics on a 480x320 TFT. This is based on VB macros created by Kris Kasprzak here.

The RP2040 8 bit parallel interface uses the PIO. The PIO now manages the "setWindow" and "block fill" actions, releasing the processor for other tasks when areas of the screen are being filled with a colour. The PIO can optionally be used for SPI interface displays if #define RP2040_PIO_SPI is put in the setup file. Touch screens and pixel read operations are not supported when the PIO interface is used.

DMA can now be used with the Raspberry Pi Pico (RP2040) when used with both 8 bit parallel and 16 bit colour SPI displays. See "Bouncy_Circles" sketch.

The library now supports the Raspberry Pi Pico with both the official Arduino board package and the one provided by Earle Philhower. The setup file "Setup60_RP2040_ILI9341.h" has been used for tests with an ILI9341 display. At the moment only SPI interface displays have been tested. SPI port 0 is the default but SPI port 1 can be specifed in the setup file if those SPI pins are used.

The library now provides a "viewport" capability. See "Viewport_Demo" and "Viewport_graphicstest" examples. When a viewport is defined graphics will only appear within that window. The coordinate datum by default moves to the top left corner of the viewport, but can optionally remain at top left corner of TFT. The GUIslice library will make use of this feature to speed up the rendering of GUI objects (see #769).

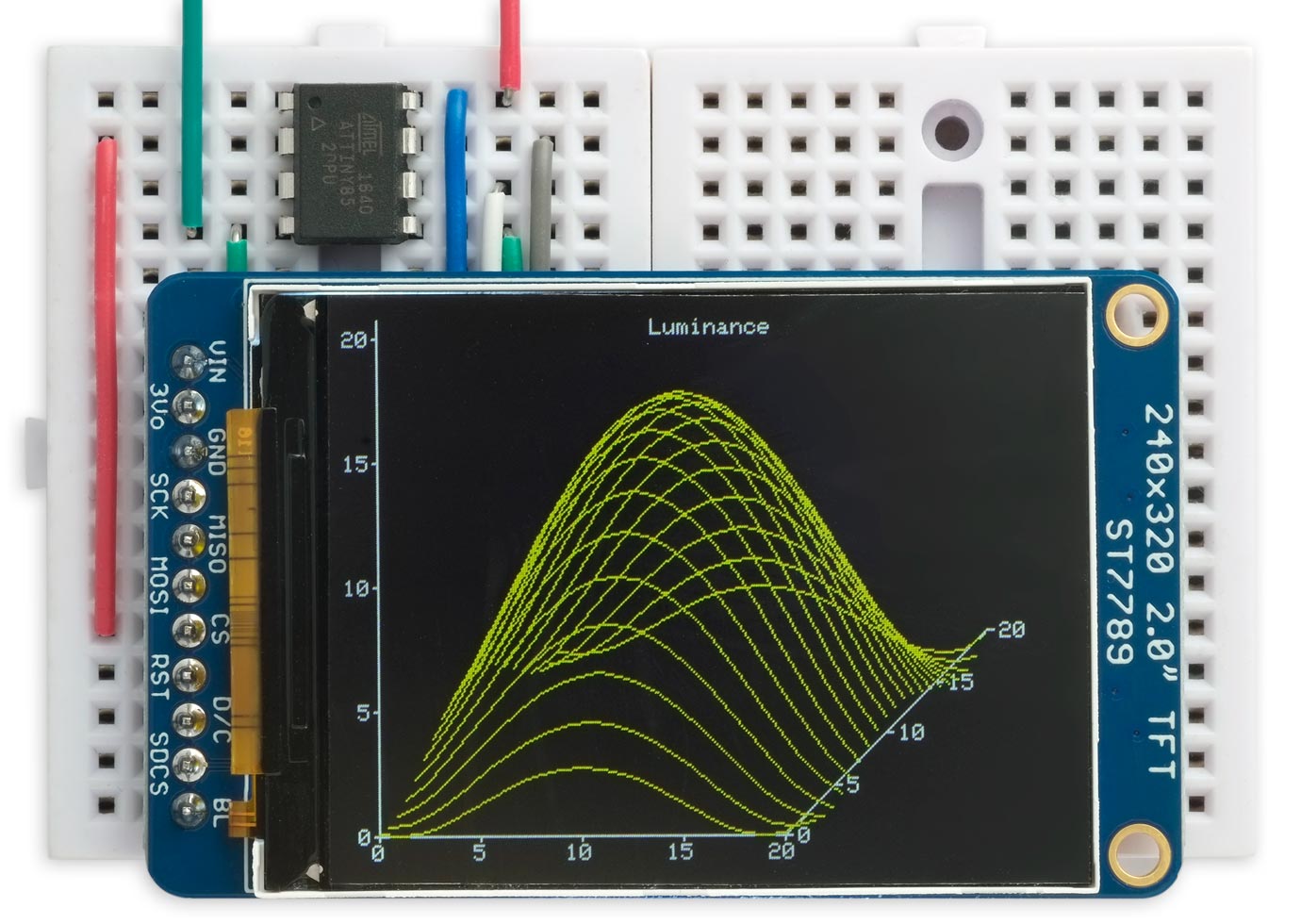

An Arduino IDE compatible graphics and fonts library for 32 bit processors. The library is targeted at 32 bit processors, it has been performance optimised for STM32, ESP8266 and ESP32 types. The library can be loaded using the Arduino IDE"s Library Manager. Direct Memory Access (DMA) can be used with the ESP32, RP2040 and STM32 processors with SPI interface displays to improve rendering performance. DMA with a parallel interface is only supported with the RP2040.

For other processors the generic only SPI interface displays are supported and slower non-optimised standard Arduino SPI functions are used by the library.

"Four wire" SPI and 8 bit parallel interfaces are supported. Due to lack of GPIO pins the 8 bit parallel interface is NOT supported on the ESP8266. 8 bit parallel interface TFTs (e.g. UNO format mcufriend shields) can used with the STM32 Nucleo 64/144 range or the UNO format ESP32 (see below for ESP32).

The library supports some TFT displays designed for the Raspberry Pi (RPi) that are based on a ILI9486 or ST7796 driver chip with a 480 x 320 pixel screen. The ILI9486 RPi display must be of the Waveshare design and use a 16 bit serial interface based on the 74HC04, 74HC4040 and 2 x 74HC4094 logic chips. Note that due to design variations between these displays not all RPi displays will work with this library, so purchasing a RPi display of these types solely for use with this library is not recommended.

A "good" RPi display is the MHS-4.0 inch Display-B type ST7796 which provides good performance. This has a dedicated controller and can be clocked at up to 80MHz with the ESP32 (55MHz with STM32 and 40MHz with ESP8266). The MHS-3.5 inch RPi ILI9486 based display is also supported.

Some displays permit the internal TFT screen RAM to be read, a few of the examples use this feature. The TFT_Screen_Capture example allows full screens to be captured and sent to a PC, this is handy to create program documentation.

The library supports Waveshare 2 and 3 colour ePaper displays using full frame buffers. This addition is relatively immature and thus only one example has been provided.

The library includes a "Sprite" class, this enables flicker free updates of complex graphics. Direct writes to the TFT with graphics functions are still available, so existing sketches do not need to be changed.

The "Animated_dial" example shows how dials can be created using a rotated Sprite for the needle. To run this example the TFT interface must support reading from the screen RAM (not all do). The dial rim and scale is a jpeg image, created using a paint program.

The XPT2046 touch screen controller is supported for SPI based displays only. The SPI bus for the touch controller is shared with the TFT and only an additional chip select line is needed. This support will eventually be deprecated when a suitable touch screen library is available.

The library supports SPI overlap on the ESP8266 so the TFT screen can share MOSI, MISO and SCLK pins with the program FLASH, this frees up GPIO pins for other uses. Only one SPI device can be connected to the FLASH pins and the chips select for the TFT must be on pin D3 (GPIO0).

Configuration of the library font selections, pins used to interface with the TFT and other features is made by editing the User_Setup.h file in the library folder, or by selecting your own configuration in the "User_Setup_Selet,h" file. Fonts and features can easily be enabled/disabled by commenting out lines.

It would be possible to compress the vlw font files but the rendering performance to a TFT is still good when storing the font file(s) in SPIFFS, LittleFS or FLASH arrays.

Anti-aliased fonts can also be drawn over a gradient background with a callback to fetch the background colour of each pixel. This pixel colour can be set by the gradient algorithm or by reading back the TFT screen memory (if reading the display is supported).

The common 8 bit "Mcufriend" shields are supported for the STM Nucleo 64/144 boards and ESP32 UNO style board. The STM32 "Blue/Black Pill" boards can also be used with 8 bit parallel displays.

Unfortunately the typical UNO/mcufriend TFT display board maps LCD_RD, LCD_CS and LCD_RST signals to the ESP32 analogue pins 35, 34 and 36 which are input only. To solve this I linked in the 3 spare pins IO15, IO33 and IO32 by adding wires to the bottom of the board as follows:

If the display board is fitted with a resistance based touch screen then this can be used by performing the modifications described here and the fork of the Adafruit library:

If you load a new copy of TFT_eSPI then it will overwrite your setups if they are kept within the TFT_eSPI folder. One way around this is to create a new folder in your Arduino library folder called "TFT_eSPI_Setups". You then place your custom setup.h files in there. After an upgrade simply edit the User_Setup_Select.h file to point to your custom setup file e.g.:

The library was intended to support only TFT displays but using a Sprite as a 1 bit per pixel screen buffer permits support for the Waveshare 2 and 3 colour SPI ePaper displays. This addition to the library is experimental and only one example is provided. Further examples will be added.

This new library is a standalone library that contains the TFT driver as well as the graphics functions and fonts that were in the GFX library. This library has significant performance improvements when used with an UNO (or ATmega328 based Arduino) and MEGA.

Examples are included with the library, including graphics test programs. The example sketch TFT_Rainbow_one shows different ways of using the font support functions. This library now supports the "print" library so the formatting features of the "print" library can be used, for example to print to the TFT in Hexadecimal, for example:

To use the F_AS_T performance option the ILI9341 based display must be connected to an MEGA as follows:MEGA +5V to display pin 1 (VCC) and pin 8 (LED) UNO 0V (GND) to display pin 2 (GND)

TFT_ILI9341 library updated on 1st July 2015 to version 12, this latest version is attached here to step 8:Minor bug when rendering letter "T" in font 4 without background fixed

Gaming monitors are specialized displays designed to have the lowest response times possible to stay ahead of the competition. PC monitors for office use may have slower response times but are more affordable and capable of performing general use tasks to improve productivity, viewing angles, and more.

Be sure to explore the interface options to ensure that you have the right connectivity for your unique needs. We have a huge variety of HDMI and DisplayPort options to help you make the most out of your hardware and make setting things up a breeze. You will also find USB C and VGA interface options here.

As the mainstream display mode of LCD, IPS is overwhelmingly used in many fields of flat displays. However, due to the stress sensitivity of glass, the stressed light leakage is a bottleneck for achieving perfect dark state performance. The conventional scheme of using a compensation polarizer outside the cell has no effect on this light leakage. Although many studies have been conducted to overcome this limitation, the proposed methods have limited effects. Our research team has proposed a novel light leakage compensation mechanism by introducing a positive A plate that is sandwiched between the glass and the LC layer, therefore the light leakage which is caused by the combined effect of the phase retardations from the stressed glasses and the LC layer can be eliminated. In addition to theoretically analyzing the compensation principles of the novel light leakage compensation mechanism, we also use the developed positive A material to prepare light leakage compensation demos. And then the electric-optical characteristics and light leakage compensation effects of the demos are evaluated. While maintaining excellent optical and electrical characteristics, this technology effectively solves the problem of stressed light leakage of glass-based IPS, improves the dark-state image quality, and breaks the application of IPS in products such as curve products.

After decades of development, IPS (In-Plane Switching) LCD (Liquid Crystal Display) occupies a dominant position in the display field. Due to its excellent display performance, IPS is widely used in all sizes of display products, such as mobile phones, tablet computers, notebook computers, monitors, and TVs

Due to the manufacturing process of CF/TFT glass and panel, and even the using process of IPS panel, it is difficult to completely avoid the stress birefringence of glass. Although some studies have proposed solutions, such as slimming of glass thickness

where σ is the stress from bending, E is Young’s modulus of glass (73,000 MPa for LCD display used glass), t is the thickness of the glass sheet and r is the radius to which the sheet is bent. In an ideal case, as the light passes through the bent glass, the in-plane retardation can be calculated by the stress-optic law shown in formula (

In this article, referring to the fundamental reason for light leakage, we have proposed a novel light leakage compensation mechanism, and a new LCD structure with an in-cell phase retarder as a solution. The basic idea of phase compensation is to introduce a positive A (+A) plate to compensate for the retardation of LC, make the stress birefringence of CF and TFT glass offset each other, and effectively eliminate light leakage. We have explained the compensation mechanisms, analyzed the electric-optical characteristics, and studied the effects of LL compensation. It is a very important point to note that, different from studies of compensation layers on improving the viewing angle

As mentioned above, our research focuses on stressed LL caused by mechanical deformation stress. When the panel is under force, due to the fixing effect of the sealant, the panel as a whole, it experiences tension on the TFT glass and compression on the CF glass as bending 1, under pure bending, these tensile and compressive stresses are equal in magnitude but opposite in direction. At the neutral axis where the transition between tensile and compressive zones occurs, the stress is zero.

And as shown in Fig. 2a, the angle between the optical axis of TFT glass and LC is θ, and the angle between the optical axis of CF glass and LC is θ + 90°. The residual stress of the glass or the uneven stress caused by the frame during the IPS manufacturing process will cause the glass to produce retardation. And the brightness of the LL is proportional to the square of phase retardation (δ). After the stressed retardation of glass is got, the LL can be confirmed by simulation software.

The stressed LL mechanism of normal IPS is illustrated by using the Poincaré sphere2a", PI (Point 1), P2 (Point 2), P3 (Point 3), and P4 (Point 4) respectively represent the polarization state of light after passing through the polarizer, the TFT glass, the LC layer, and the CF glass. Due to the effect of phase retardation of LC, a certain level of LL occurs. When the angle between the optical axis of LC and the glass with stress birefringence is 0° or 90°, the phase retardation of the LC is invalid, and there is no light leakage. But when the angle between the optical axis of LC and the optical axis of the glass with stress birefringence is not 0° or 90°, the vertically incident light becomes linearly polarized light after passing through the TFT polarizer, due to the effect of the LC phase retardation, the polarization state after passing through the TFT glass, the LC layer, and the CF glass is changed. When passing through the CF polarizer, it cannot be completely absorbed and LL occurs. As shown in Fig. 2a", the distance from P1 (Point 1) to P4 (Point 4) is proportional to LL brightness.

As shown in Fig. 2b, the first new LCD structure called compensation mode 1, introduces the +A plate, which is sandwiched between the glass and LC. More specifically, the optical axis of the +A plate is perpendicular to the initial optical axis of LC, and the phase retardation of the +A plate is 350 nm, which is equal to that of the LC.Fig. 2b" illustrates the compensation principle of compensation mode 1. When receives external stress, the light from the backlight unit traverses the TFT polarizer, the effective optical axis position on the Poincaré sphere is P1, when the light (P1) successively passes through the stressed TFT glass, its polarization state is rotated from P1 to P2. And when the light (P2) passes through LC, its polarization state is rotated from P2 to P3. Then, the light (P3) successively passes through the +A plate and the stressed CF glass, whose effective optical axis positions on the Poincaré sphere are P4 and P5, respectively. The intermediate polarization state (P2) in general, is an elliptical polarization state. Due to the role of the +A plate, the polarization state (P5) on the Poincaré sphere is very near to the polarization state (P1), so the light almost can be absorbed by the CF polarizer, and the elimination of LL is achieved.

The compensation structure of mode 2 is shown in Fig. 2c. The main difference between mode 1 and mode 2 is reflected in the role of the +A plate. For mode 1, +A plate realizes that the light follows the same path as LC, and returns back in the opposite direction to the same polarization state as the light before the incident LC. For mode 2, the +A plate realizes that the light continues along the same direction as the LC and moves forward with a certain optical path to the same polarization state as the light before the incident LC. So for mode 2, as shown in Fig. 2c", due to the role of +A plate, the polarization state (P5) on the Poincaré sphere is very near to the polarization state (P1) of the light passed through the TFT polarizer, so the light almost can be absorbed by CF polarizer and the LL compensation is realized.

When the thickness of the glass is not equal, such as the thickness of the CF glass is 0.3t and the thickness of the TFT glass is 0.4t, the panel as a whole still has the same compressive and tensile stresses on the neutral axis, but the neutral axis is not in the middle of the CF and TFT glass. When the neutral layer is located in the TFT glass, the CF glass has compressive stress. But the TFT glass has tensile and compressive stress, as the stress birefringence δ generated by each has different directions, the δcompressive of TFT can be offset by the δtensile of TFT, and finally, the δtensile of TFT will be equal to the δcompressive of CF glass. At this time, the situation is the same as when the thickness of TFT and CF glass is equal. So when the stresses of the CF and TFT glass are not completely equal, the proposed compensation mode can still effectively reduce light leakage.

According to the LL principle of the glass-based IPS and the compensation principle of the compensation mode, the +A film is required to be placed between the two glass substrates to compensate for the LC phase retardation. Integrating the display specification requirements of IPS products, a series of requirements are put forward for +A materials. Firstly, from the aspect of process manufacturing, it is required that the +A film should be prepared by IPS’s coating equipment, and the thickness of the +A film should be as thin as possible. Secondly, in terms of characteristics, the +A film is required to have excellent optical properties, such as transmittance and CR, and have good process stability and reliability. Therefore, the +A material is required to be a polymer material with LC characteristics. Although LC polymer materials have been extensively studied due to their good optical properties

In order to verify the LL elimination effect of compensation technology on curved samples, the samples of 13.3 inches with a curvature of 2800R/2500R/2000R/1500R/1000R are prepared. And the glass thickness of normal IPS and compensation samples are 0.5t/0.5t (TFT/CF glass). The L0 brightness at the center of the panel and at the four corners of the panel are tested respectively. And the LL compensation effect of different curvatures samples are compared and analyzed. The ratio of the brightness of the four corners to the center is used to represent the LL level. The larger the ratio, the greater the brightness of the four corners, and the worse the compensation effect of LL.

As shown in Fig. 11a, without compensation, the curved normal IPS has serious light leakage. When the curvatures of demos are 2800R/2500R/2000R/1500R/1000R, the ratios of the four corner brightness to the center brightness are 2.02/4.04/5.38/8.97/10.68, respectively. For the compensation demos, when the retardation of the +A plate is 200 nm and the curvatures are 2800R/2500R/2000R/1500R/1000R, the LL compensation effects are obvious, the ratios of the four corner brightness to the center brightness are 0.96/1.03/1.20/1.31/1.71, respectively. When the phase retardation of +A is between 113 and 240 nm, there is a certain effect of LL compensation, and when the retardation value of +A plate is between 180 and 220 nm, compensation technology can achieve a better LL compensation effect.

In addition, the photos of curved normal IPS and compensation mode 2 at 5000R, 2800R, 2000R are shown in Fig. 11b–g. It can be seen that compensation mode 2 can significantly reduce the brightness of LL compared with normal IPS, it still appears slightly purple and is different from that of the normal IPS. This is also caused by the dispersion characteristics of +A plate and LC materials, and can be optimized by adjusting the retardation and dispersion characteristics of +A plate and LC materials.

Consequently, according to the L0 brightness test results of the curved demos above, if the curved demos are prepared with 0.5t/0.5t (TFT/CF) glasses, the four corners of normal IPS demos have serious light leakage, but the compensation mode2 can achieve effective LL elimination. The thickness of 0.5t glass is a commonly used glass thickness in the IPS industry, which can achieve the greatest thickness reduction while meeting the strength of the glass in the manufacturing process. If the glass is thinned, although the stress birefringence of the glass can be reduced, it will also seriously reduce the strength of the glass and Introduce a series of inevitable problems, such as the lower yield rate and the increased cost caused by glass slimming.

In this paper, a compensation structure with excellent dark state image quality is proposed and experimentally analyzed. This technology can fundamentally improve the dark state LL even under deformation. By introducing a +A plate that is sandwiched between the glass and the homogeneous LC layer, the LL caused by the combined effect of the phase retardations from the stressed glasses and the LC layer can be eliminated. But the compensation layer for glass stressed LL must be placed between the upper and lower glass, inside the cell. The conventional scheme of using compensation polarizer outside the cell cannot achieve the compensation effect of the scheme proposed in this article. We have proposed two light leakage compensation mechanisms and structures, compensation mode 1 and mode 2. Considering the optical characteristics, especially the effect of CR of +A on the panel, we recommend the mode 2 solution. For mode 1, after the CR of +A material is improved, it is also a good light leakage improvement solution. This compensation technology is applicable for IPS modes. In addition to theoretical analysis of compensation principles, we have also developed +A materials that can meet the preparation process of IPS and prepared effective compensation demos. It is proved that the solution proposed in this paper is not only effective for reducing the local stress LL of flat panels but also effective for weakening the curved stress LL.

1. Ishinabe T, et al. Optical design of R-OCB mode full-color reflective LCD with wide viewing angle and high contrast. J. Soc. Inform. Display.1998;6:243–246. doi: 10.1889/1.1985248. [CrossRef]

2. Schadt M, et al. Optical patterning of multi-domain liquid-crystal displays with wide viewing angles. Nature.1996;381:212–215. doi: 10.1038/381212a0. [CrossRef]

7. Mao JL, et al. P119: A low voltage blue-phase liquid crystal display with concave electrode. SID Int. Symp. Dig. Tech. Pap.2016;47:1570–1572. doi: 10.1002/sdtp.11010. [CrossRef]

11. Yoneya, M. et al. Depolarized light scattering from liquid crystals as a factor for black level light leakage in liquid-crystal displays. J. Appl. Phys.98, 016106–016106–3 (2005).

13. Hsu JS, et al. Thermally induced light leakage in in-plane-switching liquid crystal displays. J. Appl. Phys.2009;105:033503. doi: 10.1063/1.3073882. [CrossRef]

14. Ishiguro M, et al. New approach to enhance contrast ratio at normal incidence by controlling the retardation of optical compensation film in vertically aligned liquid crystal displays. Jpn. J. Appl. Phys.2010;49:030208. doi: 10.1143/JJAP.49.030208. [CrossRef]

19. Jeong, H. S. et al. Liquid crystal display black light leakage correlation between VA and IPS by curvature. International Workshop on Active-matrix Flat panel Displays & Devices. IEEE, (2014).

24. Tan GJ, et al. High dynamic range liquid crystal displays with a mini-LED backlight. Opt. Express.2018;26:16572–16584. doi: 10.1364/OE.26.016572. [PubMed] [CrossRef]

27. Chen HW, et al. Pixel-by-pixel local dimming for high-dynamic-range liquid crystal displays. Opt. Express.2017;25:1973–1984. doi: 10.1364/OE.25.001973. [PubMed] [CrossRef]

33. Yoneya M, et al. Depolarized light scattering from liquid crystals as a factor for black level light leakage in liquid-crystal displays. J. Appl. Phys.2005;98:016106. doi: 10.1063/1.1948524. [CrossRef]

Influence of the slight adjustment of oxides on the structural and physico-chemical properties of thin film transistor-liquid crystal display substrate glass

Data from: Influence of the slight adjustment of oxides on the structural and physico-chemical properties of thin film transistor-liquid crystal display substrate glass

By the slight adjustment of oxides constituting thin film transistor-liquid crystal display (TFT-LCD) substrate glass, including equal mole fraction substitution of Al2O3, GeO2, B2O3, P2O5 and ZrO2 for SiO2, as well as the substitution of CaO for SrO with the total contents unchanged, the structural and physico-chemical properties of the glass was investigated by Raman spectroscopy and other measurements. The results showed that the short-range disorder brought by the substitution of GeO2, B2O3 and P2O5 for SiO2 could weaken the stability and compactness of the glass network, and the physico-chemical properties deteriorated, while the process of glass melting would become easier accordingly. The short-range disorder by the substitution of ZrO2 for SiO2 with 1% mole fraction showed a little difference with other samples. Finally, the substitution of modified cations, such as CaO and SrO, showed a smaller variation compared with the substitution of network formers. On the condition of 1% mole fraction substitution of oxides investigated, the variation of samples showed a reasonable change and the performance was basically all satisfied for the use of TFT-LCD substrate.

Thin film transistor-liquid crystal display (TFT-LCD) substrate glass is a kind of substrate for electronic display [1,2]. In order to meet the demand of the process of LCD devices, the glass needs to be alkali-free. The international representative products such as Corning Eagle XG™ and Asahi AN100™ mainly contain some conventional oxides, such as SiO2, Al2O3, B2O3, MgO, CaO and SrO [3,4]. The influence of some unconventional oxides on the structural and physico-chemical properties of alkali-free glass deserve further study for the improvement of the glass industry. For example, some glass network formers, such as GeO2 and P2O5, and the modified cations ZrO2, the substitution of them for SiO2 could play an important role in shaping the glass network and improving the performance of glass. Herein, we studied the influence of the slight adjustment of oxides mentioned above. To investigate the structural and physico-chemical properties of the glass, Raman spectroscopy, as well as some physico-chemical measurements were used to evaluate the effects of the slight adjustment of oxides.

Seven kinds of the chemical compositions of alkali-free glass for TFT-LCD substrate are summarized in table 1, wherein sample 1 is the reference sample for the other six samples, which are acquired by the slight adjustment of oxides from sample 1. The details are as follows: sample 2 is acquired by 1% mole fraction substitution of Al2O3 for SiO2 with equal total amount compared with sample 1, and the other samples are acquired in the same way as sample 2, including 1% mole fraction substitution of GeO2 for SiO2 for sample 3, 1% mole fraction substitution of B2O3 for SiO2 for sample 4, 1% mole fraction substitution of P2O5 for SiO2 for sample 5, 1% mole fraction substitution of SrO and CaO for sample 6 and 1% mole fraction substitution of ZrO2 for SiO2 for sample 7. By the slight adjustment of the oxides, the structural along with the physico-chemical properties were investigated.

Table 6 shows the logarithm volume resistivity of samples measured at 25°C and 250°C, respectively. TFT-LCD substrate glass is a kind of alkali-free glass and the alkali-earth ions are the primary conductive elements, which show a lower conductivity than alkaline ions. This is why the volume resistivity of TFT-LCD substrate glass is larger than conventional soda lime glass. At a temperature of 25°C, the logarithm volume resistivities of the TFT-LCD substrate glass is between 15.1 Ω cm and 15.9 Ω cm. When the samples were heated, the energy of alkali-earth ions increased, and the number of ions with high enough energy in the glass network that could migrate in the electric field also increased, causing the decrease of the resistivity to around 13 Ω cm at 250°C shown in table 5, which declined about 100 times compared with that at 25°C.

By the slight adjustment of oxides of the TFT-LCD substrate glass, including equal mole fraction substitution of Al2O3, GeO2, B2O3, P2O5 and ZrO2 for SiO2, as well as the substitution of CaO for SrO with the total contents unchanged, the structure and physico-chemical properties of glass was investigated. The results were as follows.(i) The architecture of the glass network did not show too much difference with the substitution of 1% mole fraction for network formers and modified cations. The low frequency bending vibration of Si–Ob in Si–Ob–Si bonds dominated in alkali-free glass, and B3+ was mainly found in the form of a [BO3] triangle owing to its inferiority to Al3+ coordinated by oxygen ions and fewer alkali-earth ions. As for the [SiO4] tetrahedron, Q3 and Q4 units accounted for the most in four kinds of [SiO4] units. With the substitution of oxides for SiO2, Q3 decreased and Q4 increased, but the disorder degree of network increased, embodied in the lower frequency shift of the Raman peak. Sample 7 with Zr4+ showed more peak shift than others, mainly owing to the high electric of Zr4+ that can significantly affect the glass network.

Data from: Influence of the slight adjustment of oxides on the structural and physico-chemical properties of thin film transistor-liquid crystal display substrate glass

A computer monitor is an output device that displays information in pictorial or textual form. A discrete monitor comprises a visual display, support electronics, power supply, housing, electrical connectors, and external user controls.

The display in modern monitors is typically an LCD with LED backlight, having by the 2010s replaced CCFL backlit LCDs. Before the mid-2000s,CRT. Monitors are connected to the computer via DisplayPort, HDMI, USB-C, DVI, VGA, or other proprietary connectors and signals.

Originally, computer monitors were used for data processing while television sets were used for video. From the 1980s onward, computers (and their monitors) have been used for both data processing and video, while televisions have implemented some computer functionality. In the 2000s, the typical display aspect ratio of both televisions and computer monitors has changed from 4:3 to 16:9.

Early electronic computer front panels were fitted with an array of light bulbs where the state of each particular bulb would indicate the on/off state of a particular register bit inside the computer. This allowed the engineers operating the computer to monitor the internal state of the machine, so this panel of lights came to be known as the "monitor". As early monitors were only capable of displaying a very limited amount of information and were very transient, they were rarely considered for program output. Instead, a line printer was the primary output device, while the monitor was limited to keeping track of the program"s operation.

The first computer monitors used cathode-ray tubes (CRTs). Prior to the advent of home computers in the late 1970s, it was common for a video display terminal (VDT) using a CRT to be physically integrated with a keyboard and other components of the workstation in a single large chassis, typically limiting them to emulation of a paper teletypewriter, thus the early epithet of "glass TTY". The display was monochromatic and far less sharp and detailed than on a modern monitor, necessitating the use of relatively large text and severely limiting the amount of information that could be displayed at one time. High-resolution CRT displays were developed for specialized military, industrial and scientific applications but they were far too costly for general use; wider commercial use became possible after the release of a slow, but affordable Tektronix 4010 terminal in 1972.

Some of the earliest home computers (such as the TRS-80 and Commodore PET) were limited to monochrome CRT displays, but color display capability was already a possible feature for a few MOS 6500 series-based machines (such as introduced in 1977 Apple II computer or Atari 2600 console), and the color output was a speciality of the more graphically sophisticated Atari 800 computer, introduced in 1979. Either computer could be connected to the antenna terminals of an ordinary color TV set or used with a purpose-made CRT color monitor for optimum resolution and color quality. Lagging several years behind, in 1981 IBM introduced the Color Graphics Adapter, which could display four colors with a resolution of 320 × 200 pixels, or it could produce 640 × 200 pixels with two colors. In 1984 IBM introduced the Enhanced Graphics Adapter which was capable of producing 16 colors and had a resolution of 640 × 350.

By the end of the 1980s color progressive scan CRT monitors were widely available and increasingly affordable, while the sharpest prosumer monitors could clearly display high-definition video, against the backdrop of efforts at HDTV standardization from the 1970s to the 1980s failing continuously, leaving consumer SDTVs to stagnate increasingly far behind the capabilities of computer CRT monitors well into the 2000s. During the following decade, maximum display resolutions gradually increased and prices continued to fall as CRT technology remained dominant in the PC monitor market into the new millennium, partly because it remained cheaper to produce.

There are multiple technologies that have been used to implement liquid-crystal displays (LCD). Throughout the 1990s, the primary use of LCD technology as computer monitors was in laptops where the lower power consumption, lighter weight, and smaller physical size of LCDs justified the higher price versus a CRT. Commonly, the same laptop would be offered with an assortment of display options at increasing price points: (active or passive) monochrome, passive color, or active matrix color (TFT). As volume and manufacturing capability have improved, the monochrome and passive color technologies were dropped from most product lines.

The first standalone LCDs appeared in the mid-1990s selling for high prices. As prices declined they became more popular, and by 1997 were competing with CRT monitors. Among the first desktop LCD computer monitors was the Eizo FlexScan L66 in the mid-1990s, the SGI 1600SW, Apple Studio Display and the ViewSonic VP140vision science remain dependent on CRTs, the best LCD monitors having achieved moderate temporal accuracy, and so can be used only if their poor spatial accuracy is unimportant.

High dynamic range (HDR)television series, motion pictures and video games transitioning to widescreen, which makes squarer monitors unsuited to display them correctly.

Radius of curvature (for curved monitors) - is the radius that a circle would have if it had the same curvature as the display. This value is typically given in millimeters, but expressed with the letter "R" instead of a unit (for example, a display with "3800R curvature" has a 3800mm radius of curvature.

Display resolution is the number of distinct pixels in each dimension that can be displayed natively. For a given display size, maximum resolution is limited by dot pitch or DPI.

Dot pitch represents the distance between the primary elements of the display, typically averaged across it in nonuniform displays. A related unit is pixel pitch, In LCDs, pixel pitch is the distance between the center of two adjacent pixels. In CRTs, pixel pitch is defined as the distance between subpixels of the same color. Dot pitch is the reciprocal of pixel density.

Pixel density is a measure of how densely packed the pixels on a display are. In LCDs, pixel density is the number of pixels in one linear unit along the display, typically measured in pixels per inch (px/in or ppi).

Color depth - measured in bits per primary color or bits for all colors. Those with 10bpc (bits per channel) or more can display more shades of color (approximately 1 billion shades) than traditional 8bpc monitors (approximately 16.8 million shades or colors), and can do so more precisely without having to resort to dithering.

Refresh rate is (in CRTs) the number of times in a second that the display is illuminated (the number of times a second a raster scan is completed). In LCDs it is the number of times the image can be changed per second, expressed in hertz (Hz). Determines the maximum number of frames per second (FPS) a monitor is capable of showing. Maximum refresh rate is limited by response time.

On two-dimensional display devices such as computer monitors the display size or view able image size is the actual amount of screen space that is available to display a picture, video or working space, without obstruction from the bezel or other aspects of the unit"s design. The main measurements for display devices are: width, height, total area and the diagonal.

The size of a display is usually given by manufacturers diagonally, i.e. as the distance between two opposite screen corners. This method of measurement is inherited from the method used for the first generation of CRT television, when picture tubes with circular faces were in common use. Being circular, it was the external diameter of the glass envelope that described their size. Since these circular tubes were used to display rectangular images, the diagonal measurement of the rectangular image was smaller than the diameter of the tube"s face (due to the thickness of the glass). This method continued even when cathode-ray tubes were manufactured as rounded rectangles; it had the advantage of being a single number specifying the size, and was not confusing when the aspect ratio was universally 4:3.

With the introduction of flat panel technology, the diagonal measurement became the actual diagonal of the visible display. This meant that an eighteen-inch LCD had a larger viewable area than an eighteen-inch cathode-ray tube.

Estimation of monitor size by the distance between opposite corners does not take into account the display aspect ratio, so that for example a 16:9 21-inch (53 cm) widescreen display has less area, than a 21-inch (53 cm) 4:3 screen. The 4:3 screen has dimensions of 16.8 in × 12.6 in (43 cm × 32 cm) and area 211 sq in (1,360 cm2), while the widescreen is 18.3 in × 10.3 in (46 cm × 26 cm), 188 sq in (1,210 cm2).

Until about 2003, most computer monitors had a 4:3 aspect ratio and some had 5:4. Between 2003 and 2006, monitors with 16:9 and mostly 16:10 (8:5) aspect ratios became commonly available, first in laptops and later also in standalone monitors. Reasons for this transition included productive uses for such monitors, i.e. besides Field of view in video games and movie viewing, are the word processor display of two standard letter pages side by side, as well as CAD displays of large-size drawings and application menus at the same time.LCD monitors and the same year 16:10 was the mainstream standard for laptops and notebook computers.

In 2010, the computer industry started to move over from 16:10 to 16:9 because 16:9 was chosen to be the standard high-definition television display size, and because they were cheaper to manufacture.

In 2011, non-widescreen displays with 4:3 aspect ratios were only being manufactured in small quantities. According to Samsung, this was because the "Demand for the old "Square monitors" has decreased rapidly over the last couple of years," and "I predict that by the end of 2011, production on all 4:3 or similar panels will be halted due to a lack of demand."

The resolution for computer monitors has increased over time. From 280 × 192 during the late 1970s, to 1024 × 768 during the late 1990s. Since 2009, the most commonly sold resolution for computer monitors is 1920 × 1080, shared with the 1080p of HDTV.2560 × 1600 at 30 in (76 cm), excluding niche professional monitors. By 2015 most major display manufacturers had released 3840 × 2160 (4K UHD) displays, and the first 7680 × 4320 (8K) monitors had begun shipping.

Every RGB monitor has its own color gamut, bounded in chromaticity by a color triangle. Some of these triangles are smaller than the sRGB triangle, some are larger. Colors are typically encoded by 8 bits per primary color. The RGB value [255, 0, 0] represents red, but slightly different colors in different color spaces such as Adobe RGB and sRGB. Displaying sRGB-encoded data on wide-gamut devices can give an unrealistic result.Exif metadata in the picture. As long as the monitor gamut is wider than the color space gamut, correct display is possible, if the monitor is calibrated. A picture which uses colors that are outside the sRGB color space will display on an sRGB color space monitor with limitations.Color management is needed both in electronic publishing (via the Internet for display in browsers) and in desktop publishing targeted to print.

Monitors that feature an aspect ratio greater than 2:1 (for instance, 21:9 or 32:9, as opposed to the more common 16:9, which resolves to 1.77:1).Monitors with an aspect ratio greater than 3:1 are marketed as super ultrawide monitors. These are typically massive curved screens intended to replace a multi-monitor deployment.

Some displays, especially newer flat panel monitors, replace the traditional anti-glare matte finish with a glossy one. This increases color saturation and sharpness but reflections from lights and windows are more visible. Anti-reflective coatings are sometimes applied to help reduce reflections, although this only partly mitigates the problem.

Most often using nominally flat-panel display technology such as LCD or OLED, a concave rather than convex curve is imparted, reducing geometric distortion, especially in extremely large and wide seamless desktop monitors intended for close viewing range.

Newer monitors are able to display a different image for each eye, often with the help of special glasses and polarizers, giving the perception of depth. An autostereoscopic screen can generate 3D images without headgear.

The option for using the display as a reference monitor; these calibration features can give an advanced color management control for take a near-perfect image.

The Flat Display Mounting Interface (FDMI), also known as VESA Mounting Interface Standard (MIS) or colloquially as a VESA mount, is a family of standards defined by the Video Electronics Standards Association for mounting flat panel displays to stands or wall mounts.

A fixed rack mount monitor is mounted directly to the rack with the flat-panel or CRT visible at all times. The height of the unit is measured in rack units (RU) and 8U or 9U are most common to fit 17-inch or 19-inch screens. The front sides of the unit are provided with flanges to mount to the rack, providing appropriately spaced holes or slots for the rack mounting screws. A 19-inch diagonal screen is the largest size that will fit within the rails of a 19-inch rack. Larger flat-panels may be accommodated but are "mount-on-rack" and extend forward of the rack. There are smaller display units, typically used in broadcast environments, which fit multiple smaller screens side by side into one rack mount.

A stowable rack mount monitor is 1U, 2U or 3U high and is mounted on rack slides allowing the display to be folded down and the unit slid into the rack for storage as a drawer. The flat display is visible only when pulled out of the rack and deployed. These units may include only a display or may be equipped with a keyboard creating a KVM (Keyboard Video Monitor). Most common are systems with a single LCD but there are systems providing two or three displays in a single rack mount system.

A panel mount computer monitor is intended for mounting into a flat surface with the front of the display unit protruding just slightly. They may also be mounted to the rear of the panel. A flange is provided around the screen, sides, top and bottom, to allow mounting. This contrasts with a rack mount display where the flanges are only on the sides. The flanges will be provided with holes for thru-bolts or may have studs welded to the rear surface to secure the unit in the hole in the panel. Often a gasket is provided to provide a water-tight seal to the panel and the front of the screen will be sealed to the back of the front panel to prevent water and dirt contamination.

An open frame monitor provides the display and enough supporting structure to hold associated electronics and to minimally support the display. Provision will be made for attaching the unit to some external structure for support and protection. Open frame monitors are intended to be built into some other piece of equipment providing its own case. An arcade video game would be a good example with the display mounted inside the cabinet. There is usually an open frame display inside all end-use displays with the end-use display simply providing an attractive protective enclosure. Some rack mount monitor manufacturers will purchase desktop displays, take them apart, and discard the outer plastic parts, keeping the inner open-frame display for inclusion into their product.

According to an NSA document leaked to Der Spiegel, the NSA sometimes swaps the monitor cables on targeted computers with a bugged monitor cable in order to allow the NSA to remotely see what is being displayed on the targeted computer monitor.

Van Eck phreaking is the process of remotely displaying the contents of a CRT or LCD by detecting its electromagnetic emissions. It is named after Dutch computer researcher Wim van Eck, who in 1985 published the first paper on it, including proof of concept. Phreaking more generally is the process of exploiting telephone networks.

Masoud Ghodrati, Adam P. Morris, and Nicholas Seow Chiang Price (2015) The (un)suitability of modern liquid crystal displays (LCDs) for vision research. Frontiers in Psychology, 6:303.

LG Curved UltraWide Monitors offer a large panoramic view and 4-screen split capability so you can see more of your work at once. The LG collection of UltraWide PC monitors include Freesync Monitors and IPS monitors. Find the best computer monitors for designers, photographers, gamers and other professionals who need more room for big ideas.

Bring your gameplay to the next level with LG UltraGear™ Gaming Monitors. Find wide monitor screens with the latest gamer-approved features like NVIDIA G-SYNC™ compatibility, and vibrant IPS monitor display.

TOKYO, November 26, 2018-Mitsubishi Electric Corporation (TOKYO: 6503) announced today that it has established mass-production technology for a new curved (concave) color TFT-LCD module that combines environmental ruggedness to withstand extreme temperatures and an attractive design, making it ideal for use in automobiles and leisure boats. The module offers a curvature radius from 700mm to less than 1,000mm and optical performance equivalent to that of flat screens. Mitsubishi Electric is now accepting orders for the new module.

New mass-production technology ensures fast, high quality production with one-stop solution covering everything from TFT panel production to bonding of curved cover glass

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey