tft display failure brands

The display LCD TFT is a kind of display screen that we are familiar with. Many intelligent terminal products use display LCD TFT. Liquid crystal is the most important part of display LCD TFT. Liquid crystal is a physical form, and this physical form can be used as a key factor in display by sorting. To understand the quality of display LCD wholesale tft module, we generally understand from the specific parameters. So what if the display LCD TFT is blurred? Now let Proculus introduce to you.

The LCD TFT display which becomes blurred and indistinct is divided into two cases: one is the display LCD TFT before installation, and the other is the display LCD TFT after a period of use. If you want to buy lcd module, you should the reasons for these two different time periods are also completely different.

Generally, the display LCD TFT is blurred before installation, which is likely to be the reason for the display LCD TFT itself. We generally check whether the driver is normal, and whether there is a problem with the chip and wiring. It is possible that there are some defects in the design of display LCD TFT, which leads to the blurred screen of display LCD TFT. This kind of situation needs to carry on the internal analysis to the TFT LCD display supplier and obtains the concrete solution.

There is another situation mentioned earlier, that is, it has been used for a period of time after installation, which leads to the blurring of the display LCD TFT. We need to check whether the connection with the motherboard is normal, whether the picture shows signs of jitter, whether the image can be seen clearly, and whether the tightness of the whole machine is poor, resulting in dust or water in the place where the motherboard is connected to the TFT LCD screen, all of which are likely to cause TFT LCD blurred screen. This kind of analysis should be combined with the TFT LCD screen itself, motherboard, structure and so on, and the steps are more complex.

The above content is the introduction to the treatment method of TFT LCD screen. With the continuous increase of TFT LCD display supplier, the competition in TFT LCD industry is becoming more and more fierce. The quality of many TFT LCD manufacturers is also uneven, and there is no lack of many black-hearted manufacturers to simplify the production process for profit, resulting in a lot of bad phenomena in the products. Therefore, we still have to pay more attention to the choice of TFT LCD suppliers.

The LCD TFT screens are built of thin-film transistors. The transistor is produced by chemical vapor deposition (CVD), based on the use of liquid hydrogen mixture and silicon mixture in an organic solvent, and using the rotation application method of the thin semiconductor.

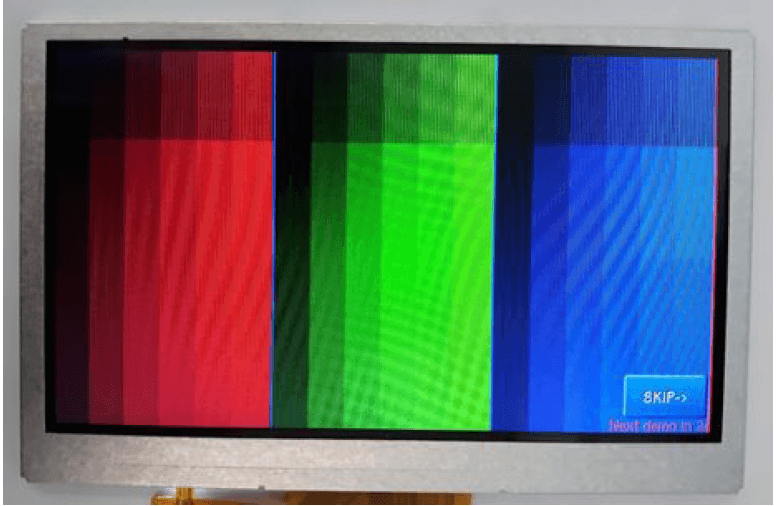

In the TFT matrix, each pixel is controlled by four transistors, whereone of them is responsible for brightness, and three remain for basic color (red, blue, green). As a result, this solution allows the high resolution, better color and generally higher parameters of displayed images – comparing to common LCD matrix.

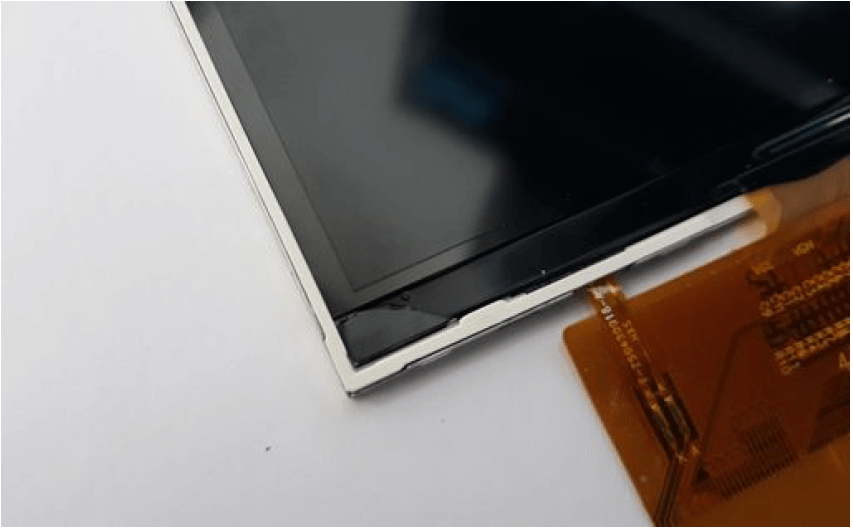

Because of the material the TFT is built from, which isglass, TFT displays havelow mechanical toughness,so can be easily damaged. The most popular damage of TFT is:violation of liquid crystal structure – „spilling liquid crystal”,

The majority of damage occurs during the assembly process in the end user devices. Too much pressure on the fragile TFT construction can damage the structure of the liquid crystal or electric lines.

We recommend that you are always careful during the process of assembling the module. This special treatment is necessary to protect the matrix of the display against being hit or put under too much pressure.

The module can be held strictly by the housing, and the unnecessary thrust on display should be avoided. The disassembling of the display housing is not recommended, because this process is very destructive and in most cases, it will leave you with a damaged TFT .

Over the years, LCD modules and LCD displays have grown in popularity. Companies in many different industries, including but not limited to the medical, automotive, consumer, food services, industrial, and technology sectors rely on at least one TFT LCD module or TFT LCD display on a daily basis. Although touchscreens are very durable and designed to withstand the hands of time, older modules and displays sometimes need to be repaired. When weighing the cost of having your displays repaired, you should take the time to consider your options.

After doing some research on the cost of repairs, many business owners find that it makes more sense to have their TFT LCDs replaced. Although units may cost less to repair initially, the cost of having to repair your older displays over and over again can add up. This is because older units may need to be repaired more than once. Even if multiple repairs will not cost any additional money, repairs lead to downtime and can have a tremendous impact on your business.

Older units in need of repair can have a long-term impact on a company’s bottom line. This is because outdated displays do not perform as well as new and improved displays. As many business owners have come to discover, new and improved touchscreen technology can increase efficiency, boost productivity, and improve customer satisfaction. This a top reason why so many companies decide to have a TFT LCD display or module replaced.

If you are thinking about having your older touchscreens repaired, then you should consider how having newer technology in place will help your business grow. Focusing strictly on the cost of replacing your displays can have a long-term impact on your business in more ways than one. For better results, you should consider all of the benefits of having new custom touchscreens specifically manufactured for your business. Ultimately, having new and improved displays in place for your employees and customers to use will be a business decision that pays for itself over time.

Vin: PWB input voltage (12V)VDD: ASIC, source IC, gate IC driving power (3.3v)VGH: TFT component switching voltage (~30V)VGL: TFT component turn-off voltage (~ -6v)VAA: step control voltage (~17V)VCOM: liquid crystal reversal reference voltage (~7V)

5. #If there is no display change in pressing, confirm whether ITO is damaged under the OM microscope, or pin signal waveform corresponding to needle COF.

Lamp line is broken Replace the lamp tubing Depending on the backlight structure, there will be different results. The failure of the performance may be a point-off, or it may be a backlight with a dark band.

The above is the full text of LCD screen failure repair guide, we hope it is helpful to you. If you need to buy LCD and find a reliable LCD supplier, we suggest you to read our other great blog – How to find a reliable LCD supplier.

TFT stands for thin-film transistor, which means that each pixel in the device has a thin-film transistor attached to it. Transistors are activated by electrical currents that make contact with the pixels to produce impeccable image quality on the screen. Here are some important features of TFT displays.Excellent Colour Display.Top notch colour contrast, clarity, and brightness settings that can be adjusted to accommodate specific application requirements.Extended Half-Life.TFT displays boast a much higher half-life than their LED counterparts and they also come in a variety of size configurations that can impact the device’s half-life depending on usage and other factors.TFT displays can have either resistive or capacitive touch panels.Resistive is usually the standard because it comes at a lower price point, but you can also opt for capacitive which is compatible with most modern smartphones and other devices.TFT displays offer exceptional aspect ratio control.Aspect ratio control contributes to better image clarity and quality by mapping out the number of pixels that are in the source image compared to the resolution pixels on the screen.Monitor ghosting doesn’t occur on TFT displays.This is when a moving image or object has blurry pixels following it across the screen, resembling a ghost.

TFT displays are incredibly versatile.The offer a number of different interface options that are compatible with various devices and accommodate the technical capabilities of all users.

There are two main types of TFT LCD displays:· Twisted nematic TFT LCDs are an older model. They have limited colour options and use 6 bits per each blue, red, and green channel.

In-plane switching TFT LCDs are a newer model. Originally introduced in the 1990s by Hitachi, in-plane switching TFT LCDs consist of moving liquid pixels that move in contrast or opposite the plane of the display, rather than alongside it.

The type of TFT LCD monitor or industrial display you choose to purchase will depend on the specifications of your application or project. Here are a few important factors to consider when selecting an appropriate TFT LCD display technology:Life expectancy/battery life.Depending on the length of ongoing use and the duration of your project, you’re going to want to choose a device that can last a long time while maintaining quality usage.

Image clarity.Some TFT displays feature infrared touchscreens, while others are layered. The former is preferable, especially in poor lighting conditions or for outdoor and industrial applications, because there’s no overlay and therefore no obstructions to light emittance.

The environmental conditions make a difference in operation and image clarity. When choosing a TFT for outdoor or industrial applications, be sure to choose one that can withstand various environmental elements like dust, wind, moisture, dirt, and even sunlight.

As a leading manufacturer and distributor of high-quality digital displays in North America, Nauticomp Inc. can provide custom TFT LCD monitor solutions that are suitable for a multitude of industrial and commercial indoor and outdoor applications. Contact us today to learn more.

As a display device TFT stands for Thin Film Transistor and is used to enhance the operation and usefulness of LCD displays. An LCD is a fluidic display device that uses a crystalline filled liquid to manipulate a rear illumination polarized source by means of an electrostatic field between two thin transparent metal conductors such as indium tin oxide (ITO) in order to present an image to the viewer. This process can be used in both segmented or pixelated display devices but is found synonymous with color TFT displays.

When an LCD is used to display moving images the inherent slow rate of change between fluid states over a large number of pixel elements can be a problem due in part to capacitive effects, which causes moving image blurring. By putting a high speed LCD controlling device in the form of a thin film transistor right at the pixel element on the glass surface, the LCD image speed issue can be greatly enhanced and for all practical purposes eliminates image blurring.

Other benefits of these thin film transistors are they allow for thinner display designs and different pixel designs and arrangements to vastly improve display viewing angles.

TFT displays are found in many applications these days, from mobile devices, appliance, medical devices, instrumentation, aircraft and certainly computer display devices as well as TV’s. The addition of the thin film transistor in LCD design vastly improved the use of LCD’s in all market areas.

Gauge cluster design is a dying art. Speedometers and tachometers used to sit at the front of motorcycles like single-handed mechanical watches, projecting only the most pertinent information to the rider: vehicle speed, engine speed and the odometer. Then, like most analog things, digital became the preference and, for the most part, still is the preferred way to display even more information to riders like time, temperature, ride modes, traction control and any other minute pieces data the manufacturer deems necessary.

No one is saying having access to all that data is unnecessary or overbearing — quite the opposite. The more you can know about what’s going on with your bike the better, but, on a modern bike, all that information is more than an analog gauge can handle. So digital displays are a necessary evil, but their principal downside is they lack style, character and they all seem to look the same. However, it seems like the motorcycle industry is at a crossroads and the opportunity for unique, yet modern design is on its way back.

Thin-film-transistor liquid-crystal — or full-color TFT displays — are gaining popularity in the motorcycle industry. TFT is merely a more refined version of the well-known liquid crystal display (LCD), whose potential is already on display in the Lexus LFAand Audi’s Virtual Cockpit. And now, motorcycle manufacturers like Ducati are bringing that technology to the two-wheeled universe to exploit the benefits of a TFT display even further.

Ducati Monster Line Product Manager Stephano Trabusi explained, “TFT is more visible during the day, even in direct sunlight, the resolution is much higher than normal LCD so that you can have much more information on a display.” Given that the cockpit of a motorcycle doesn’t have the benefit of shade from a roof, more common digital and LCDs fall victim to severe glare. The Bosch system Ducati runs even goes one step further with a night mode that can tell if it’s night time, if you’re in a tunnel or a low light environment and flips the display background to black and the font white, so it’s easier to read.

Night vision is just the tip of the TFT iceberg, though. The complex levels of traction control and ride modes that come along with the Bosch system mean the screen has to be able to cycle through numerous menus and pages and display the traction control, engine modes and ABS settings once programmed. “Given that the bikes are so much more complex nowadays, they have more and more functions and more electronics; we need that higher resolution to display all that information.” And not only that but Trabusi justifies Ducati’s use of the display in the most modern way possible, “you always see the display when you’re riding, and it has to have a premium feel for a premium ride. Today, we are so used to our smartphones with color displays — it has become just so familiar. And to have this level of resolution and color on our bikes — it was common sense.”

Therein lies the problem with the Bosch system. Because it’s from a third party electronics and software company, and because it’s so close to a complete plug-and-play package, a handful of other manufacturers — BMW, KTM, Aprilia — use similar if not identical systems. So we wind up with cookie cutter displays no better than the uninspired digital systems they replaced. But thumbing through, pages, levels, toggling ride modes and taking calls via Bluetooth, it’s undoubtedly intuitive, but there’s an overwhelming sense that no one is exploiting the display for all it can do. It’s the same as getting an iPhone X and only using it for dim-lit selfies and tri-color wallpaper.

There’s no reason Ducati couldn’t create its own version of Audi’s Virtual Cockpit — between the maps, different gauge cluster layouts and creative displays, it would be like nothing else on two wheels. The creative potential is there, but until someone unlocks it, we’re stuck in this dull purgatory of right angles and primary colors.

A thin-film-transistor liquid-crystal display (TFT LCD) is a variant of a liquid-crystal display that uses thin-film-transistor technologyactive matrix LCD, in contrast to passive matrix LCDs or simple, direct-driven (i.e. with segments directly connected to electronics outside the LCD) LCDs with a few segments.

In February 1957, John Wallmark of RCA filed a patent for a thin film MOSFET. Paul K. Weimer, also of RCA implemented Wallmark"s ideas and developed the thin-film transistor (TFT) in 1962, a type of MOSFET distinct from the standard bulk MOSFET. It was made with thin films of cadmium selenide and cadmium sulfide. The idea of a TFT-based liquid-crystal display (LCD) was conceived by Bernard Lechner of RCA Laboratories in 1968. In 1971, Lechner, F. J. Marlowe, E. O. Nester and J. Tults demonstrated a 2-by-18 matrix display driven by a hybrid circuit using the dynamic scattering mode of LCDs.T. Peter Brody, J. A. Asars and G. D. Dixon at Westinghouse Research Laboratories developed a CdSe (cadmium selenide) TFT, which they used to demonstrate the first CdSe thin-film-transistor liquid-crystal display (TFT LCD).active-matrix liquid-crystal display (AM LCD) using CdSe TFTs in 1974, and then Brody coined the term "active matrix" in 1975.high-resolution and high-quality electronic visual display devices use TFT-based active matrix displays.

The liquid crystal displays used in calculators and other devices with similarly simple displays have direct-driven image elements, and therefore a voltage can be easily applied across just one segment of these types of displays without interfering with the other segments. This would be impractical for a large display, because it would have a large number of (color) picture elements (pixels), and thus it would require millions of connections, both top and bottom for each one of the three colors (red, green and blue) of every pixel. To avoid this issue, the pixels are addressed in rows and columns, reducing the connection count from millions down to thousands. The column and row wires attach to transistor switches, one for each pixel. The one-way current passing characteristic of the transistor prevents the charge that is being applied to each pixel from being drained between refreshes to a display"s image. Each pixel is a small capacitor with a layer of insulating liquid crystal sandwiched between transparent conductive ITO layers.

The circuit layout process of a TFT-LCD is very similar to that of semiconductor products. However, rather than fabricating the transistors from silicon, that is formed into a crystalline silicon wafer, they are made from a thin film of amorphous silicon that is deposited on a glass panel. The silicon layer for TFT-LCDs is typically deposited using the PECVD process.

Polycrystalline silicon is sometimes used in displays requiring higher TFT performance. Examples include small high-resolution displays such as those found in projectors or viewfinders. Amorphous silicon-based TFTs are by far the most common, due to their lower production cost, whereas polycrystalline silicon TFTs are more costly and much more difficult to produce.

The twisted nematic display is one of the oldest and frequently cheapest kind of LCD display technologies available. TN displays benefit from fast pixel response times and less smearing than other LCD display technology, but suffer from poor color reproduction and limited viewing angles, especially in the vertical direction. Colors will shift, potentially to the point of completely inverting, when viewed at an angle that is not perpendicular to the display. Modern, high end consumer products have developed methods to overcome the technology"s shortcomings, such as RTC (Response Time Compensation / Overdrive) technologies. Modern TN displays can look significantly better than older TN displays from decades earlier, but overall TN has inferior viewing angles and poor color in comparison to other technology.

Most TN panels can represent colors using only six bits per RGB channel, or 18 bit in total, and are unable to display the 16.7 million color shades (24-bit truecolor) that are available using 24-bit color. Instead, these panels display interpolated 24-bit color using a dithering method that combines adjacent pixels to simulate the desired shade. They can also use a form of temporal dithering called Frame Rate Control (FRC), which cycles between different shades with each new frame to simulate an intermediate shade. Such 18 bit panels with dithering are sometimes advertised as having "16.2 million colors". These color simulation methods are noticeable to many people and highly bothersome to some.gamut (often referred to as a percentage of the NTSC 1953 color gamut) are also due to backlighting technology. It is not uncommon for older displays to range from 10% to 26% of the NTSC color gamut, whereas other kind of displays, utilizing more complicated CCFL or LED phosphor formulations or RGB LED backlights, may extend past 100% of the NTSC color gamut, a difference quite perceivable by the human eye.

In 2004, Hydis Technologies Co., Ltd licensed its AFFS patent to Japan"s Hitachi Displays. Hitachi is using AFFS to manufacture high end panels in their product line. In 2006, Hydis also licensed its AFFS to Sanyo Epson Imaging Devices Corporation.

A technology developed by Samsung is Super PLS, which bears similarities to IPS panels, has wider viewing angles, better image quality, increased brightness, and lower production costs. PLS technology debuted in the PC display market with the release of the Samsung S27A850 and S24A850 monitors in September 2011.

TFT dual-transistor pixel or cell technology is a reflective-display technology for use in very-low-power-consumption applications such as electronic shelf labels (ESL), digital watches, or metering. DTP involves adding a secondary transistor gate in the single TFT cell to maintain the display of a pixel during a period of 1s without loss of image or without degrading the TFT transistors over time. By slowing the refresh rate of the standard frequency from 60 Hz to 1 Hz, DTP claims to increase the power efficiency by multiple orders of magnitude.

Due to the very high cost of building TFT factories, there are few major OEM panel vendors for large display panels. The glass panel suppliers are as follows:

External consumer display devices like a TFT LCD feature one or more analog VGA, DVI, HDMI, or DisplayPort interface, with many featuring a selection of these interfaces. Inside external display devices there is a controller board that will convert the video signal using color mapping and image scaling usually employing the discrete cosine transform (DCT) in order to convert any video source like CVBS, VGA, DVI, HDMI, etc. into digital RGB at the native resolution of the display panel. In a laptop the graphics chip will directly produce a signal suitable for connection to the built-in TFT display. A control mechanism for the backlight is usually included on the same controller board.

The low level interface of STN, DSTN, or TFT display panels use either single ended TTL 5 V signal for older displays or TTL 3.3 V for slightly newer displays that transmits the pixel clock, horizontal sync, vertical sync, digital red, digital green, digital blue in parallel. Some models (for example the AT070TN92) also feature input/display enable, horizontal scan direction and vertical scan direction signals.

New and large (>15") TFT displays often use LVDS signaling that transmits the same contents as the parallel interface (Hsync, Vsync, RGB) but will put control and RGB bits into a number of serial transmission lines synchronized to a clock whose rate is equal to the pixel rate. LVDS transmits seven bits per clock per data line, with six bits being data and one bit used to signal if the other six bits need to be inverted in order to maintain DC balance. Low-cost TFT displays often have three data lines and therefore only directly support 18 bits per pixel. Upscale displays have four or five data lines to support 24 bits per pixel (truecolor) or 30 bits per pixel respectively. Panel manufacturers are slowly replacing LVDS with Internal DisplayPort and Embedded DisplayPort, which allow sixfold reduction of the number of differential pairs.

The bare display panel will only accept a digital video signal at the resolution determined by the panel pixel matrix designed at manufacture. Some screen panels will ignore the LSB bits of the color information to present a consistent interface (8 bit -> 6 bit/color x3).

With analogue signals like VGA, the display controller also needs to perform a high speed analog to digital conversion. With digital input signals like DVI or HDMI some simple reordering of the bits is needed before feeding it to the rescaler if the input resolution doesn"t match the display panel resolution.

Kawamoto, H. (2012). "The Inventors of TFT Active-Matrix LCD Receive the 2011 IEEE Nishizawa Medal". Journal of Display Technology. 8 (1): 3–4. Bibcode:2012JDisT...8....3K. doi:10.1109/JDT.2011.2177740. ISSN 1551-319X.

Brody, T. Peter; Asars, J. A.; Dixon, G. D. (November 1973). "A 6 × 6 inch 20 lines-per-inch liquid-crystal display panel". 20 (11): 995–1001. Bibcode:1973ITED...20..995B. doi:10.1109/T-ED.1973.17780. ISSN 0018-9383.

K. H. Lee; H. Y. Kim; K. H. Park; S. J. Jang; I. C. Park & J. Y. Lee (June 2006). "A Novel Outdoor Readability of Portable TFT-LCD with AFFS Technology". SID Symposium Digest of Technical Papers. AIP. 37 (1): 1079–82. doi:10.1889/1.2433159. S2CID 129569963.

Kim, Sae-Bom; Kim, Woong-Ki; Chounlamany, Vanseng; Seo, Jaehwan; Yoo, Jisu; Jo, Hun-Je; Jung, Jinho (15 August 2012). "Identification of multi-level toxicity of liquid crystal display wastewater toward Daphnia magna and Moina macrocopa". Journal of Hazardous Materials. Seoul, Korea; Laos, Lao. 227–228: 327–333. doi:10.1016/j.jhazmat.2012.05.059. PMID 22677053.

The new line of 3.5” TFT displays with IPS technology is now available! Three touchscreen options are available: capacitive, resistive, or without a touchscreen.

For over 20 years Newhaven Display has been one of the most trusted suppliers in the digital display industry. We’ve earned this reputation by providing top quality products, services, and custom design solutions to customers worldwide.

Typically, the default blame starts with the supplier. However, it could be an issue with your assembly process, the design integration between the product and the display, or even a problem with a non-display component that fails (that affects the display).

Issues with non-conforming performance, where the product no longer meets the performance specification, may be tied to a lack of quality of the components, LCD manufacturing, or in some rarer circumstance a change on the end-product that affected the LCD display.

Additionally there can be mechanical non-conformities, where there are aspects exceeding the defined tolerance as described in the specification. And in some instances, there may be variations not designated in the specification, but quite different from the original qualification units. These non-conformances are capable of affecting the fit, form, or function of the LCD display when assembled.

If your supplier has excessive component variability or possible process variability, there is the potential for a number of LCD display performance-related issues. These issues can be one-off or related to a larger batch of products manufactured together. Good serialization and traceability will help in isolating these occurrences and get to the root cause quickly.

While out-of-the-box nonconformance is typically the responsibility of the supplier, but it becomes a little more ambiguous when the non-conformance is not covered specifically by the governing specification. In this case, common sense and reasonable expectations of variation, the concept of the TEAM is considered. But at the end of the day, the LCD displays need to work in the finished product, and both parties should take the responsibility together to help get to the most efficient solution.

On the other hand, you need to be aware that performance degradation is sometimes caused by a change in another component upstream of the LCD display. Sometimes, a non-display component that is malfunctioning or is incompatible and interfaces with the display may cause the display to exhibit irregular behavior or render it inoperable altogether.

To verify this, swap displays to a fully functioning assembly and see whether the problem follows the display. If the issue does not reappear, the cause is likely a non-LCD display component.

The likelihood of damage, or the display being non-functional from the supplier’s end, is fairly low, as it is standard to test 300%, or three times throughout the process. Additionally, the final packaging itself is subject to drop testing during the initial development phase prior to mass production to ensure a damage-free trip despite your carrier’s best efforts to drop the packaging. That means the defect is likely latent or occurred during installation into the end-product.

Unfortunately, it is common for some failures to make it through final testing. After the vibration and thermal effects from the shipping process, these defects can be exposed and result in an out of box failure at the assembly line.

This could be a manufacturing issue during the LCD display production or a quality issue with an upstream component that exposed a failure mode. In this case, fault may lie with the design itself, which indicates the need for a more robust design. Alternatively, a burn-in test process may be needed to expose potential defects prior to final inspection.

The final assembly process could also be a problem area. If the process is complicated, difficult to maneuver, or there are new operators involved there is a much higher probability of damage while assembling the LCD display into the end-product.

Performing a failure analysis is next. Then, linking that analysis to the customer’s field environment. You’ll need to determine (1) whether the failure is caused by the environment and (2) whether a product improvement can better support the application, or whether there’s a way to limit the environmental extremes.

There is also the potential for misusing the product. A good example of this is using the product in an unintended environment such as extreme moisture. Impact is another unmistakable failure mode as it can manifest itself as a broken touch panel or cracked LCD glass.

Engineers tell us getting TFT LCD display modules up and running from scratch is time-consuming and expensive. There is a steep learning curve, it takes their focus away from their core competencies, and little changes cause big problems related to maintaining the solution over time. The risk of higher development costs, missed production targets, and maintenance headaches cause them to look for something other than a home-grown solution. So they turn to Reach Technology TFT LCD display modules.

Ms.Josey

Ms.Josey

Ms.Josey

Ms.Josey